Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Anchor Beating Tank Dispersion Kettle Mixing Tank for Food & Pharmaceutical

| Customized | Customized | Condition | New |

| Warranty | 1 Year | After-sales Service | One Year Warranty, Lifelong Maintenance |

| Trademark | Jinzong Machinery | Transport Package | Plywood Case |

| Specification | Depends on Capactiy | Origin | Guangdong, China (Mainland) |

| HS Code | 8479820090 |

Applications:

1. Resin: Polyurethane resin, Polyester resin, Alkyd resin, Unsaturated polyester resin, Saturated reisn, Acrylic resin, Phenolic resin, Urea-formaldehyde resin, Epoxy resin, Amino resin, etc.

2. Paint: White latex, Water based paint, Oil based paint, Curing agent (hardener), Thinner, etc.

3. Glue: Acrylic emulsion glue, Urea-formaldehyde glue, Epoxy potting glue, Polyurethane sealant/ adhesive, Water based polyurethane, Liquid nails (Free-nail glue), etc.

4. Silicone oil: Silicone oil, Scrap silicone cracking for silicone oil, etc.

2. Model Selection Reference Of Reactor with jacket electric heating 500 litres

| Specification(L) | 10~10000 |

| Design Pressure(Mpa) | Atmospheric or under pressure |

| Material | Carbon steel, stainless steel, enamel, graphite |

| Heating Forms | Electrical heating with medium in jacket, external half-pipe coil steam heating, external half-pipe conduction oil heating, hot water infrared heating. |

| Cooling Forms | Refrigeration medium in the internal pipe coil or jacket |

| Blending Power | Model selection is made according to material viscosity, liquid-solid ratio, liquid specific gravity, solid specific gravity, solid granularity, rotation speed, paddle type, with or without baffle or internal coil. |

| Stirring Blade Forms | Anchor type, frame type, flat paddle type, pitched paddle type, ribbon type, turbo type, pusher type and multiple compound type. |

| Seal | Mechanical seal or stuff packing seal |

| Inner Surface Treatment | polished or no polished |

| Discharge Valve | Flanged ball valve open downward discharge valve and others |

| Technological Pipe Hole | Manhole, sight glass, distillation hole, feed material hole, pressure gauge hole, temp. hole, etc. According to the process requirements increase or decrease |

3. Techincal Parameters Of Reactor with jacket electric heating 500 litres

| Type | 50L | 100L | 200L | 300L | 500L | 1000L | 1500L | 2000L | 3000L | 4000L | 5000L |

| Cylinder Size(mm) | 450×500 | 450×500 | 600×700 | 750×750 | 900×800 | 1200×1000 | 1300×1200 | 1400×1500 | 1600×1500 | 1700×1800 | 1800×2000 |

| Actual Capacity(L) | 61 | 150 | 253 | 396 | 699 | 1393 | 2166 | 3000 | 4066 | 5400 | 6600 |

| Jacket Capacity(L) | 65 | 120 | 200 | 250 | 290 | 560 | 617 | 750 | 1015 | 1226 | 1440 |

| Heating Area() | 0.78 | 1.36 | 1.9 | 2.41 | 2.7 | 4.5 | 5.9 | 7 | 9 | 11 | 12.8 |

| Motor Power(kw) | 0.55 | 1.1 | 1.5 | 3 | 2.2 | 4 | 5.5 | 5.5 | 7.5 | 11 | 11 |

| Rotating Speed(r/min) | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 85 | 63 | 63 | 63 |

| Discharg ing Valve | DN25 | DN25 | DN40 | DN40 | DN50 | DN50 | DN50 | DN65 | DN65 | DN80 | DN80 |

4. Pictures Of Reactor with jacket electric heating 500 litres

Agitator types

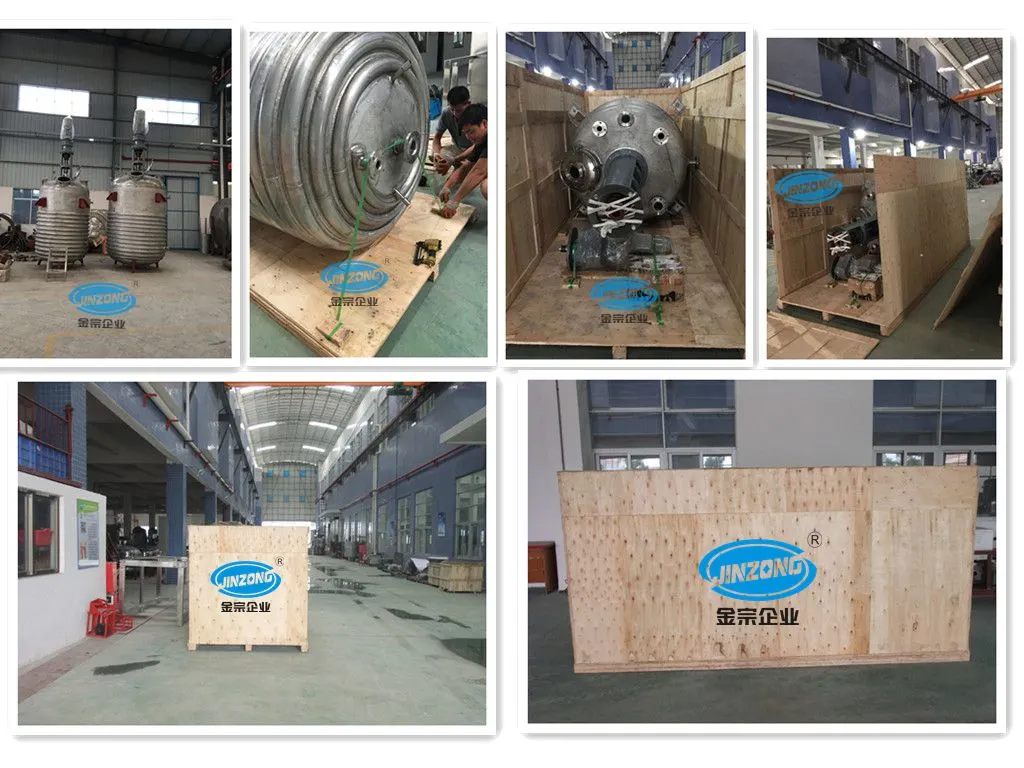

5. Packaging& Shipping

1> Outer packing: plywood case

2> Inner packing: PE film wrapping overall

FOB port: Guangzhou or Shenzhen

6. Our Service

Pre-sales service:

1> Engineering design

2> Equipment model selection guide

3> equipment machinig

After-sales service:

1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.

2> Provide professional after-sales service engineers to abroad installation and debugging.

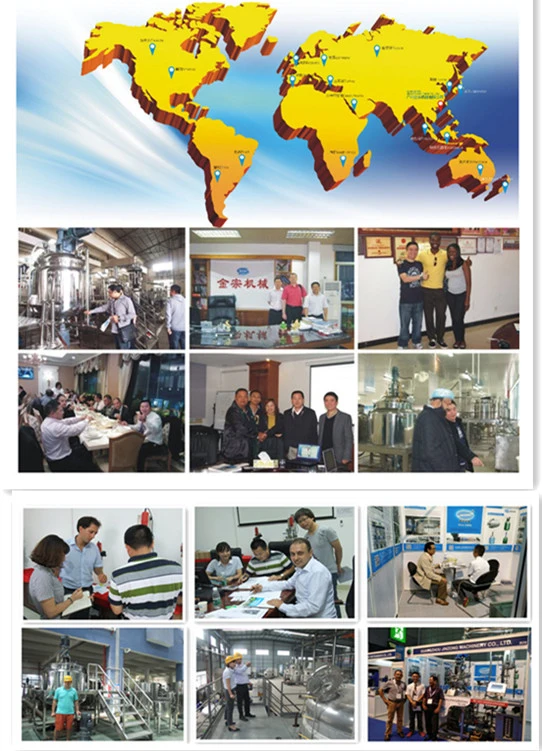

7. Company Information

We are a professional manufacturer of cosmetic,chemical& pharmaceutical machinery and equipment more than 17 years .Product lines range from:

1> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, filling machine etc.

2> Chemical Machinery: reactor, mixing equipment,separation equipment, storage tank etc.

3> Pharmaceutical Machinery: vacuum ointment machine,sanitary stainless reaction pot,alcohol deposition can, collocation tank etc.

8. Why Choose Jinzong Machiney?

1. More than 17 years in Cosmetic and cheimical industry

2. Quality, 80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider

3. Good reputation in industry.

4.Have a Professional after-sales service engineering team

5.Large scale and strong strength

9. Certificates:

10. Customers:

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)