Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Active Pharmaceutical Ingredients Intermediate Manufacturing Machine Glass Lined Reactor

| Customized | Customized | Condition | New |

| Warranty | 1 Year | Trademark | JINZONG |

| Transport Package | Plywood Case | Specification | SUS304, 316L |

| Origin | Guangdong | HS Code | 8419899090 |

What is glass lined reactor?

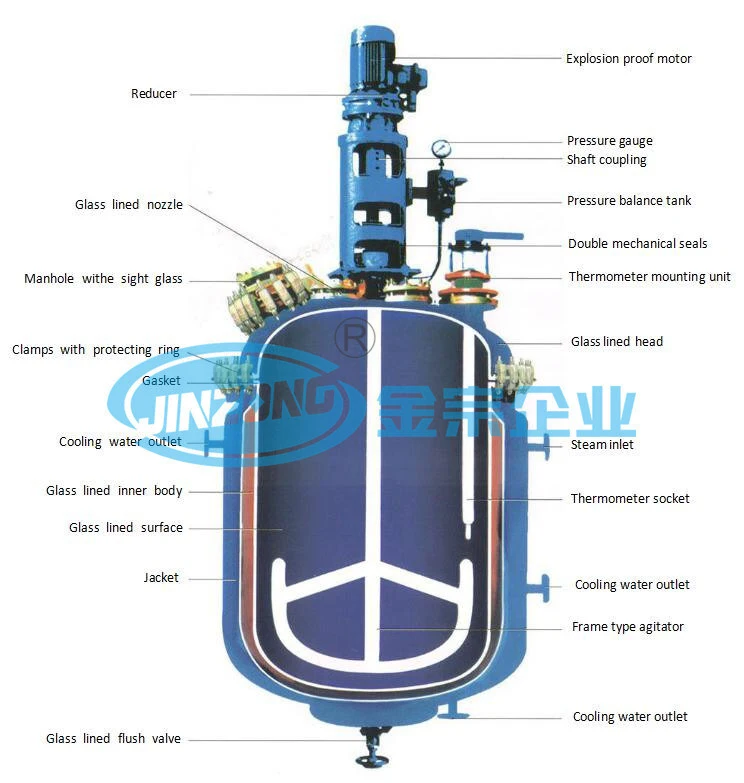

Glass-lined reactors also known as MSGL Reactor full form (Mild steel glass lined reactor), SSGLR (Stainless steel glass lined reactor) and enameled reactors are reactors made up of carbon steel having a glass lining raactor of uniform thickness.

In the chemical and pharmaceutical sector, a glass lined equipment is used given their compatibility with a wide range of chemicals. The types of glr reactor parts is a vessel with an agitator that allow the mixing of chemicals in a contained environment. The reactor can be pressurised and operate in a range of temperatures.Types of Glass Lined reactors are primarily used for carrying out critical chemical processes where corrosion resistance and chemical inertness are of critical importance.Glass Lined reactors are primarily used for carrying out critical chemical processes where corrosion resistance and chemical inertness are of critical importance.

The blue coloring of glass lined reactor types come from the cobalt that was added to the glass formulations a long time ago. Usually the choice of which color to use comes down to concerns about cleaning and what particles could be left behind.

Description

temperature abrupt change cold shock: 110ºC,

heat thermal shock 120ºC,

heating and cooling for glass-lined equipment should be slow.

2.voltage withstanding: glass-lined has good insulation. When glass is inspected by 20KV high frequency electric spark, the working surface is not conductive

3.Corrosion resistance: It can resist the corrosion of inorganic acids, organic acids, organic solvents and weak alkali of various concentrations (except hydrofluoric acid, >30% medium concentration fluoride ions and >180ºC concentrated phosphoric acid and strong alkali).

4.Non-sticky: It has a smooth and clean surface, and is not easy to bind materials. It is very suitable for food and easy-to-bind materials.

Application

It is possible to have a reaction mass that is acidic, basic, or neutral. In the case of acidic media, stainless steel reactors can cause corrosion, so we use a glass-lined reactor that has a glass lining, which is resistant to chemicals and acids, thus protecting the reactor.

In addition to being a natural and inert element, glass also prevents contamination since it does not react with any element, is easy to clean, and prevents contamination.

In the pharmaceutical, chemical, and polymer industries, glass line reactors are widely used in pharma industry.

Glass lined reactor is lined with glass which containing high silicon dioxide on the inner surface of steel containers and burned at high temperature to firmly adhered on the metal surface. It has the advantages of glass stability and metal strength. Glass lined reactor design has excellent properties of acid resistance, alkali resistance, impact resistance and temperature change resistance. It is an excellent corrosion resistance equipment. It has been widely used in chemical, petroleum, medicine, pesticide, food and other industries.This product is able to help the worker in performing his or her duties in a better way than by hands. The product has an alert function for fault detection. This product can make the work environment safer as having it means having fewer employees who perform tasks that can be dangerous and prone to injury. The product has an alert function for fault detection.

Selection criteria of glass-lined reactor, here are some of the points that we need to consider

Every MOC has an operating range of parameters such as temperature and pressure. It is necessary to check whether the selected reactor falls within the operating range.

Prior to selecting the reactor, it is crucial to ensure that the selected reactor is safe for the process. The selection of the MOC of the reactor should not pose any hazards.

It is recommended to check whether the chemicals which will be used in the reactors are compatible with each other as incompatible chemicals can severely damage the MOC and cause safety issues.

We should also consider the cost of the reactor. The chosen MOC should be cost-effective.

As the professional glass lined reactor manufacturer & suppliers, Jinzong Machinery specialized in types of glass lined reactor manufacturing.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)