Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

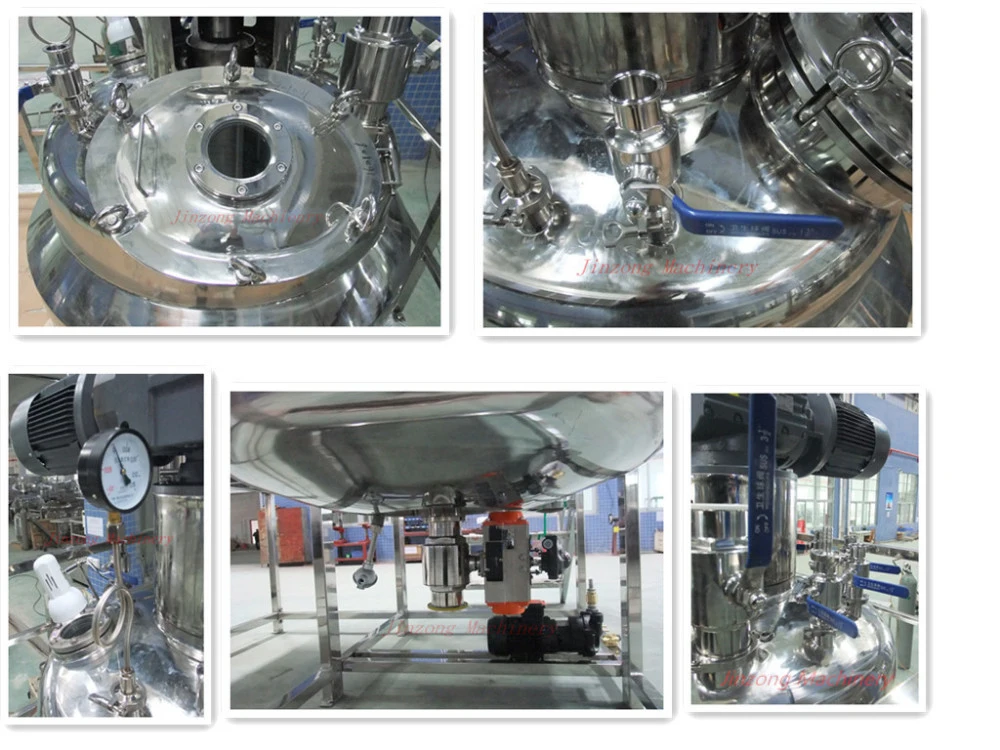

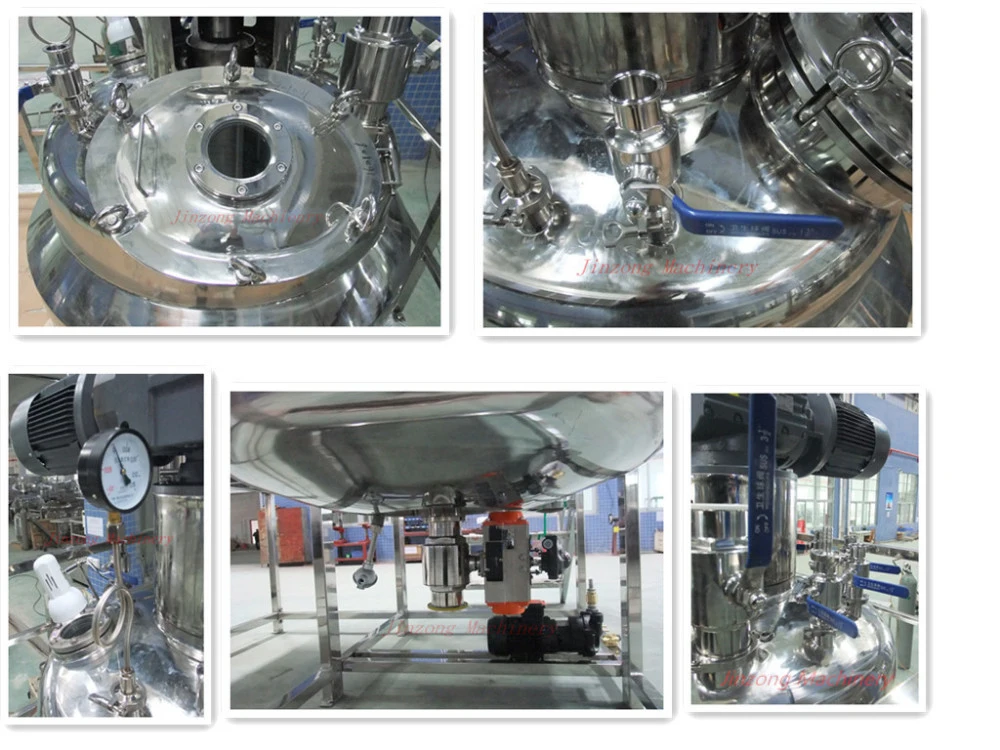

Automatic Ointment Manufacturing Plant Emulsifying Mixing Tanks

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

| Warranty | 1 Year | Trademark | JINZONG |

| Transport Package | Wooden Case | Specification | SUS304, 316L |

| Origin | Guangdong | HS Code | 8474900000 |

Automatic Ointment Manufacturing Plant Emulsifying Mixing tanks

Ointment Manufacturing Plants are ideal for the pharmaceutical and cosmetic industries for the production of ointment, creams, tooth paste, lotions and other emulsions and homogenizations.

Fully automatic Ointment, Cream, Tooth Paste, Gel manufacturing plant consisting of

Predetermined water phase vessel.

Pre determined oil, wax, petroleum jelly phase vessel.

Vacuum Homogenizer Mixer vessel.

Vacuum Pump

Storage vessel

Interconnecting pipeline.

Transfer Pumps (Bump Pump, Lobe Pump & Metering pumps)

Integrated automatic control panel.

Working Platform

To ease cleaning, efficiency of agitators, ease of maintenance.

The combined action of horizontal blade and specially designed anchor ensures most efficient mixing with shearing action of homogenizer, important when working with viscous products. Ointment plant comprises components such as manufacturing vessel and agitators with flush bottom valve, wax/water phase vessel with side mounted fast speed stirrer, flush bottom valve and conical filter, manufacturing vessel with double speed anchor and fast speed emulsifier fitted with mechanical seal, lifting pneumatically for manufacturing vessel, spray ball on top cover for cleaning main vessel, monitoring of the product temperature with digital indicator on panel, electric control panel board with all necessary controls.

Features :

Design compliance with cGMP

Integrated Cleaning in Place-CIP.

Sterilizing In Place-SIP as an Option.

Batch Size

Available model 50 Liter to 30000 Liter working Capacity.

Materials

Product Contact SUS 316L.

Food Grade silicon rubber for seal.

Ointment Manufacturing Plant is very useful for creams, lotions, gels, shampoos, tooth pastes and such preparations.

Project case

Ointment Manufacturing Plants are ideal for the pharmaceutical and cosmetic industries for the production of ointment, creams, tooth paste, lotions and other emulsions and homogenizations.

Fully automatic Ointment, Cream, Tooth Paste, Gel manufacturing plant consisting of

Predetermined water phase vessel.

Pre determined oil, wax, petroleum jelly phase vessel.

Vacuum Homogenizer Mixer vessel.

Vacuum Pump

Storage vessel

Interconnecting pipeline.

Transfer Pumps (Bump Pump, Lobe Pump & Metering pumps)

Integrated automatic control panel.

Working Platform

To ease cleaning, efficiency of agitators, ease of maintenance.

The combined action of horizontal blade and specially designed anchor ensures most efficient mixing with shearing action of homogenizer, important when working with viscous products. Ointment plant comprises components such as manufacturing vessel and agitators with flush bottom valve, wax/water phase vessel with side mounted fast speed stirrer, flush bottom valve and conical filter, manufacturing vessel with double speed anchor and fast speed emulsifier fitted with mechanical seal, lifting pneumatically for manufacturing vessel, spray ball on top cover for cleaning main vessel, monitoring of the product temperature with digital indicator on panel, electric control panel board with all necessary controls.

Features :

Design compliance with cGMP

Integrated Cleaning in Place-CIP.

Sterilizing In Place-SIP as an Option.

Batch Size

Available model 50 Liter to 30000 Liter working Capacity.

Materials

Product Contact SUS 316L.

Food Grade silicon rubber for seal.

Ointment Manufacturing Plant is very useful for creams, lotions, gels, shampoos, tooth pastes and such preparations.

The product meets customer's expectation and now is rather popular in the industry and has a broad market prospect. The product works under an effective ERP system.

The product is well-received in the global market and enjoys a bright market prospect. The product works under an effective ERP system.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy