*Description:

The basket is mainly composed of hydraulic lifiting system,transmission system,grinding system and so on. The hydraulic lifting system adopts the traditional hydraulic oil and the cylinder. The cylinder adopts the engineering cylinder. The cylinder is smooth and the hydraulic oil is less, And less oil spill phenomenon , hydraulic pump and motor place in the fuselage, no space, more compact, conducive to the maintenance and cleaning machine; transmission system using conventional pulley and conventional V-belt, the use of small noise process, more the use of imported bearings, long life, high speed noise small heat less; grinding system consists of all stainless steel material ,the basket stainless steel by heat treatment, high wear and corrosion resistance, the media using zirconia beads ,The bottom of the basket by the special leaves, play a pre-dispersed at the same time can make the bottom of the material up the roll, in order to achieve better grinding effect.

*Features:

1. Configure with qualified Inverter, various speed control

2. Hydraulic lifting, can be moved around

3. Integrate dispersing and grinding in one process

| Model | Capacity (L) | Power (Kw) | Speed (RPM) | Milling basket (L) | Lift stroke (mm) | Medium size (mm) |

| LS-11 | 100-400 | 11 | 0-1000 | 11 | 900 | 1.8-2.5 |

| LS-22 | 200-800 | 22 | 0-750 | 22 | 1100 | 1.8-2.5 |

| LS-30 | 300-1000 | 30 | 0-630 | 30 | 1100 | 1.8-2.5 |

| LS-37 | 300-1200 | 37 | 0-630 | 40 | 1100 | 1.8-2.5 |

◪ More than 20 years extensive experience in the machinery manufacturing in Cosmetic and cheimical biological & pharmaceutical industry.

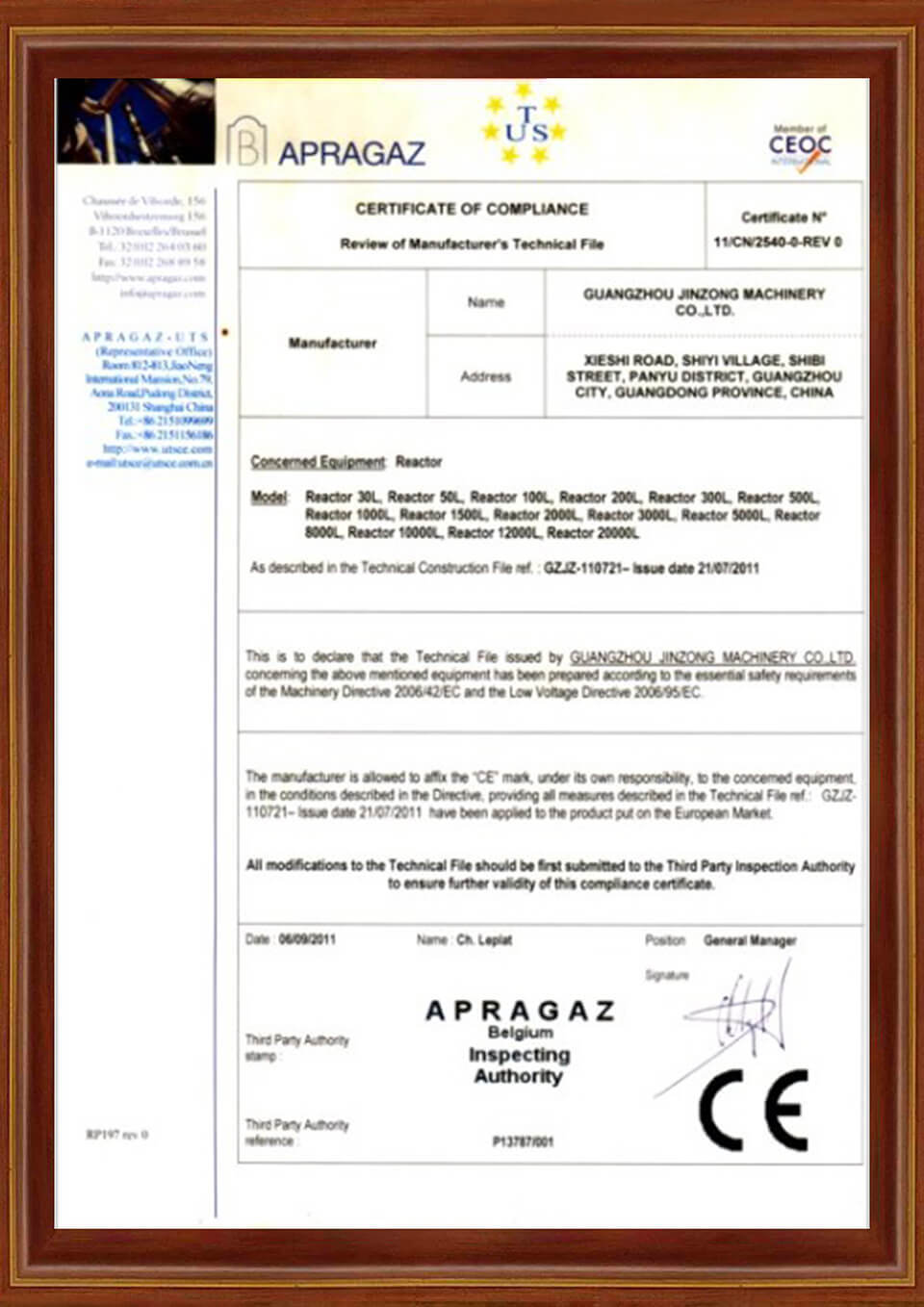

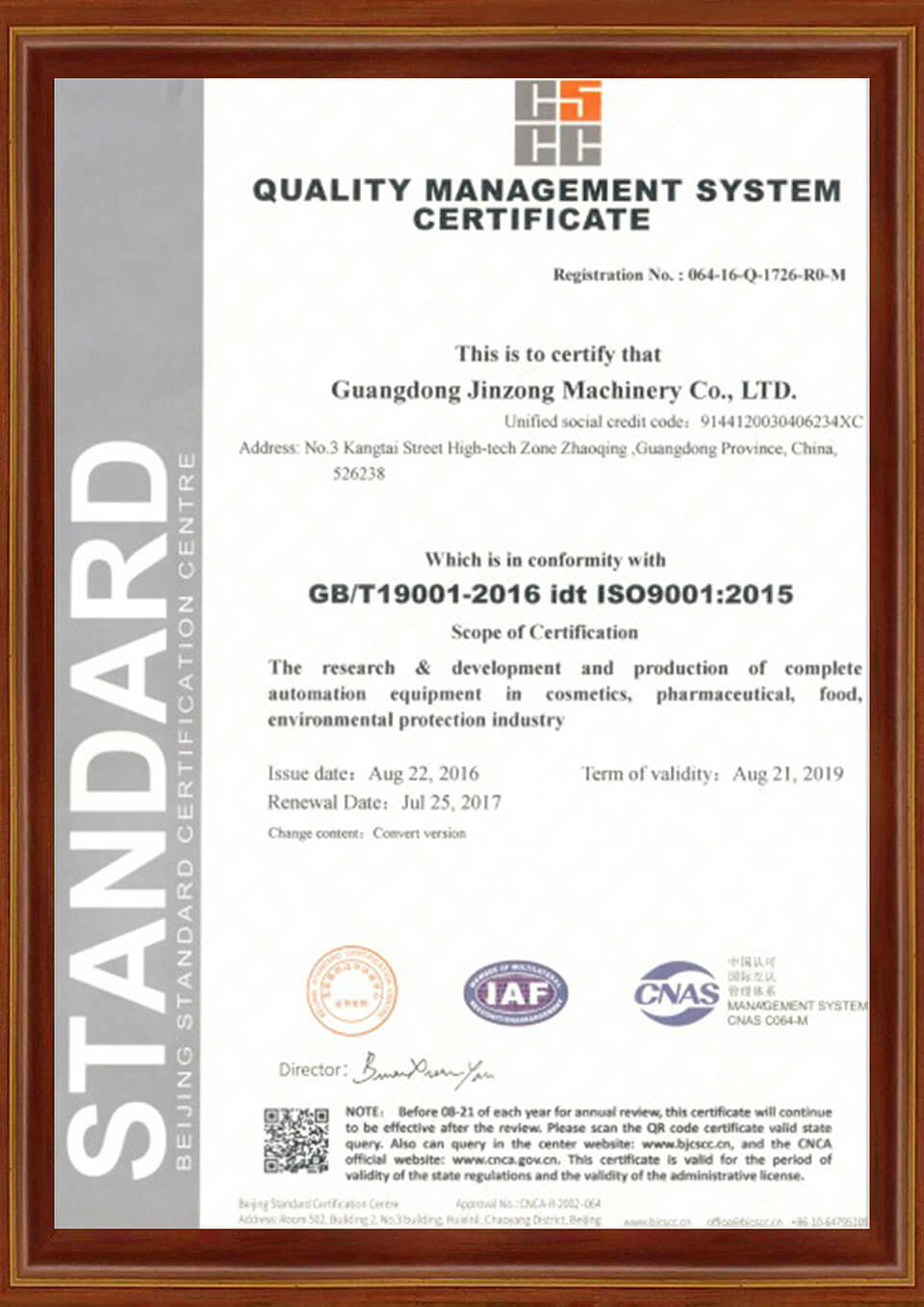

◪ Quality, 80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider. Up to now, all core machinery are with CE Certificate. We carry out products designing, manufacturing, assembling and detection fully in accordance with ISO9001-2008 Quality Management System issued by Swiss SGS Company.

◪ Good reputation in industry. Many years are awarded "defend the contract heavy credit enterprise".

◪ Have a Professional after-sales service engineering team.

◪ Large scale plant. Currently, we have 2 processing bases, Zhaoqing factory, covering a total area of more than 17,000 square meters,and Shaoguan factory,covering a total area of more than 30,000 square meters. There are more than 160 sets of processing machinery including large vertical lathe, 5-axis horizontal machining center, large planer type milling machine, automatic polishing machines etc. With the help of our strong processing capacity, we produce more than 1000 sets of equipment every year.

HD-400 3D Dry Powder Mixer Machinery

1. Application:

This machine widely used in pharmaceutical, chemical, food, metallurgy, light industries and the scientific research units, institutes, can very evenly mixed liquidity good powdery and granular material, make the mixture of material can be mixed to achieve the best state.

This machine is more mixed tube direction, and the material without the centrifugal force function, without the proportion of segregation and stratification, accumulation phenomenon, various components can have the gap of weight ratio, mixed rate is high, is at present various mixture is ideal products.

Cylinder feeding rate with big, can be as high as 90% (ordinary mix machines is only 50%), high efficiency, hybrid time is short. Cylinder with circular arc transition of all places, after precise polishing processing.

Widely used in pharmaceutical, chemical, food, light industry, electronics, machinery, mining and metallurgy, national defense industry and various scientific research units of powder, granule materials can very evenly mixed liquidity good powdery and granular material, make the mixture of materials to achieve the best mixed state..

2. Features:

Because mix barrel has many of the direction of movement, make the body material mixing barrel cross, the mixing effect is high, the evenness of 99.9% above, the maximum load coefficient 0.9 (ordinary mixer for 0.4-0.6), the mixing of short time, high efficiency. This machine mixing barrel design is unique, the barrel body wall after fine polishing, no dead Angle, no pollution materials, the material is convenient, easy to clean,simple operation.

3. Working principle:

The machine in the operation, the mixed multi-way, accelerate the flow and diffusion, solve the general mixer for centrifugal force role taken by the proportion of segregation and material accumulation phenomenon, mixed no dead Angle, can effectively ensure the best quality mixed materials.

4. Structure:

This machine is composed of the engine, transmission system, electric control system, learn a lot from sports organizations, mixing barrel components and other parts, and materials of the contact of stainless steel materials manufacturing hybrid barrels, barrel body inside and outside wall both by polishing.

5. Technical parameters:

Model | HD5 | HD15 | HD50 | HD100 | HD200 | HD400 | HD800 | HD1000 |

Barrel capacity | 5 | 15 | 50 | 100 | 200 | 400 | 800 | 1000 |

Max loading capacity | 4 | 12 | 40 | 80 | 160 | 320 | 640 | 800 |

Max loading weight | 2 | 6 | 20 | 40 | 80 | 160 | 320 | 400 |

Speed of driving shaft | 0-15r/min | |||||||

Motor power | 0.25 | 0.37 | 1.1 | 1.5 | 2.2 | 4 | 7.5 | 7.5 |

Overall dimension | 600* 1000* 1000 | 700* 1000* 1000 | 1000* 1400* 1200 | 1200* 1700* 1500 | 1400* 1800* 1600 | 1800* 2100* 1950 | 2200* 2400* 2300 | 2250* 2600* 2600 |

Total weight | 150 | 200 | 300 | 500 | 800 | 1200 | 2000 | 2500 |

6. Product Sketch:

6. Welcome to send me inquiries for the final quotations!

Pre-sale services:

Based on the clients' request and budget, we will offer equipment pictures, working site videos, plant processing diagram, assemble drawings, foundation drawings, and plant layout. Clients are welcome to visit our factory, also our equipment working site from former clients.

Sale services:

Our experienced technicians are available on the phone also the Internet, clients can get instance guidance by telephone, email, online service anytime and anywhere.

After-sale services:

Normally, the equipment warranty is 12 months since installation. To establish long term cooperation, we will regularly call and email our clients to check the equipment working condition and offer suggestions for maintenance.

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist