Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Mixing Tank with Inline Homogenizer Mayonnaise Manufacturing Machine

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

| Layout Type | Verticle | Mixing Drum Shape | Circular Groove |

| Operating type | Continuous Operating | Condition | New |

| Trademark | JINZONG | Transport Package | Wooden Case |

| Specification | SUS316L | Origin | Guangdong |

| HS Code | 8401100000 |

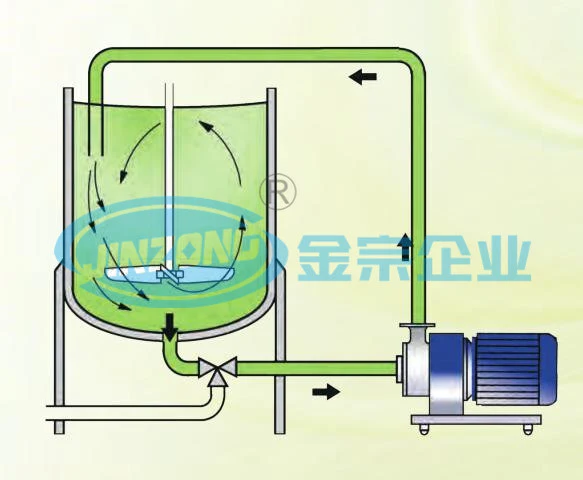

Mixing tank with Inline Homogenizer mayonnaise manufacturing machine

![Mixing Tank with Inline Homogenizer Mayonnaise Manufacturing Machine 4]()

We are a trusted manufacturer and supplier of top grade pharmaceutical and food processing machinery. With a premier aim to cater to the varied demands and requirements of our client in an efficient manner, we offer a comprehensive array of products comprising Transfer Pump, Stainless Steel tanks, Filters etc. All these products are developed in compliance with the international quality standards.

Mayonnaise machine can produce mayonnaise from eggs laid by different coop animals.The mayonnaise manufacturing equipment is used to produce the Artisan Goods, Mayonnaise from Eggs and Dinosaur Mayonnaise from Dinosaur Eggs. In Inline Homogenizer, usually called "high-shear mixers", are the most common form of dispersing/ Homogenizing/ Emulsifying mixer, the possibility of materials - Liquid or Solid passing through it, without subjected to intense hydraulic and mechanical shear actions is zero. Here suction pipe (inlet pipe) is centrally mounted & outlet is radially mounted , therefore it is physically impossible for any material to pass from inlet to outlet without exposed to agitation.

Other Details:

•Design is cGMP with all contact parts SUS316.

•Capacity up to 5,000 liters.

•Single-pass processing results in reduced batch times by up to 80% and repeatability batch-after-batch

•Energy savings when compared with in-tank mixers, colloid mills and homogenizers.

•Increased capacity when compared with colloid mills and homogenizers

•Improved product quality and shelf-life stability.

•High Differential Velocities.

•Rotor and Stator type.

•Trolley mounted, with PU Wheels and support for easy handling.

•Different type of stator (Coarse/Medium/Fine) for specific Particle size reduction.

![Mixing Tank with Inline Homogenizer Mayonnaise Manufacturing Machine 5]()

•Design is cGMP with all contact parts SUS316.

•Capacity up to 5,000 liters.

•Single-pass processing results in reduced batch times by up to 80% and repeatability batch-after-batch

•Energy savings when compared with in-tank mixers, colloid mills and homogenizers.

•Increased capacity when compared with colloid mills and homogenizers

•Improved product quality and shelf-life stability.

•High Differential Velocities.

•Rotor and Stator type.

•Trolley mounted, with PU Wheels and support for easy handling.

•Different type of stator (Coarse/Medium/Fine) for specific Particle size reduction.

APPLICATION of industrial mayonnaise machine:

•Pharmaceuticals - Making of Medicinal Formulation ,Suspension ,Syrup ,Ointment Etc.

•Food Industry : Making Purees, Pastes, Granulation etc.

•Cosmetic Industry : Making Creams,Suspension Etc.

•Bio-Technology - Making of Granulation ,Suspension ,Colloidal Solution Etc.

•Pharmaceuticals - Making of Medicinal Formulation ,Suspension ,Syrup ,Ointment Etc.

•Food Industry : Making Purees, Pastes, Granulation etc.

•Cosmetic Industry : Making Creams,Suspension Etc.

•Bio-Technology - Making of Granulation ,Suspension ,Colloidal Solution Etc.

We are a trusted manufacturer and supplier of top grade pharmaceutical and food processing machinery. With a premier aim to cater to the varied demands and requirements of our client in an efficient manner, we offer a comprehensive array of products comprising Transfer Pump, Stainless Steel tanks, Filters etc. All these products are developed in compliance with the international quality standards.

The use of this product helps achieve large-scale production and can reduce costs to levels never dreamt of before. The product can largely reduce waste materials.

This product can make the work environment safer as having it means having fewer employees who perform tasks that can be dangerous and prone to injury. The product can largely reduce waste materials.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy