Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Intermediate Pharma Manufacturing Processing Synthesis Hydrolysis Neutralization Reactor

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

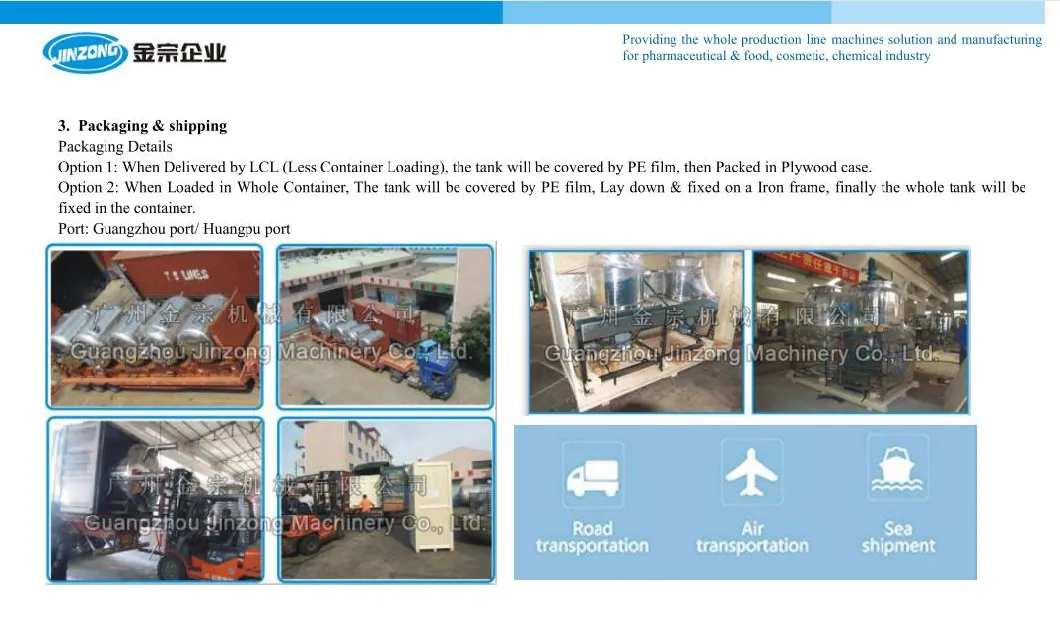

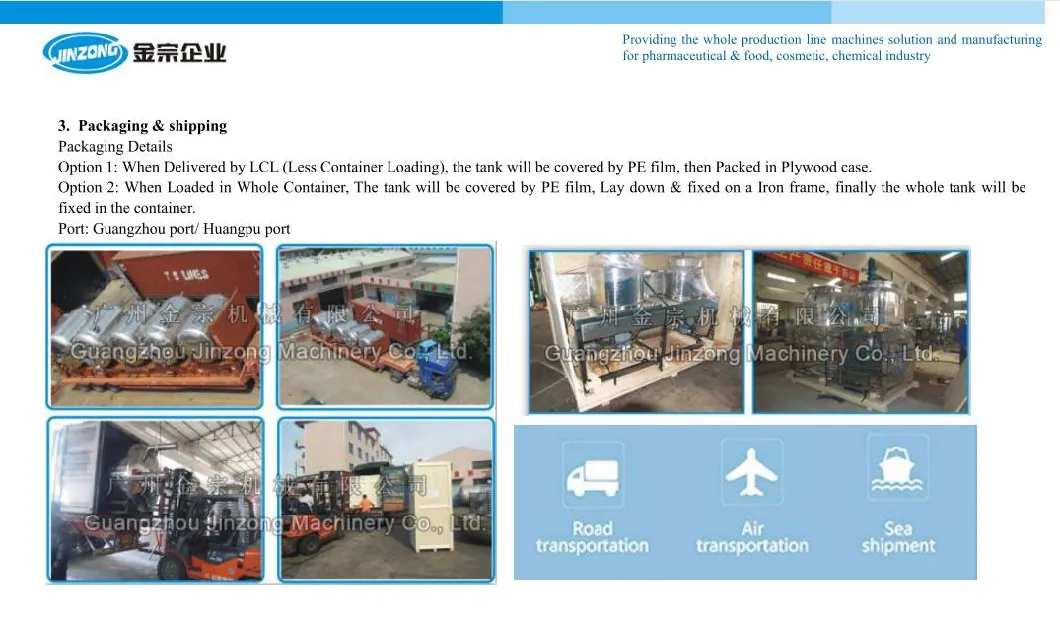

| Warranty | 1 Year | Trademark | JINZONG |

| Transport Package | Plywood Case | Specification | SUS304, 316L |

| Origin | Guangdong | HS Code | 8419899090 |

Intermediate Pharma manufacturing Processing synthesis hydrolysis Neutralization Reactor

Supply reaction vessel for pharmaceutical production, with reactor and mixer. customized.

Stainless steel reaction tank is the key equipment for API production process. Our company can provide users various reactors with engineering design, equipment model selection guide, equipment machining, equipment installation and turn-key project.

Features:

capacity: 50L-50000L, customized

Weight: customized

Cerification: CE, ISO9001

Volume: customized

Place of Origin: Guangdong, China

Brand Name: Jinzong

Material

stainless steel, high temperature stainless steel, strong acid and alkali resistant stainless steel,

Stirring Type

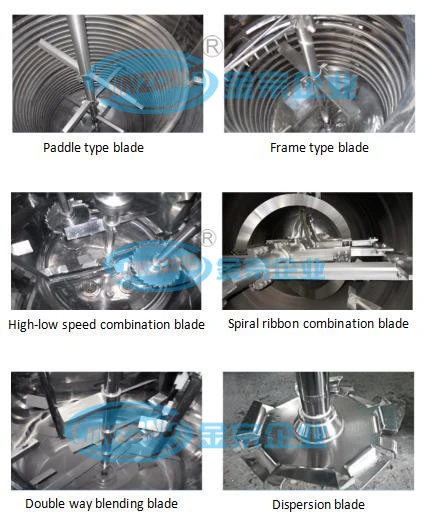

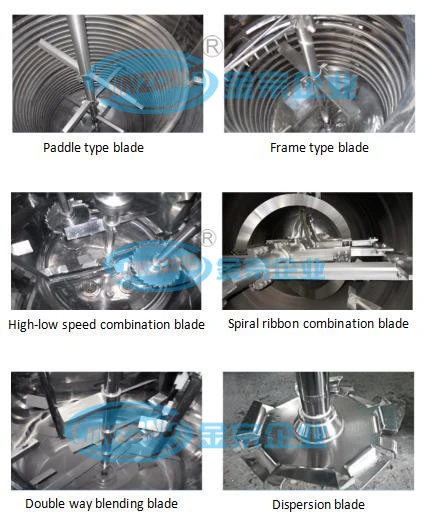

Slurry type, anchor type, frame type, push type and single (double) spiral type, and other types of blades can be designed and manufactured according to customer requirements.

Model selection reference of reaction tank

production details:

good quality stainless steel material with excellent polished treatment

Siemens agitator motor

Project case

Guangdong Jinzong Machinery Co., Ltd. is an experienced reaction production line machines manufacturer located in China. We mainly produce a variety of stainless steel reactors, glass lined reactors, electric heating reactor, hot water heating reactor, heat conducting oil circulating heating reactor, far infrared heating reactor, outer (inner) coil heating reactor jacket reactors, etc.

JINZONG MACHINERY is a stainless steel tank manufacturer of a variety of stainless steel reaction tanks, storage tanks and stainless steel pressure vessels. Our customer base includes the pharmaceutical, food, chemical, cosmetic, painting and coating industries.

Supply reaction vessel for pharmaceutical production, with reactor and mixer. customized.

Stainless steel reaction tank is the key equipment for API production process. Our company can provide users various reactors with engineering design, equipment model selection guide, equipment machining, equipment installation and turn-key project.

Features:

capacity: 50L-50000L, customized

Weight: customized

Cerification: CE, ISO9001

Volume: customized

Place of Origin: Guangdong, China

Brand Name: Jinzong

Material

stainless steel, high temperature stainless steel, strong acid and alkali resistant stainless steel,

Stirring Type

Slurry type, anchor type, frame type, push type and single (double) spiral type, and other types of blades can be designed and manufactured according to customer requirements.

Model selection reference of reaction tank

| Composition | Instructions |

| Specification (L) | 50-50000 |

| Design Pressure (Mpa) | Atmospheric Pressure or under pressure |

| Material | Carbon steel, stainless steel, enamel, graphite |

| Heating Forms | Electrical heating with medium in jacket, external half coil steam heating, external half conduction oil heating, hot water infrared heating etc. |

| Cooling Forms | Refrigeration medium in the internal pipe jacket |

| Blending Power | Model selection is made according to material viscosity, liquid-solid ratio, liquid specific gravity, solid specific gravity, solid granularity, rotation speed, paddle type, with or without baffle or internal coil. |

| Stirring blade Forms | Anchor type, frame type, flat paddle type, pitched paddle type, ribbon type, turbo type, pusher type and multiple compound type |

| Seal | Mechanical seal or stuff packing seal |

| Inner Surface Treatment | Polished or no polished |

| Discharge Valve | Flanged ball valve, open downward discharge valve and others |

| Technological Pipe Hole | Manhole, sight glass, distillation mouth, imported materials, pressure gauge port, temperature, mouth, mouth filling N2, |

production details:

good quality stainless steel material with excellent polished treatment

Siemens agitator motor

Project case

Guangdong Jinzong Machinery Co., Ltd. is an experienced reaction production line machines manufacturer located in China. We mainly produce a variety of stainless steel reactors, glass lined reactors, electric heating reactor, hot water heating reactor, heat conducting oil circulating heating reactor, far infrared heating reactor, outer (inner) coil heating reactor jacket reactors, etc.

JINZONG MACHINERY is a stainless steel tank manufacturer of a variety of stainless steel reaction tanks, storage tanks and stainless steel pressure vessels. Our customer base includes the pharmaceutical, food, chemical, cosmetic, painting and coating industries.

Compared to the use of manual labor, the tasks will be finished with a higher level of efficiency when this product is used. The product can greatly contribute to production efficiency.

There is less disappointment with the use of this product because there is high accuracy in the work done by this product. The product can greatly contribute to production efficiency.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy