Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

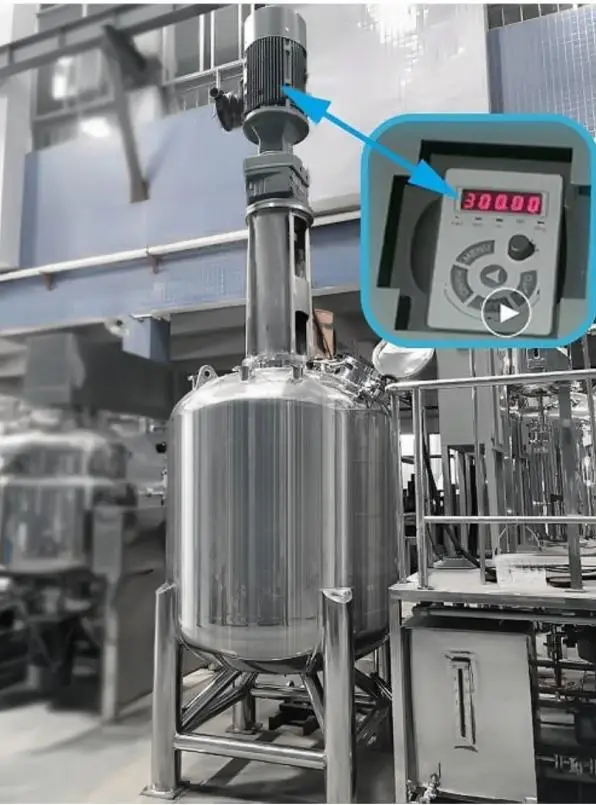

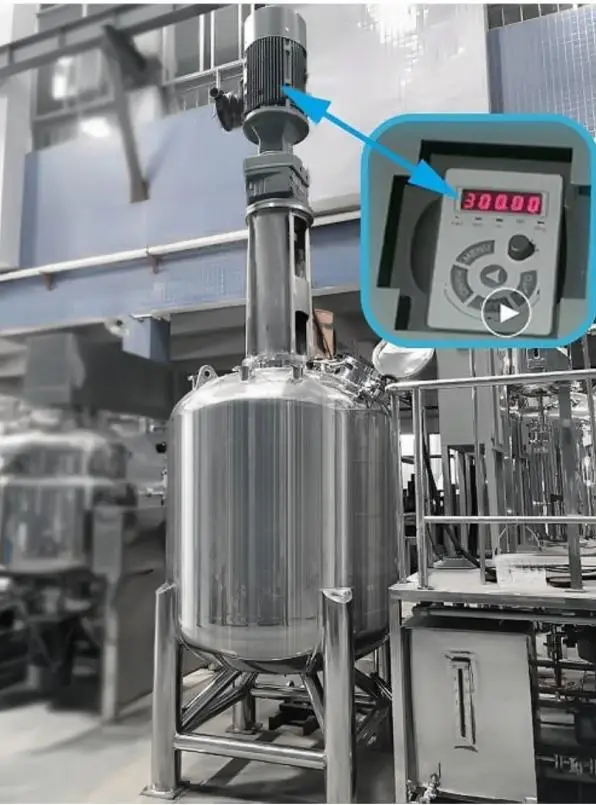

Heating & Cooling Chemical & Pharmaceutical Mixing Tanks with Stirrer

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

| Model NO. | JZ-BTA | Customized | Customized |

| Condition | New | Warranty | 1 Year |

| After-sales Service | One Year Warranty, Lifelong Maintenance | Layout Type | Vertical |

| Trademark | Jinzong Machinery | Transport Package | Plywood Case |

| Specification | Depends on Capactiy | Origin | Guangdong, China (Mainland) |

| HS Code | 8419899090 |

Heating & Cooling Chemical & Pharmaceutical Mixing Tanks with Stirrer

Anchor-type beating tank is an ideal equipment for dispersing/stirring the slurry of pharmaceutical excipients:

Anchor-type beating tank is an ideal equipment for dispersing/stirring the slurry of pharmaceutical excipients:

the equipment meets the requirements of GMP and related industry standards;

high efficiency and energy saving; stable operation;

speed: 0~300rpm/min;

low frequency maintenance;

easy to clean Disinfection,

no clean dead corners; convenient operation.

Mixing tank Features:

Material:SS304, 304L, 316 or SS316L

Design Pressure:-1 -10 Bar (g) or ATM

Work Temperature:0-200 °C

Volumes:5~30000L

We can supply single-layer, double-layer and three-layer stainless steel mixing tanks.

We also supply electrical heating, heat conductive oil heating jacket mixing tanks.

If you have any technical requirement, feel free let us know. We can design the tanks according to your requirement .

Product application scenarios:

The appearance of the product before treatment: white or almost white granular or lump, with a water content of about 60%.

Product characteristics before treatment: semi-solid materials with low viscosity, with a density of about 1.2g/cm³

Requirements after treatment: white paste-like object, uniform and fine,no graininess,solid content 10%~15%, with certain fluidity.

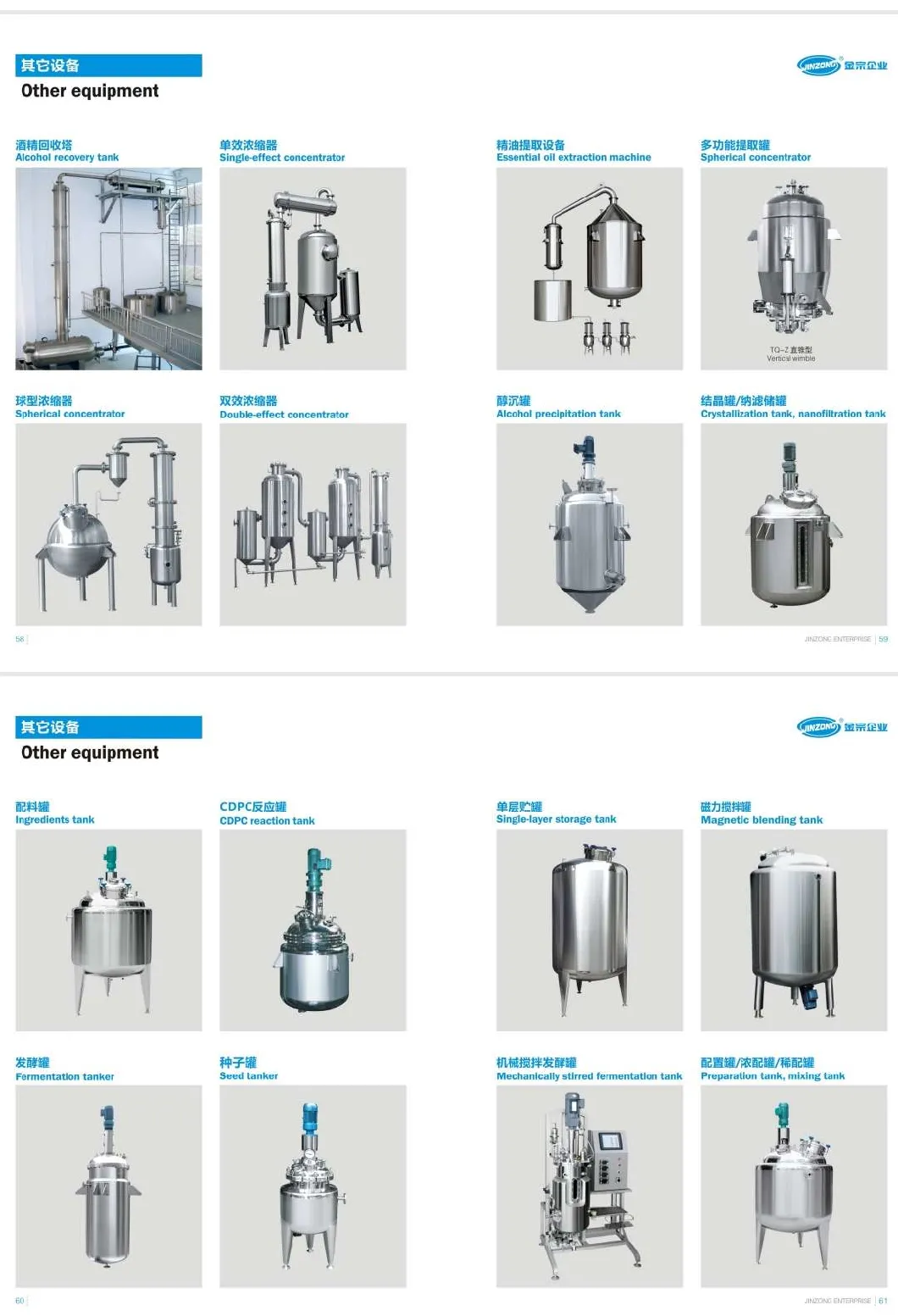

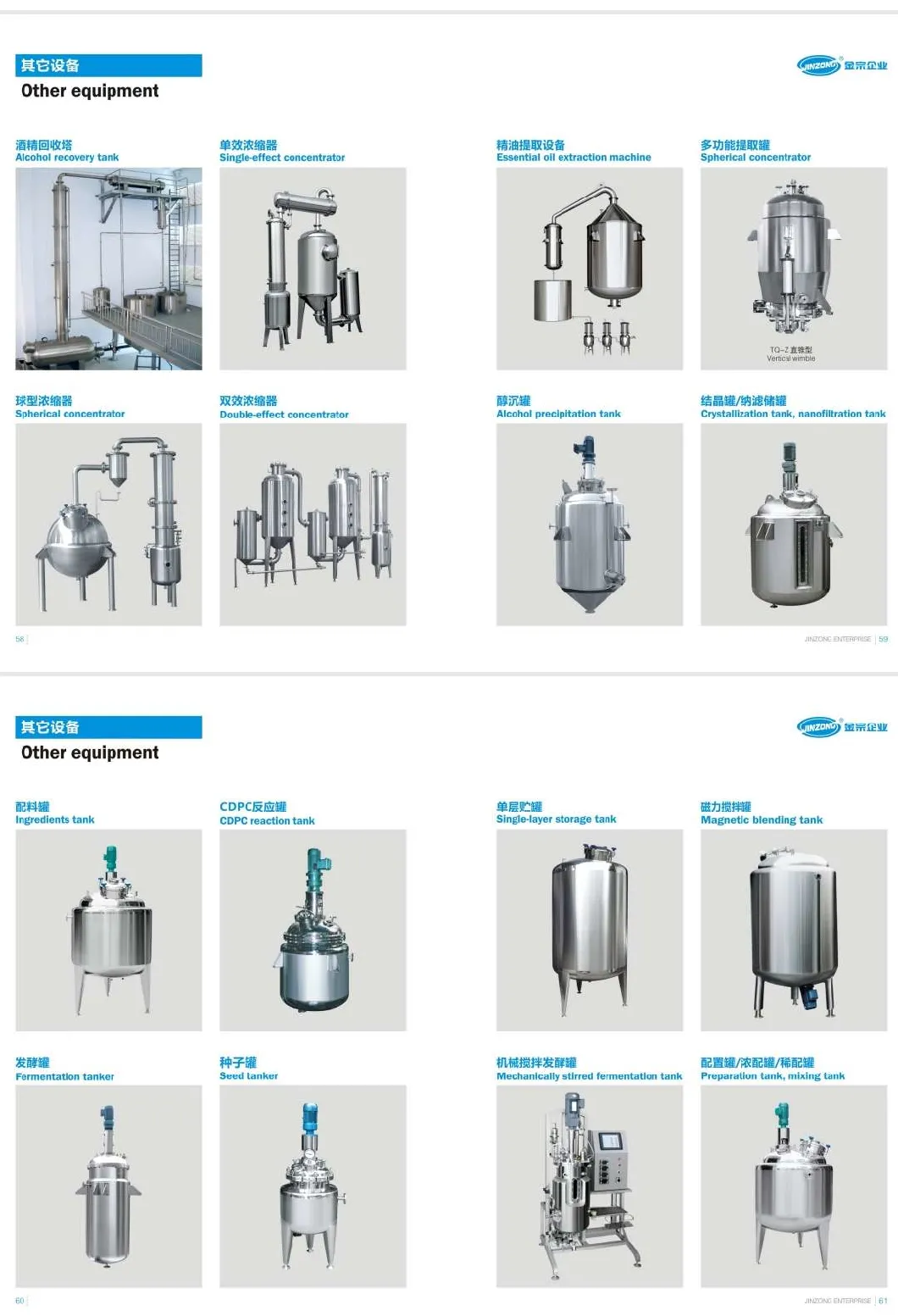

Other Storage tanks we manufactured:

These are normally supplied as tanks on wheels, although tanks with forklift channels can also be supplied. These tanks are fabricated with carbon steel or stainless steel contact parts. Volume from 50L to 10000L.

JINZONG MACHINERY offers stainless steel mixing tanks; stainless steel storage tanks; aboveground tanks (custom, horizontal, vertical); pressure tanks; heat exchangers, etc

Please contact me if you are interested and have any questions

Please contact me if you are interested and have any questions

the equipment meets the requirements of GMP and related industry standards;

high efficiency and energy saving; stable operation;

speed: 0~300rpm/min;

low frequency maintenance;

easy to clean Disinfection,

no clean dead corners; convenient operation.

Mixing tank Features:

Material:SS304, 304L, 316 or SS316L

Design Pressure:-1 -10 Bar (g) or ATM

Work Temperature:0-200 °C

Volumes:5~30000L

We can supply single-layer, double-layer and three-layer stainless steel mixing tanks.

We also supply electrical heating, heat conductive oil heating jacket mixing tanks.

If you have any technical requirement, feel free let us know. We can design the tanks according to your requirement .

Product application scenarios:

The appearance of the product before treatment: white or almost white granular or lump, with a water content of about 60%.

Product characteristics before treatment: semi-solid materials with low viscosity, with a density of about 1.2g/cm³

Requirements after treatment: white paste-like object, uniform and fine,no graininess,solid content 10%~15%, with certain fluidity.

Other Storage tanks we manufactured:

These are normally supplied as tanks on wheels, although tanks with forklift channels can also be supplied. These tanks are fabricated with carbon steel or stainless steel contact parts. Volume from 50L to 10000L.

JINZONG MACHINERY offers stainless steel mixing tanks; stainless steel storage tanks; aboveground tanks (custom, horizontal, vertical); pressure tanks; heat exchangers, etc

Please contact me if you are interested and have any questions

Please contact me if you are interested and have any questions

It has obtained fame and reputation in the market. Its frame is designed to reduce heat transmission.

Our products have gained a remarkable position in the market. Its frame is designed to reduce heat transmission.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy