Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery horizontal all packaging machinery corp high-efficiency for industary

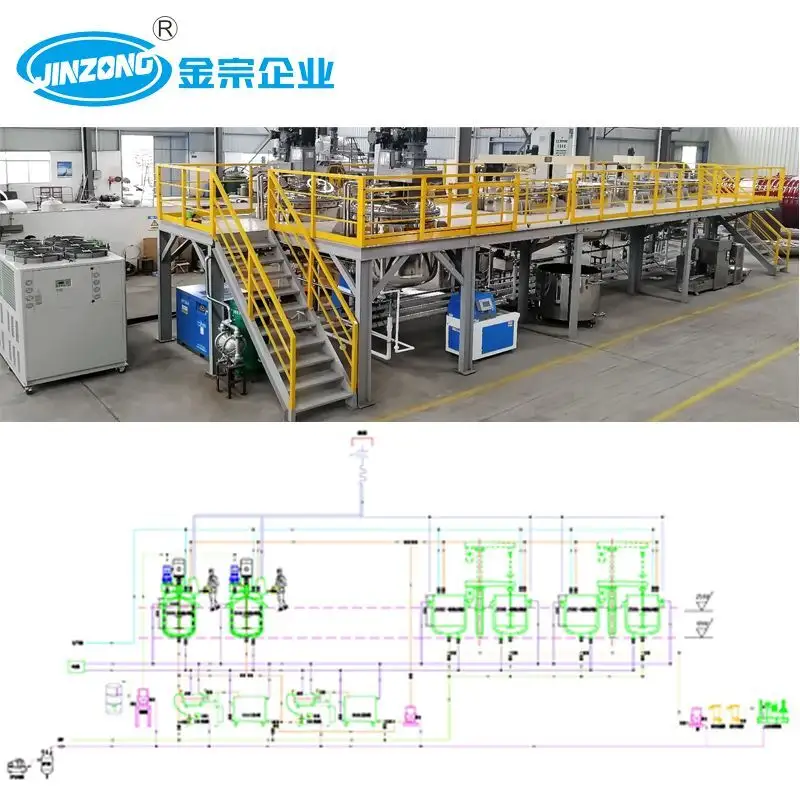

Complete metal paint production line euipment

The whole set of production line includes feeding system, outlet system, filtering system, paint mixing system, cooling system, pipeline system, electrical control system, operating platform and filling system.

1. Introduction

-Equipment for pre-mixing the solid-liquid or liquid-liquid raw materials, used for as stirrer, blender, disperser and others.

-For paint, coating, pigments, inks, detergent, lithium anode paste, textile auliliary, etc.

-Conbine milling and dispersing funciton.

-High efficiency, easy operation, maintence, cleaning and changing color.

-Applicable for independent tank operation an high/low viscosity paste.

2. Main Features

- Configure with qualified inverter, various speed control

- Hydraulic lifting, can be moved around

-Integrate dispersing and grinding in on process

-Vacuum,jacket cooling

3. Function selection

-Imported or domestic top brand inverter for option

-Custom-made design is available, such as Ex-proof, vacuum, sealed operation.

-Belt or not clamping for optional

4. Product Usages

Vacuum High Speed Disperser is widely used in coating , oil, ink ,resin, adhesive, medicine,pigment food industry etc.are widely used in papermaking, dye and pigment, paint and coating, electronics, ink, Chemical, food and cosmetics industries etc.

5. Packaging & Shipping

Packaging

1> Outer packing: plywood case

2> Inner packing: PE film wrapping overall

6.Our Services

-Engineers avaiable to service machinery overseas

- Technological support

- Guarantee: 1 year

- Custom-make is ok for us

6.1. Pre-sale service

Act as good adviser and assisant of clients enable them to get rich and generous returns on their investments.

a. Select equipment model

b. Design and manufacturer products according to client's special requirements.

c. Train technical persnonal for clients

6.2. Service during the sale

a. Pre-check and accept products adhead of delivers

b. Send photos of machines every week and send testing video

c. Help clients to draft solving plans

6.3. After-sales services

Provide considerate services to minimize client's worries

a. Assist client to prepare for the first project.

b. Install and debug the equipment

c. Train initiative to eliminate the trouble rapidly

d. Provide technical replacement

e. After-sales team will solve problems via operating and provide technical instruction

6.4. Warranty

The warranty is 12 months

Within 12 months after equipment sold, we will provide you with parts for the damaged parts(except the demages caused by wrong operation)free of charge

We will deliver t he necessary parts via express by air or sea free of charge wihthin 12 months.

7.Company Information:

We are a professional manufacturer of cosmetic,chemical& pharmaceutical machinery and equipment more than 20 years .Product lines range from:

1> Chemical Machinery: reactors, resins production line, high speed disperser, storage tank, sand mill, three rollers mill, filter, filling macihne, paint&coating production line,paint testing machines, etc.

2> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, filling machine etc.

3> Pharmaceutical Machinery: vacuum ointment machine,sanitary stainless reaction pot,alcohol deposition can, collocation tank etc.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)