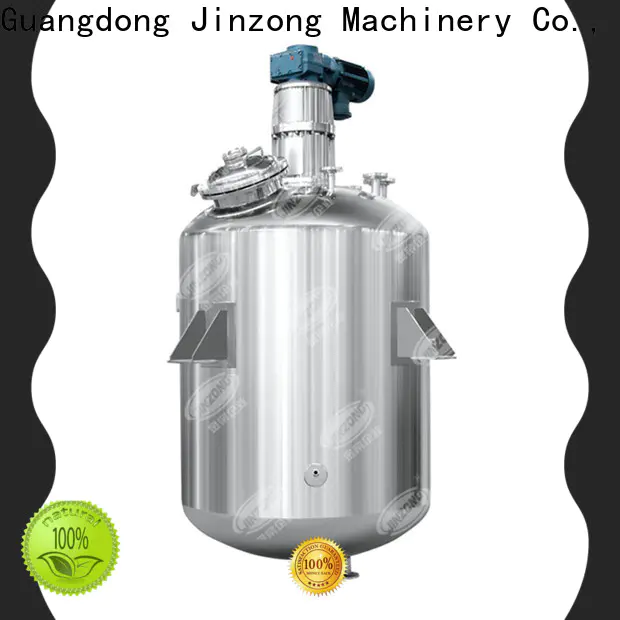

An emulsifier is a mechanical device widely used in various industries such as food, pharmaceutical, cosmetics, etc., mainly used to mix two or more immiscible liquids to form a stable emulsion. The working principle of the emulsifier is to use the shearing force between the high-speed rotating rotor and stator, so that the liquid material is forcibly sucked in and subjected to strong mechanical shearing and high-frequency hydraulic shearing, so as to achieve the effect of dispersion, homogenization and emulsification. The purpose of this paper is to provide a comprehensive user guide for operators who are new to emulsifiers.1. Basic structure of the emulsifier

The emulsifier mainly consists of the following parts:

Motor:ides the power source.

Drive system: Includes gearboxes and couplings, etc., for transmitting the power from the motor.

Working head: Usually consists of one more rotors and corresponding stators, which is the core component in the emulsification process.

Container: Choose different capacity and shape containers according to the need to load material to be processed.

Control system: Used to adjust the working parameters of the emulsifier, such as speed, time, and temperature, etc.

2. Operation steps of the emulsifier

Preparation stage

Check whether the equipment is intact and ensure that all connectors are fastened. Clean the working head and container to cross-contamination. Prepare raw materials according to process requirements and preheat (if necessary).

Install the working head

Install the appropriate model of working head the drive shaft and confirm that it is securely installed.

Pre-start check

Confirm that the power connection is correct and safe. Check the cooling system (if equipped to ensure it operates normally. Set the parameters on the control panel, such as speed, time, etc.

Operation process

Start the emulsifier and gradually increase speed to the set value. Observe the changes in the material state and make adjustments when necessary. During the emulsification process, pay attention to the changes in temperature and pressure

End and clean-up

After completing the emulsification, turn off the equipment and disconnect the power. Clean the working head and container, and perform disinf treatment when necessary.3. Maintenance and Care

Regular Inspection: Check the wear and tear of each component of the equipment and replace worn-out parts.

Lubrication Maintenance: Lubricate the moving parts according to the manufacturer's recommended schedule.

Storage Conditions: Store in a dry and vent place, away from moisture and corrosive gases.

IV. Common Issues and Solutions

Poor Emulsification Effect: Check if the work head is clogged or; adjust the speed or processing time.

Equipment Overheating: Check if the cooling system is functioning properly; reduce load or speed.

Excessive Noise: for any foreign objects that may have entered the equipment; tighten any loose parts.

Conclusion

Proper use and maintenance of the emulsifier can not only improve work but also extend the equipment's lifespan. We hope this guide will help you better master the operation techniques of the emulsifier, providing strong support for your production activities. For technical difficulties encountered in actual application, it is recommended to contact professionals for consultation and resolution promptly. You are also welcome to contact Jinchong Enterprise Consulting.

Read More>>

All Products

- PRODUCT Supplier

-

Quality Pharmaceutical produciton equipment

-

Buy Filling & Package Equipment Supplier

-

Storage Tanks and Vessels Factory

-

Quality Chemical reaction and mixing plant Supplier

-

Customized Paint & Coating Production Equipment

-

Hot 推广不显示 Supplier

-

Packeage equipment Supplier

-

Tube filling and sealing machine For sell

-

Dispersing and mixing tank and vessel Wholesale

-

Best Others Supplier

-

Best Accessories for Machinery

-

Buy RO Pure Water Equipment

-

Best Storage Tanks and Vessels

-

Labeling Machine Wholesale

-

Others Filling & Package Equipment Factory

-

Weighing filling machine Warranty

-

Best Cosmetic/food/pharmaceutical filling machine Bulk

-

Customized Turnkey project for pharmaceutica factory Factory

-

Turnkey project for food factory For sell

-

Hot Food production equipment

-

Hot Others Food and pharmaceutical Production Equipment Exporter

-

Quality Turnkey project for paint&coating factory

-

Top Miller and grinder

-

Laboratory equipment For sell

-

Best Others Paint & Coating Production Equipment Bulk

-

Buy Dissolver and disperser Supplier

-

Pharmaceutical produciton equipment Exporter

-

Certificated PRODUCT For sell

-

Chemical Processing Machine Manufacturer

-

Pharmaceutical and Food Processing Machine For sell

-

Quality Cosmetic Processing Machine

-

Paint and New Energy Processing Machine Exporter

-

Intelligent Production System Company

-

Top Pharmaceutical and Food processing machine

-

Cosmetic processing machine Bulk

-

Quality Chemical Processing Machine Company

-

Paint and New Energy processing machine Wholesale

-

Top Pharmaceutical and Food processing machine Bulk

-

Certificated Intelligent Production System Warranty

- Quality Paint and New Energy processing machine

-

Buy Pharmaceutical processing machine Exporter

-

Customized Cosmetic processing machine

-

Chemical Processing Machine Wholesale

-

Chemical Processing Machine Manufacturer