Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Wash Free Hand Disinfection Gel Production Equipment Gel Making Machine

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

| Model NO. | JZ-ET | Customized | Customized |

| Condition | New | Warranty | 1 Year |

| After-sales Service | One Year Warranty, Lifelong Maintenance | Trademark | Jinzong Machinery |

| Transport Package | Plywood Case | Specification | Depends on Capactiy |

| Origin | Guangdong, China (Mainland) | HS Code | 8479820090 |

Wash Free Hand Disinfection Gel Production Equipment Gel Making Machine

Wash Free Hand Disinfection Gel Production Equipment Gel Making Machine

Introduction:

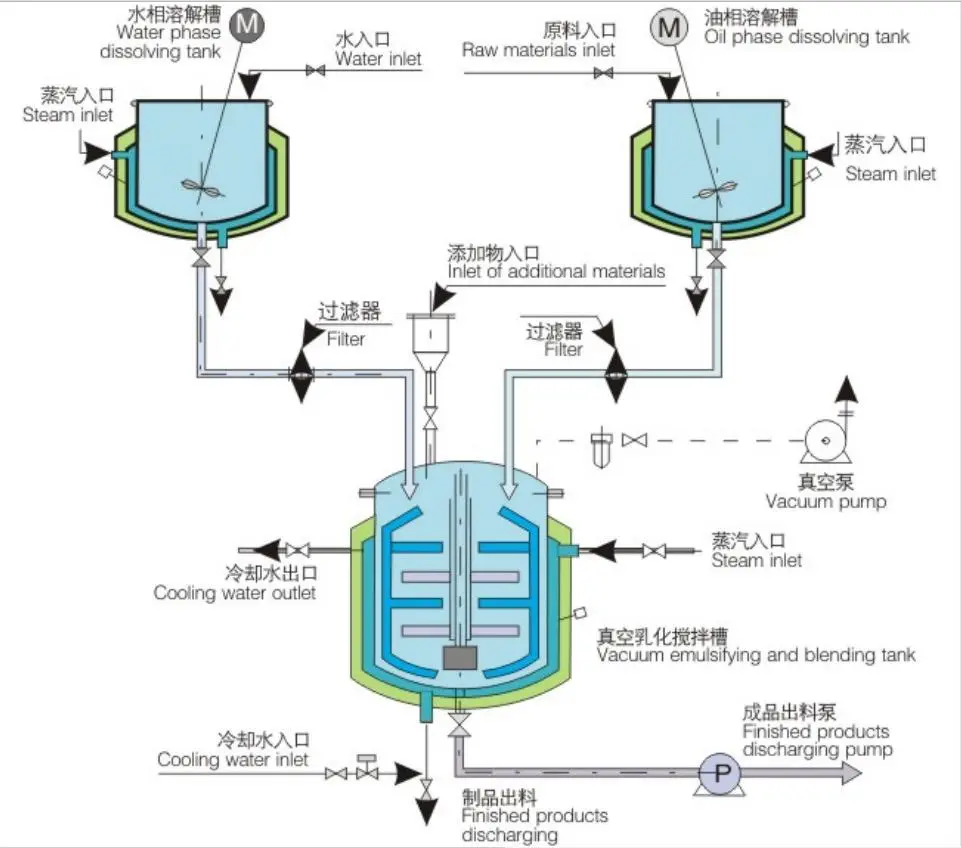

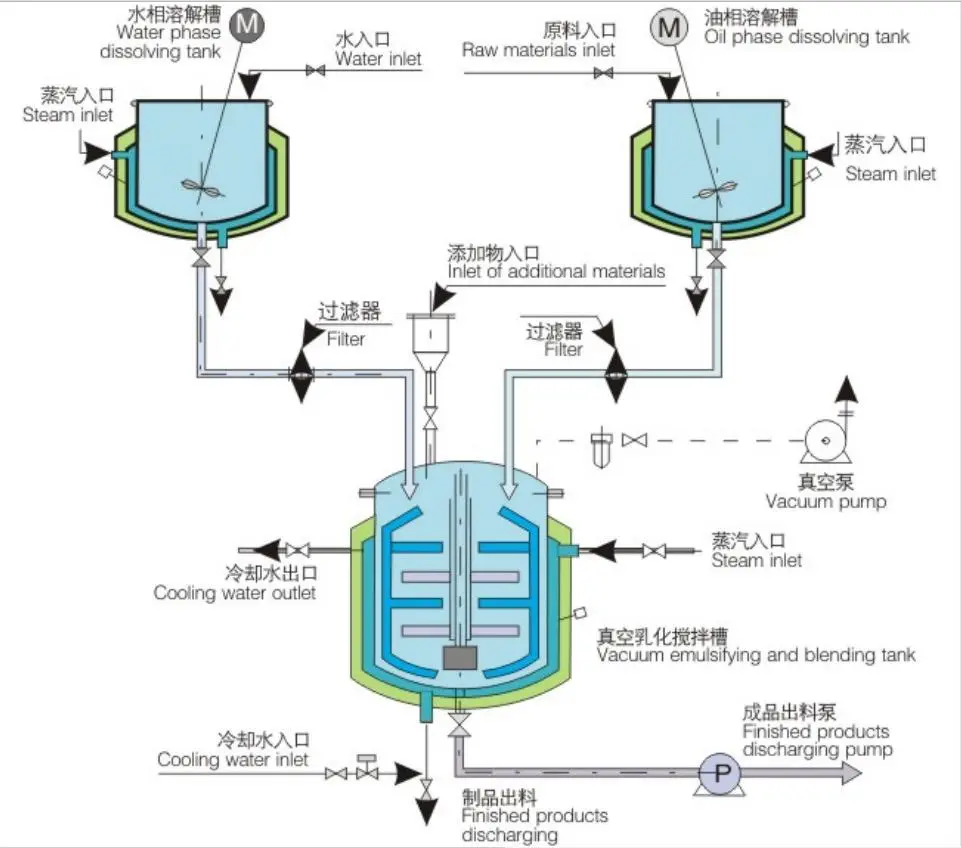

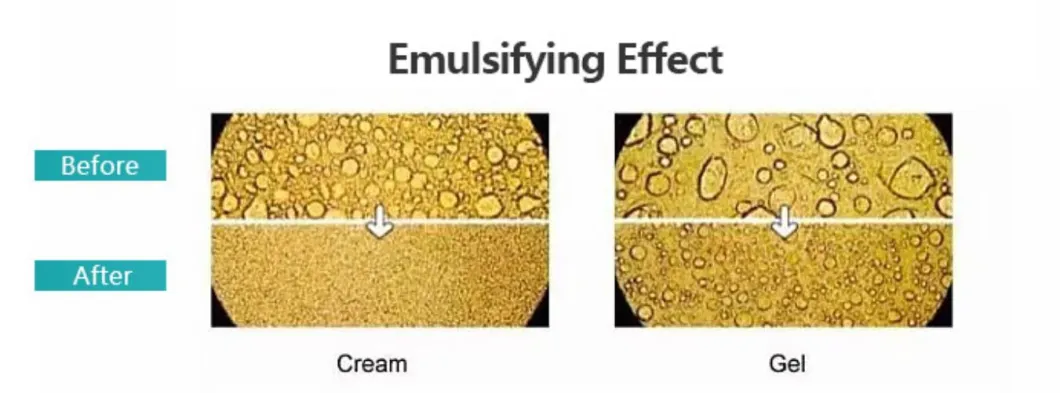

Emulsification machine is through the high-speed rotation of the homogenizing head connected with the engine to shear, disperse and impact the material. In this way, the material will become more delicate and make the oil and water blend. It is widely used in cosmetics, shower gel, sunscreen, and many other cream products. Sauce and juice in food industry. Ointment in the pharmaceutical industry. Emulsifying machine is used in petrochemical industry, paint, ink and so on.

Applications:

Emulsifying machine is widely used in many fields, such as adhesive, paint, cosmetics, food, medicine, plastic resin, printing and dyeing, ink, asphalt and so on.

Biomedicine: sugar coating, injection, antibiotic, protein dispersing agent, medicine cream, health care products, etc.

Food industry: chocolate shell, fruit pulp, mustard, dregs, salad dressing, soft drinks, mango juice, tomato juice, sugar solution, food flavors, additives, etc.

Fine chemicals: plastics, fillers, adhesives, resins, silicone oil, sealants, pastes, surfactants, carbon black, defoamers, brighteners, leather additives, coagulants, etc.

Petrochemical Industry: heavy oil emulsification, diesel oil emulsification, lubricating oil, etc.

Daily chemical industry: washing powder, concentrated washing powder, liquid detergent, all kinds of cosmetics, skin care products, etc.

Paint inks: latex paint, interior and exterior wall paint, water-based oil-based paint, nano paint, paint additives, printing ink, printing ink, textile dyes, pigments, etc.

Pesticides and fertilizers: pesticides, herbicides, pesticide emulsifiable concentrate, pesticide additives, chemical fertilizers, etc.

Nano materials: nano calcium carbonate, nano coatings, various nano material additives, etc.

Road asphalt: ordinary asphalt, modified asphalt, emulsified asphalt, modified emulsified asphalt, etc.

The working process of intermittent high shear is as follows:

1. Under the action of centrifugal force generated by the high-speed rotating rotor, the material in the figure is sucked into the working chamber axially from the upper and lower feeding areas of the working head.

2. The strong centrifugal force throws the material from the radial direction into the narrow and precise gap between the stator and rotor. At the same time, the material is initially dispersed and emulsified by centrifugal extrusion, impact and other forces.

3. A linear speed of at least 15m / s and up to 40m / S is generated at the outer end of the high-speed rotating rotor, and strong mechanical and hydraulic shearing, liquid layer friction, impact and tearing are formed, so that the materials are fully dispersed, emulsified, homogenized, broken, and ejected through the stator slot at the same time. Emulsification machine is through the high-speed rotation of the homogenizing head connected with the engine to shear, disperse and impact the material. In this way, the material will become more delicate and make the oil and water blend. Sauce and juice in food industry. Ointment in the pharmaceutical industry. Emulsifying machine is used in petrochemical industry, paint, ink and so on. The application of mixing, stirring, dispersing, homogenizing, emulsifying and grinding in the process of experiment or industrial production.

4. The material is continuously ejected from the radial direction at high speed, and the flow direction is changed under the resistance of the material itself and the container wall. At the same time, under the action of the upper and lower axial suction generated by the rotor area, two strong overturning turbulence are formed. After several cycles, the material finally completes the process of dispersion, emulsification and homogenization.

Characteristics:

Treblingmixing speed, adopts imported frequency contro.me the demand for diferent producton processes, Homogenizingstructure with Germany technology. adopts imported double side mechanicalsealing, The fastesthomogenizing speed can reach 3500 m, the highest accuracy of the blade can up to 0.2-5 um. Vacuum toremove the bubble in the material and leave it without any bacteria. alsoabsorb the material wth vacum, specially for the powder material to avoid thepowder coming out everywhere.

Advantage overview:

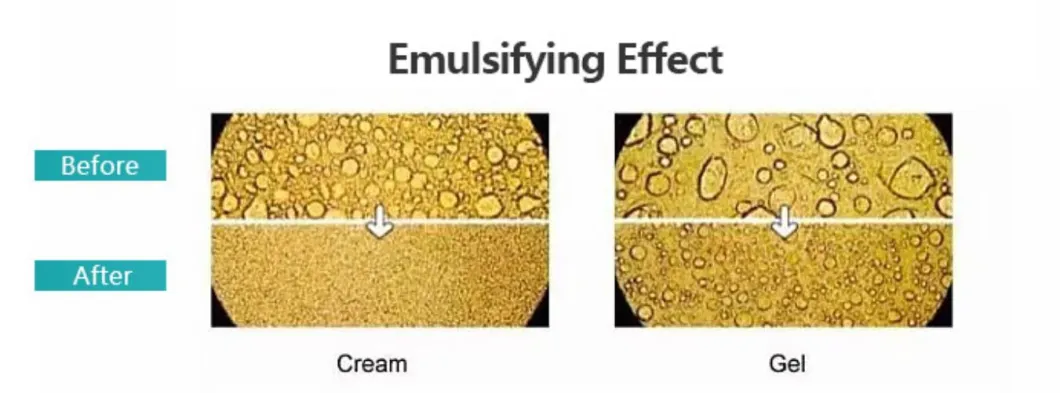

Shorten batch production time: thanks to the high efficiency of the homogenizer head and the optimized shear force transmission of the homogenization and emulsification.

Continuous high-quality production: thanks to the homogenizing head that has been repeatedly verified and designed, it optimizes the control and monitoring of the droplet size and its distribution. At the same time, the small circulation mode below the liquid surface is adopted for products that are prone to foaming.

Product stability: thanks to automatic formula control and optimized cleaning and sterilization performance.

Reduce costs: thanks to the huge difference in batch sizes that can be produced on the same equipment, as well as the efficient emulsification establishment ability.

Technical Parameter:

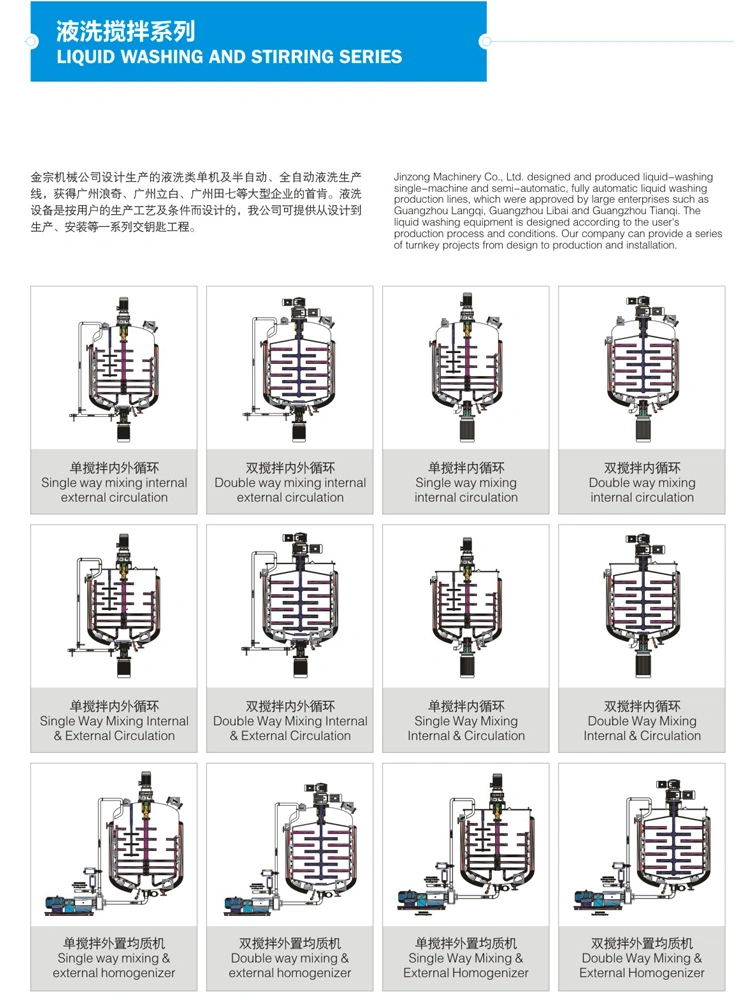

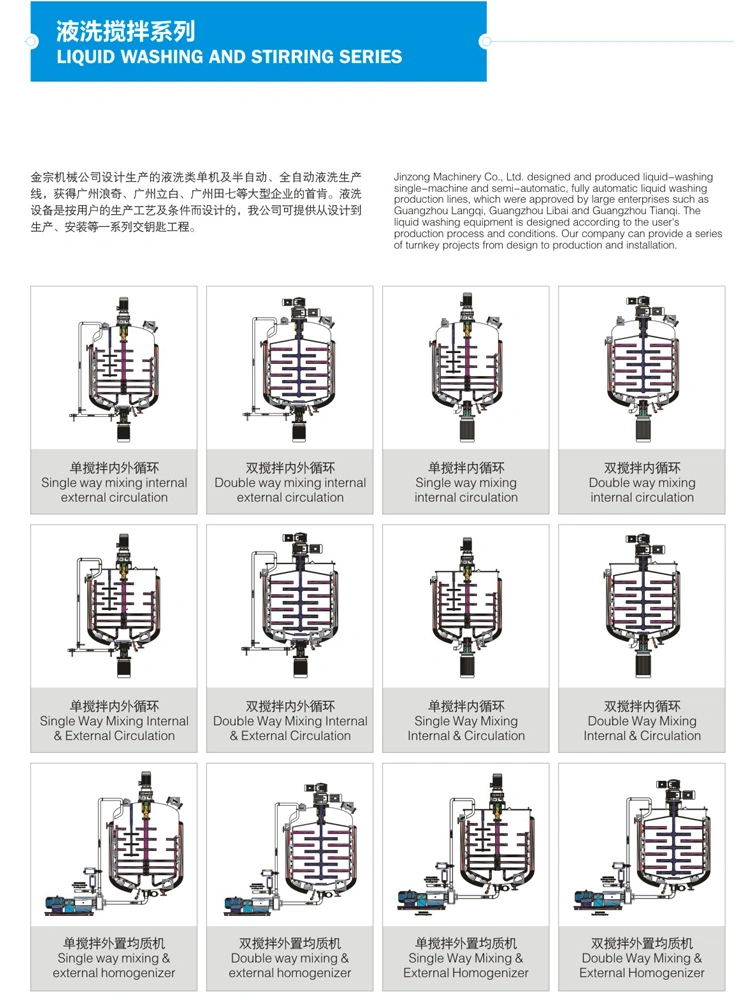

This series of machines have the mixing blades of many structural shapes for your option, and the vessel body has many shapes such as normal temperature, heating, normal pressure and vacuum, the machine has the advantages of high productivity, low power consumption, strong adaptability and broad usages, it is the ideal equipment to produce liquid detergent products.

Jinzong Machinery can provide all kinds of chemical or pharmaceutical products machines as following:

Wash Free Hand Disinfection Gel Production Equipment Gel Making Machine

Introduction:

Emulsification machine is through the high-speed rotation of the homogenizing head connected with the engine to shear, disperse and impact the material. In this way, the material will become more delicate and make the oil and water blend. It is widely used in cosmetics, shower gel, sunscreen, and many other cream products. Sauce and juice in food industry. Ointment in the pharmaceutical industry. Emulsifying machine is used in petrochemical industry, paint, ink and so on.

Applications:

Emulsifying machine is widely used in many fields, such as adhesive, paint, cosmetics, food, medicine, plastic resin, printing and dyeing, ink, asphalt and so on.

Biomedicine: sugar coating, injection, antibiotic, protein dispersing agent, medicine cream, health care products, etc.

Food industry: chocolate shell, fruit pulp, mustard, dregs, salad dressing, soft drinks, mango juice, tomato juice, sugar solution, food flavors, additives, etc.

Fine chemicals: plastics, fillers, adhesives, resins, silicone oil, sealants, pastes, surfactants, carbon black, defoamers, brighteners, leather additives, coagulants, etc.

Petrochemical Industry: heavy oil emulsification, diesel oil emulsification, lubricating oil, etc.

Daily chemical industry: washing powder, concentrated washing powder, liquid detergent, all kinds of cosmetics, skin care products, etc.

Paint inks: latex paint, interior and exterior wall paint, water-based oil-based paint, nano paint, paint additives, printing ink, printing ink, textile dyes, pigments, etc.

Pesticides and fertilizers: pesticides, herbicides, pesticide emulsifiable concentrate, pesticide additives, chemical fertilizers, etc.

Nano materials: nano calcium carbonate, nano coatings, various nano material additives, etc.

Road asphalt: ordinary asphalt, modified asphalt, emulsified asphalt, modified emulsified asphalt, etc.

The working process of intermittent high shear is as follows:

1. Under the action of centrifugal force generated by the high-speed rotating rotor, the material in the figure is sucked into the working chamber axially from the upper and lower feeding areas of the working head.

2. The strong centrifugal force throws the material from the radial direction into the narrow and precise gap between the stator and rotor. At the same time, the material is initially dispersed and emulsified by centrifugal extrusion, impact and other forces.

3. A linear speed of at least 15m / s and up to 40m / S is generated at the outer end of the high-speed rotating rotor, and strong mechanical and hydraulic shearing, liquid layer friction, impact and tearing are formed, so that the materials are fully dispersed, emulsified, homogenized, broken, and ejected through the stator slot at the same time. Emulsification machine is through the high-speed rotation of the homogenizing head connected with the engine to shear, disperse and impact the material. In this way, the material will become more delicate and make the oil and water blend. Sauce and juice in food industry. Ointment in the pharmaceutical industry. Emulsifying machine is used in petrochemical industry, paint, ink and so on. The application of mixing, stirring, dispersing, homogenizing, emulsifying and grinding in the process of experiment or industrial production.

4. The material is continuously ejected from the radial direction at high speed, and the flow direction is changed under the resistance of the material itself and the container wall. At the same time, under the action of the upper and lower axial suction generated by the rotor area, two strong overturning turbulence are formed. After several cycles, the material finally completes the process of dispersion, emulsification and homogenization.

Characteristics:

Treblingmixing speed, adopts imported frequency contro.me the demand for diferent producton processes, Homogenizingstructure with Germany technology. adopts imported double side mechanicalsealing, The fastesthomogenizing speed can reach 3500 m, the highest accuracy of the blade can up to 0.2-5 um. Vacuum toremove the bubble in the material and leave it without any bacteria. alsoabsorb the material wth vacum, specially for the powder material to avoid thepowder coming out everywhere.

Advantage overview:

Shorten batch production time: thanks to the high efficiency of the homogenizer head and the optimized shear force transmission of the homogenization and emulsification.

Continuous high-quality production: thanks to the homogenizing head that has been repeatedly verified and designed, it optimizes the control and monitoring of the droplet size and its distribution. At the same time, the small circulation mode below the liquid surface is adopted for products that are prone to foaming.

Product stability: thanks to automatic formula control and optimized cleaning and sterilization performance.

Reduce costs: thanks to the huge difference in batch sizes that can be produced on the same equipment, as well as the efficient emulsification establishment ability.

Technical Parameter:

This series of machines have the mixing blades of many structural shapes for your option, and the vessel body has many shapes such as normal temperature, heating, normal pressure and vacuum, the machine has the advantages of high productivity, low power consumption, strong adaptability and broad usages, it is the ideal equipment to produce liquid detergent products.

Jinzong Machinery can provide all kinds of chemical or pharmaceutical products machines as following:

> Hot oil hair treatment cream making mixing tank

>chemical mixing tank

>chemical mixing tank

> cosmetic mixing tank

> Pharmacy mixing tank

> Skin Cleaning products making machine

> toilet soap mixing making machine

> face wash vacuum emulsifying machine

> cleansing cream making machine

> cleansing milk making machine

> cleansing lotion making machine

> Soap and detergent manufacturing machines

> Soap and detergent mixing machines

> Laundry cleaning products making machine

> Laundry liquid making machine

> Dishwashing detergents making machine

> Dishwashing Cleaning Liquid mixing making machine

> Household cleaning products making machine

> Floor cleaners detergent making machine

> Glass cleaners detergent making machine

> wood cleaners detergent making machine

> Toilet bowl cleaners detergent making machine

> cosmetics ointment vacuum emulsifiers

> hair styling gel making mixing tank

>hair serum making mixing tank

>body care making mixing tank

>vacuum homogenizer mixer cream emulsion machine

> tomato sauce mayannaise cream vacuum blending tank mixing equipment

> PLC control automatic vacuum cream&ointment emulsifying machine

> toilet soap mixing making machine

> face wash vacuum emulsifying machine

> cleansing cream making machine

> cleansing milk making machine

> cleansing lotion making machine

> Soap and detergent manufacturing machines

> Soap and detergent mixing machines

> Laundry cleaning products making machine

> Laundry liquid making machine

> Dishwashing detergents making machine

> Dishwashing Cleaning Liquid mixing making machine

> Household cleaning products making machine

> Floor cleaners detergent making machine

> Glass cleaners detergent making machine

> wood cleaners detergent making machine

> Toilet bowl cleaners detergent making machine

> cosmetics ointment vacuum emulsifiers

> hair styling gel making mixing tank

>hair serum making mixing tank

>body care making mixing tank

>vacuum homogenizer mixer cream emulsion machine

> tomato sauce mayannaise cream vacuum blending tank mixing equipment

> PLC control automatic vacuum cream&ointment emulsifying machine

For more info, please contact us

This product is very affordable to meet the requirement as desired. The product has passed the CE certification.

In a couple of years, the product has spread out and won a high degree of recognition and reputation among overseas customers. The product has passed the CE certification.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2026 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy