Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Fermentor Bioreactor for Large Scale Fermentation Production

| Condition | New | Warranty | 1 Year |

| Trademark | JINZONG | Transport Package | Wooden Pallet |

| Specification | SUS304, 316L | Origin | Guangdong |

| HS Code | 8419899090 |

We offer Fermenter/Bioreactor for various application like Biopharma, Food, Alage,, Beverage, Textile, Bio Fermenter, Microbial Cell Culture, Anaerobic, Aerobic, Biodiesel, Liquid Bio Fertilizer, Bio Pesticide, BioFuel, Enzyme, Primary metabolize, Secondary metaboliz.

What is Fermentor Bioreactor?

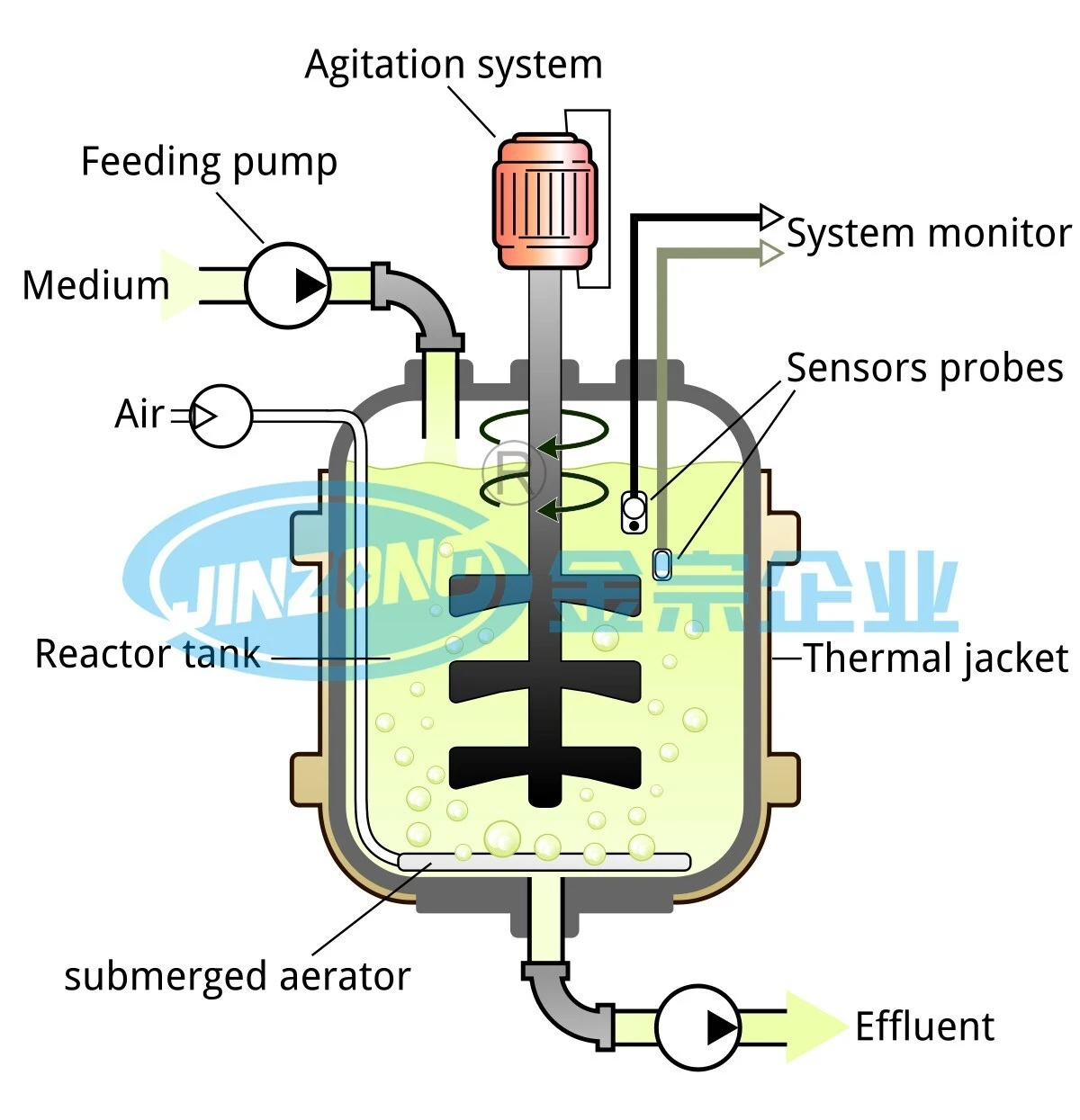

A fermentor bioreactor is a vessel or container used for the growth and cultivation of microorganisms, such as bacteria, yeast, or fungi, in a controlled environment. It provides an ideal setting for the cultivation of these organisms under conditions optimized for their growth and productivity.

Fermentor bioreactors are commonly used in various fields such as pharmaceuticals, biofuels, food and beverage production, and environmental applications. They provide a controlled environment for the cultivation of microorganisms, allowing for the production of enzymes, antibiotics, vaccines, and other biotechnological products.

The key features of a fermentor and bioreactor include mechanisms for controlling temperature, pH levels, oxygen supply, agitation, and nutrient availability to ensure optimal growth conditions for the specific microorganism being cultivated. These systems are crucial in industrial-scale production of biotechnological products and research in microbiology and biotechnology.

Fermentor bioreactor uses

The uses of fermentor bioreactors are diverse and include applications in various industries and fields. Some common uses of fermentor bioreactors are:

Biopharmaceutical Production: Fermentor bioreactors are used in the production of vaccines, antibiotics, therapeutic proteins, and other biopharmaceutical products through the cultivation of genetically engineered microorganisms or cell cultures.

Food and Beverage Industry: They are utilized for fermenting and cultivating microorganisms for the production of food additives, enzymes, flavors, and functional ingredients.

Biofuel Production: Fermentor bioreactors play a vital role in the production of biofuels such as ethanol, biodiesel, and other renewable fuels derived from microorganism-based fermentation processes.

Environmental Applications: They are used for the treatment of wastewater, bioremediation of pollutants, and the production of environmentally friendly chemicals and materials.

Research and Development: In research laboratories and academic institutions, fermentor bioreactors are used to study microbial growth, metabolic pathways, and to develop new biotechnological processes.

Industrial Biotechnology: They are employed in the large-scale production of industrial enzymes, biochemicals, and other bio-based products.

These are just a few examples of the wide-ranging applications of fermentor bioreactors, which contribute significantly to biotechnological advancements and sustainable production practices.

Benefits of Fermentor bioreactor

Fermentor bioreactors offer several benefits across various industries and applications:

Controlled Environment: They provide a tightly controlled environment for the cultivation of microorganisms, allowing precise regulation of factors such as temperature, pH, oxygen levels, agitation, and nutrient availability. This control ensures optimal conditions for microbial growth and productivity.

High Yield and Efficiency: Fermentor bioreactors are designed to maximize microbial yield and productivity, leading to efficient production of biotechnological products such as pharmaceuticals, enzymes, biofuels, and food additives.

Scale-Up Capability: They enable scalable production from laboratory to industrial scales, accommodating increased volumes of microbial cultures while maintaining consistent quality and performance.

Versatility: Fermentor bioreactors are versatile and can be adapted for various types of microorganisms (bacteria, yeast, fungi) and production processes. They support different fermentation modes including batch, fed-batch, and continuous fermentation.

Automation and Monitoring: Many modern fermentor bioreactors are equipped with automated systems for monitoring and controlling process parameters. This reduces labor-intensive tasks and enhances process reliability and reproducibility.

Product Quality and Purity: Controlled fermentation conditions contribute to improved product quality, purity, and consistency, meeting stringent regulatory standards in industries such as pharmaceuticals and food production.

Environmental Sustainability: Bioreactor and fermentor facilitate the production of bio-based products and biofuels, contributing to environmental sustainability by reducing dependence on fossil fuels and minimizing carbon footprints.

Research and Innovation: They support research and development activities by providing a platform for studying microbial physiology, metabolic pathways, and genetic engineering of microorganisms for enhanced product yields and novel applications.

Overall, fermentor bioreactors play a crucial role in advancing biotechnological processes, improving product efficiency, and driving innovation across multiple industries.

We are your source for complete production of custom machinery, including stainless steel tanks, pressure vessels and assemblies. We'll design, fabricate, machine, assemble and export pack your stainless tanks and vessels. We are stainless steel tank specialists.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)