Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Enamel Reaction Glass Lined Reactor with External Stainless Steel Chemical Reactor Production Line

| Model NO. | JZ-RK | Customized | Customized |

| Condition | New | Warranty | 1 Year |

| After-sales Service | One Year Warranty, Lifelong Maintenance | Trademark | Jinzong Machinery |

| Transport Package | Plwood Case | Specification | Depends on Capactiy |

| Origin | Guangdong, China (Mainland) | HS Code | 8419899090 |

Glass Lined Reactor Enamel Reaction with External Stainless Steel Chemical Reactor Production Line

Glass lined reactor are primarily used for carrying out critical chemical processes where corrosion resistance and chemical inertness are of prime importance. The open type reactors consist of two major parts-the vessel and the over.

The reactors range in capacity from50 liter to 8000 liter. The reactor vessel is provided with all necessary accessories such as agitator, thermowell , etc. Depending on the design pressure requirement, seal may be stuffing box type, single mechanical seal or double mechanical seal.

All types of agitators may be used with these reactors. The reactors can be customized for GMP applications for use in pharmaceutical industry.

They are designed to withstand temperatures between-20ºC to +200ºC and pressure up to 6 Bar in the vessel as well as the jacket. Hence, they provide the benefit of chemical inertness, corrosion resistance and mechanical strength all together to become the preferred MOC for reactor vessels in critical conditions.

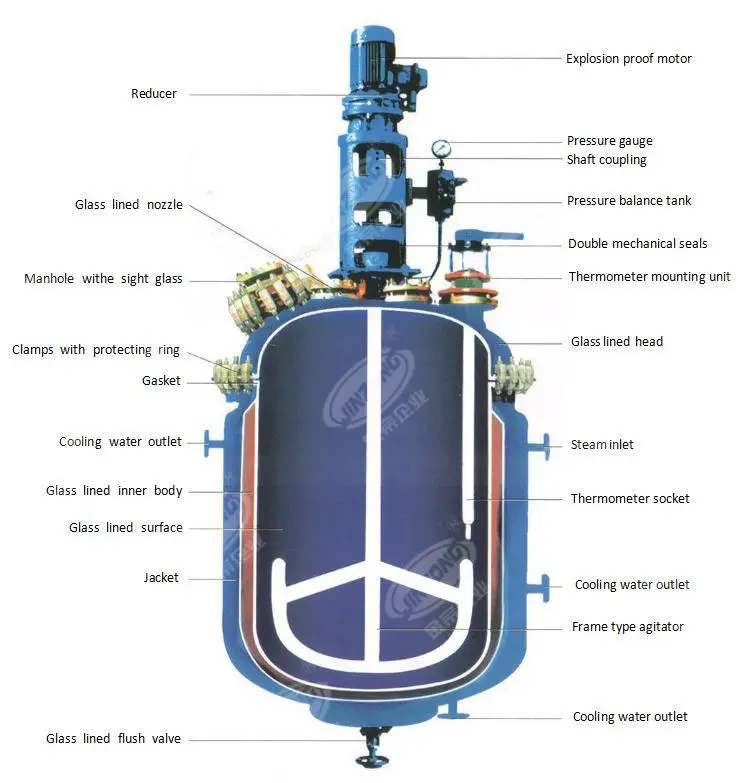

2. Breakdown Drawing:

The glass lined reactor consists of the lid, drum shell, jacket, agitator, shaft seal drive device and support, and the shaft seal drive device is divided into the packing seal and mechanical seal. Corrosion resistance glass lined reactor.

Glass lined reactor are primarily used for carrying out critical chemical processes where corrosion resistance and chemical inertness are of prime importance. The open type reactors consist of two major parts-the vessel and the over.

The reactors range in capacity from 50L to 12500L. The reactor vessel is provided with all necessary accessories such as agitator, thermowell, etc. Depending on the design pressure requirement, seal may be stuffing box type, single mechanical seal or double mechanical seal.

All types of agitators may be used with these reactors. The reactors can be customized for GMP applications for use in pharmaceutical industry.

They are designed to withstand temperatures between-20ºC to +200ºC and pressure up to 6 Bar in the vessel as well as the jacket. Hence, they provide the benefit of chemical inertness, corrosion resistance and mechanical strength all together to become the preferred MOC for reactor vessels in critical conditions.

3. Applications:

The enamel reaction kettle is widely used for reaction, evaporation, conectration, synthesization, polymerization, mineratization, etc. in chemical industry, medecine, dye, pesticide, organic synthesis, petroleum,food additives, industry of national defense and scientific reserch. Our company is an enterprise specialized in designing and manufacturing reaction kettles, we can design and manufacture various types of reaction kettles for users.

Glass line reactor is widely used in Active Pharmaceutical Ingredients API manufacturing process, Intermediate manufacturing process, such as Synthesis reaction, Hydrolysis reaction, quenching reaction, distillation concentration.

Preparations, injections, APIs, Drugs.

Polysaccharide cellulose hemostatic isolation repair glue, hyaluronic acid dressing, collagen dressing, hypochlorite disinfectant

API, sub packed powder injection, lyophilized powder injection, cephalosporin solid, tablet, capsule, granule, small volume injection

Microcrystalline cellulose TC, TF, Tl, TLF, TP, TM, TMS, TMT, top series

Vitamin tablets, vitamin C pills, vitamin E, vitamin B, vitamin; auxohormome; nutramin

Veterinary biological products, veterinary pharmaceutical preparations and feed additives

Soft capsules, analgesic and anti-inflammatory, cardio cerebrovascular, oral cephalic blisters, brain tumor drugs, cephalic blisters for injection

Anti allergic drugs, circulatory system drugs, hormones and endocrine regulating drugs, antipyretic analgesic and non steroidal anti-inflammatory drugs, digestive system drugs, anti-tumor drugs, cervical cancer inhibitors, anticoagulants, vasodilators, antiplatelet aggregators, immunopotentiators

Fang shanneng, ademetionine p-toluenesulfonate, N-acetylneuraminic acid, cytidine disodium triphosphate, citicoline

Citicoline sodium, poly cytidine acid, creatine phosphate sodium, adenosine triphosphate disodium, poly inosinic acid, reduced glutathione, adenosylmethionine succinate

Research and development of cardiovascular, anti-tumor, liver protection, antibiotics, digestive and hemostatic drugs

Pediatric medicine, cardiovascular medicine, anesthesia, severe medicine and chronic disease medicine

4. Technical Information:

| Volume(L) | 50 | 100 | 200 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 5000(B) | 5000(A) | 6300 |

| Motor Power(Kw) | 0.8 | 0.8 | 1.1 | 3 | 3 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 | 7.5 |

| Calculated Volume(L) | 71 | 128 | 247 | 389 | 588 | 1250 | 1720 | 2160 | 3715 | 5650 | 5650 | 7000 |

| Heat Exchange Area | 0.34 | 0.66 | 1.26 | 1.75 | 2.64 | 4.54 | 5.34 | 7.02 | 8.61 | 13.8 | 13.8 | 16.4 |

| N. weight(kg) | 477 | 548 | 706 | 975 | 1052 | 1657 | 2051 | 2170 | 3833 | 4142 | 5032 | 5978 |

Averbatan intermediate manufacturing plant

Hydrolysis of silkworm chrysalis production line

Extraction of complex amino acids from protein production line

MCC Microcrystalline cellulose manufacturing plant

Diaminobutyric acid manufacturing plant

Vitamin derivatives manufacturing plant

Notes:

1) According to user's different requirements,there are many mixing methods(anchor, paddle, pan wheel, push, or box-type stirring )to choose.

2) There are five kinds of heating way,including the jacket heating , coil heating, electric heating,steam heating,and the heat transfer oil heating.

3)The user can choose the explosion-proof device,the sealing device, positive pressure or negative pressure inside the reactor.

4)With many years' experiences of design and production, our technical engineers can design according to the users' special requests.

Why us?

1. Experienced workforce: more than 17 years

2. Excellent quality range of industrial process equipment ,80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider

3. Strict quality controls

4. Good reputation in industry.

5. Customized packaging

6. Simple ordering process

7. Easy payment modes

8. Prompt delivery

9. Have a Professional after-sales service engineering team

Please contact me if you are interested and have any questions

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)