Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

2000 Liter Vacuum Emulsifier for Ointment

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

| Customized | Customized | Condition | New |

| Warranty | 1 Year | After-sales Service | One Year Warranty, Lifelong Maintenance |

| Trademark | Jinzong Machinery | Transport Package | Plywood Case |

| Specification | Depends on Capactiy | Origin | Guangdong, China (Mainland) |

| HS Code | 8419899090 |

2000 Liter Vacuum Emulsifier for Ointment

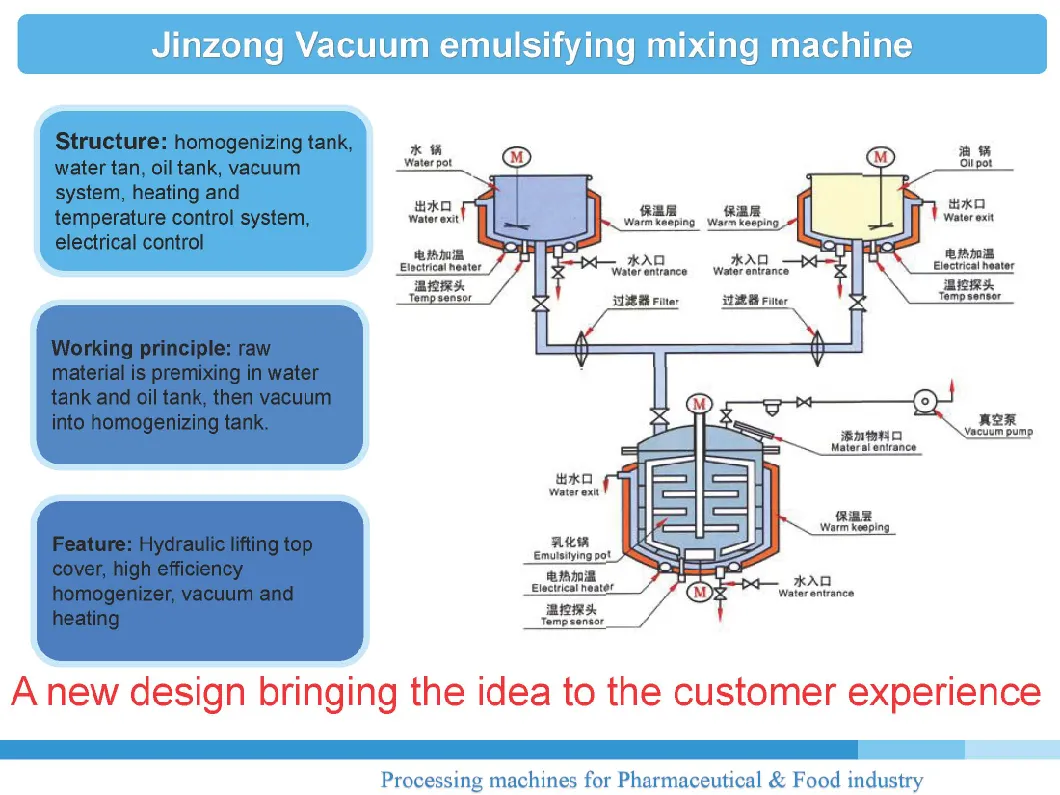

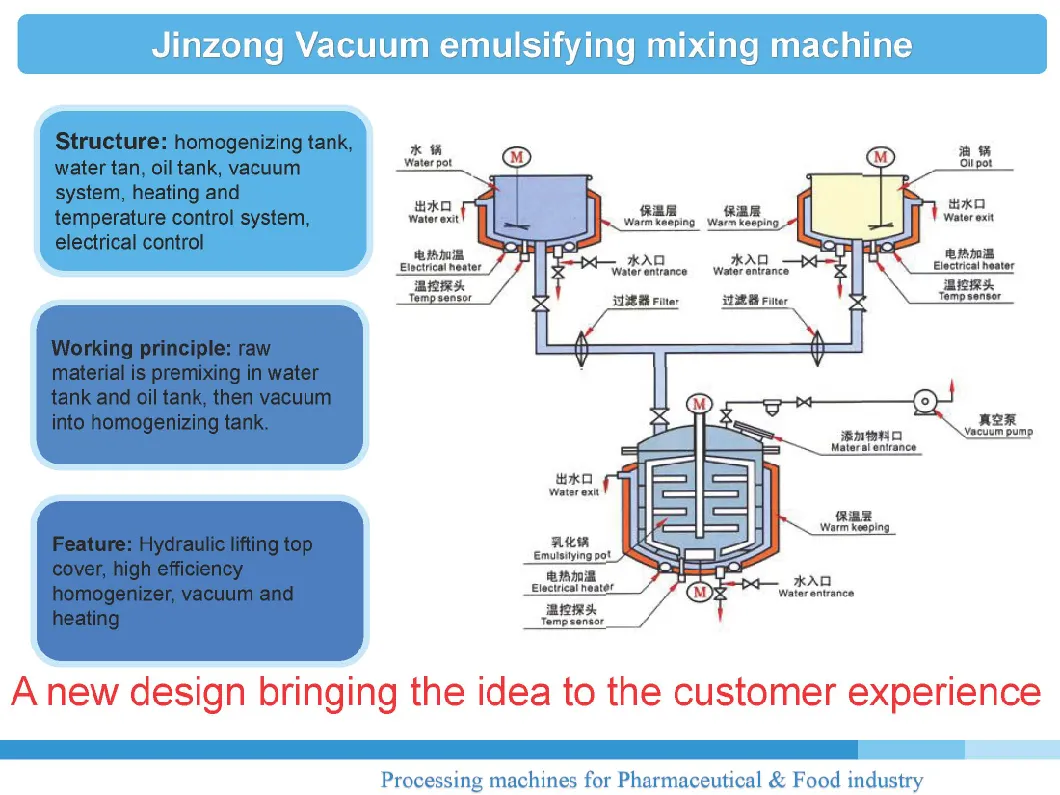

Jinzong vacuum emulsifying mixer is the most popular vacuum emulsifier homogenizer design in Asia and is suitable for making small to medium batches of ointment, cream and emulsions.

Vacuum homogenizing emulsifying mixer project:

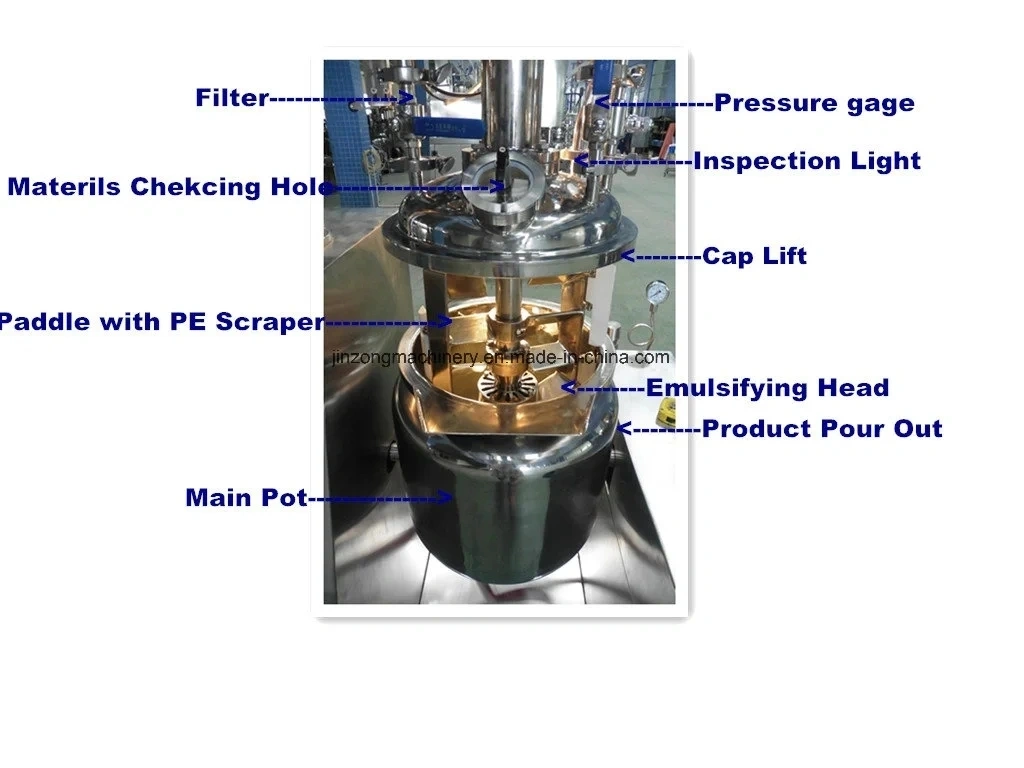

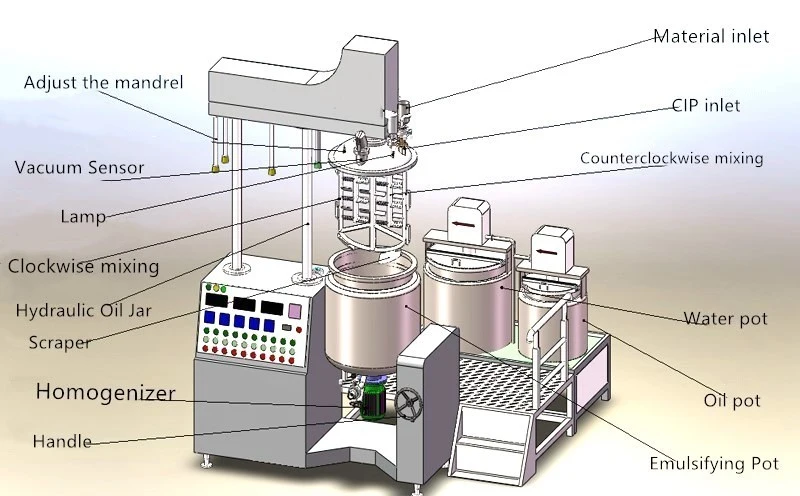

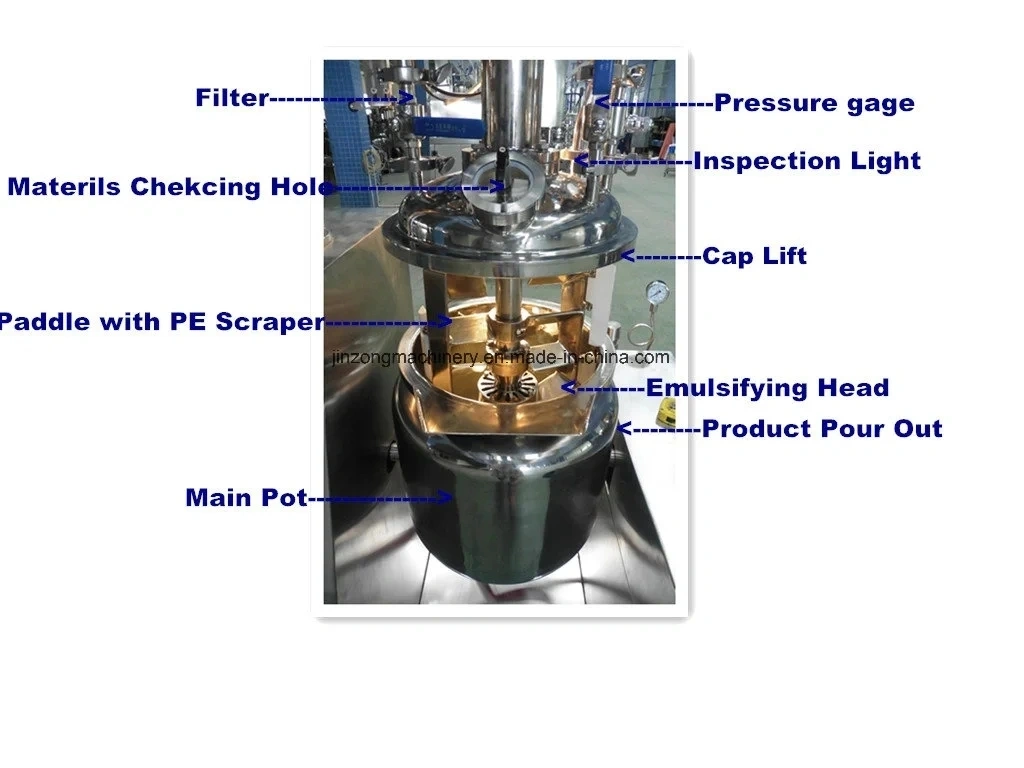

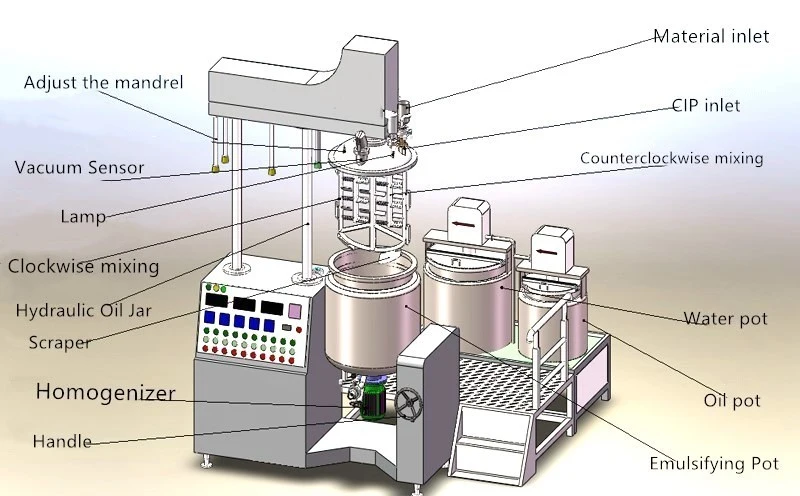

Mixing consists of vacuum homogeneous emulsifying machine, heating system, mixing system, vacuum system, electric lifting system, operation control cabinet, piping system.

Product Function Brief:

Product Function Brief:

Stainless steel: SUS316L

Adopt hydraulic lift cover

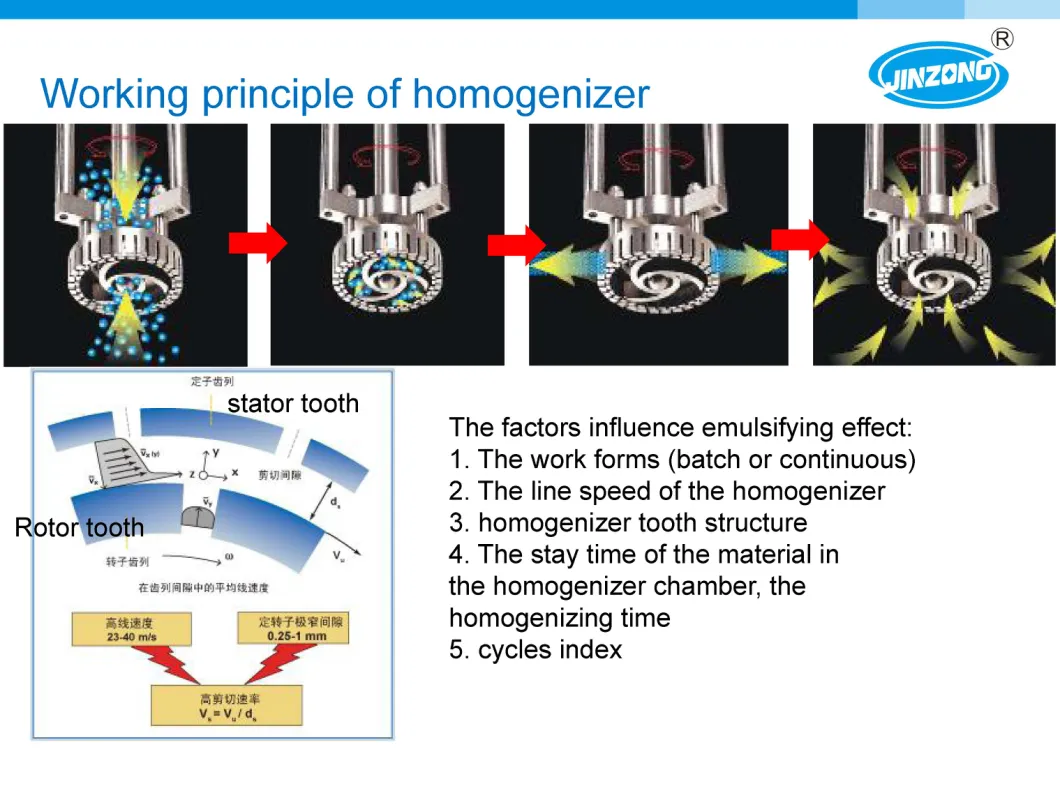

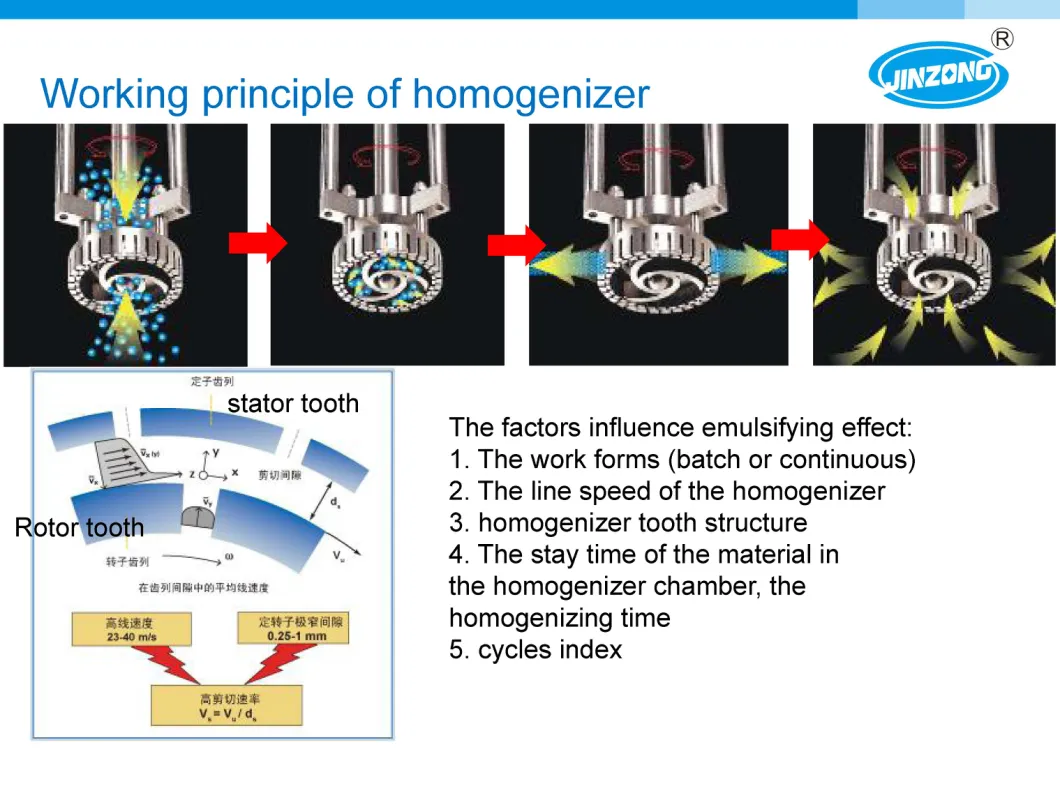

High-speed homogenizing blender(speed from 0-3000RPM, frequency speed regulation)

Scraper blender speed: 0-83 RPM.

The working procedure is operated in the condition of vacuum in order to prevent the material coming into being buble after high-speed blending and reach the request of sanitation and asepsis.

CIP cleanning system is equipped in this system.

The contact part of vessel is made of SUS316L. other parts are made of SUS304.

Mirror finish of the inside surface is 300mesh.

Using SIMENS motor in order to ensure the stabilization of the contral.

Using Panasonic transducer.

Application:

It is the most suitable equipment to produce Mayonnaise, Sandwich Sauce, Salad Dressing, Butterfly, Ketchup, Bread Sauce, chocolate sauce or pudding and other cream products.

Feature:

Working capacity from 1L to 2000L;

Suitable for cream and emulsions of 10,000~50,000cps viscosity;

Internal emulsifying and homogenizing by top mounted batch homogenizer or bottom homogenizer;

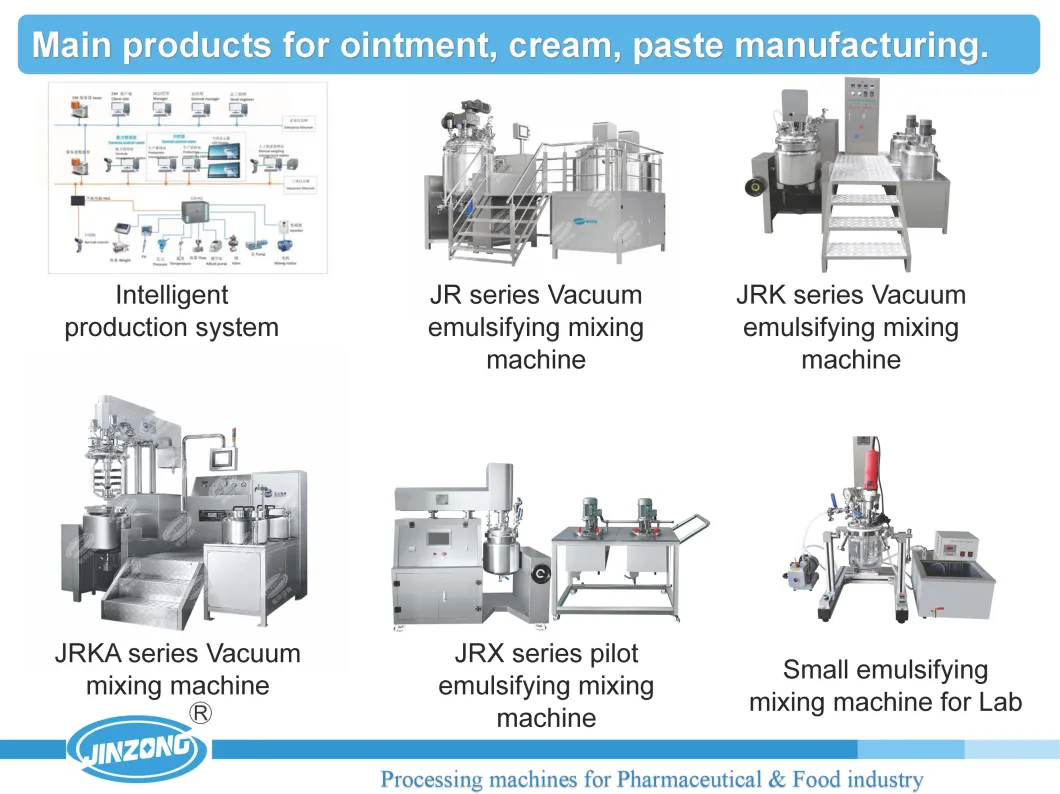

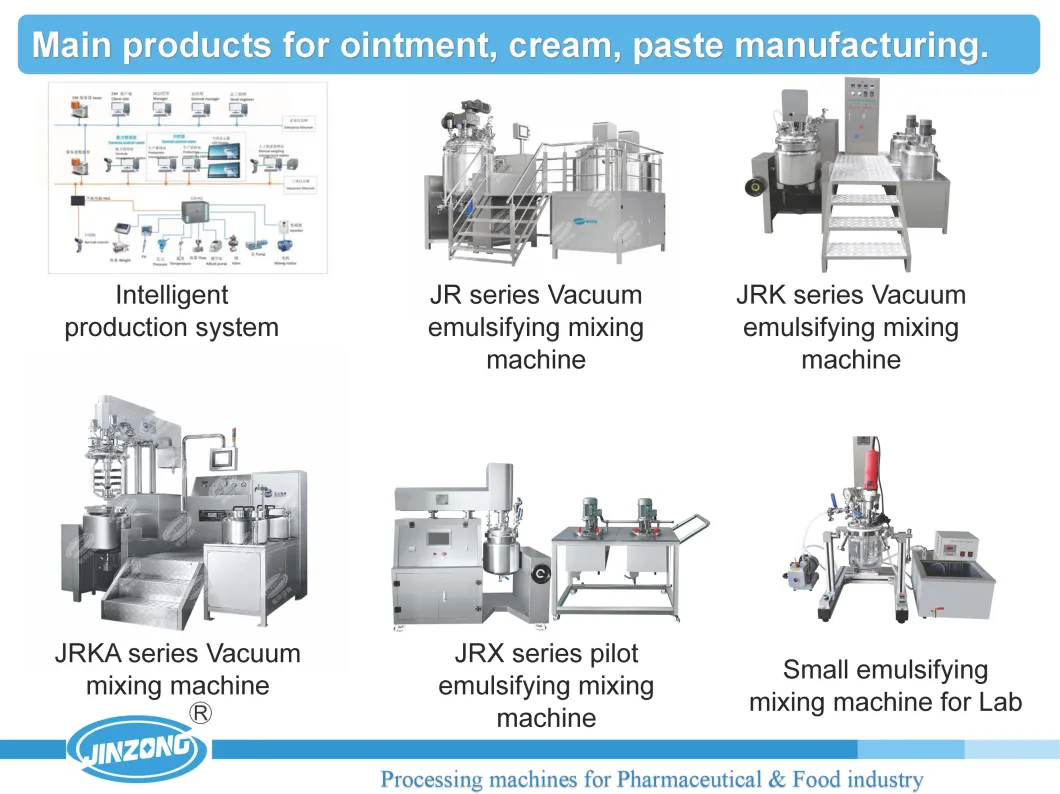

JR series Vacuum emulsifying mixing machine

JRK series Vacuum mixing machine

JRKA series Vacuum mixing machine

JRX series pilot emulsifying mixing machine

REQUEST FREE QUOTE

Contra mixing system of center agitator and wall scraper;

Outer frame agitator has triangle design for enhanced mixing;

Variable speed for homogenizer and agitators;

Oil hydraulic lifting system for easy cleaning and maintenance;

Double jackets for heating and cooling;

Different jacket designs available for steam and electric heating;

Complete process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit;

Double temperature probes and controllers for electrical heating in main emulsification machine;

Vacuum system to take out the air bubbles during mixing and to transfer the ingredients;

Compressed air to discharge the finished cream;

Tilting system for discharging finished product and easy cleaning;

Multiple safety protection devices for vacuum, hydraulic pump and workers;

All contact parts are made of SS316L and mirror polished;

Spray ball is equipped to connect customer's CIP;

The specifications of the vacuum emulsification equipment comply with cGMP regulations;

Push buttons control panel for easy operation;

Power supply of 380V, 50Hz, 3 Phase;

Options

Fixed cover with bolts or welding to save budget;

Frame type slow agitator for oil pre-mixer;

Mettler-Toledo load cells;

Siemens PLC for automation of mixing, dispersing, emulsifying, homogenizing, vacuum, transferring, heating and cooling etc;

Flow meter automation for feeding liquid oil and water;

Pressure vessel design for different steam pressure;

SIP is available upon request;

Different power supply acceptable;

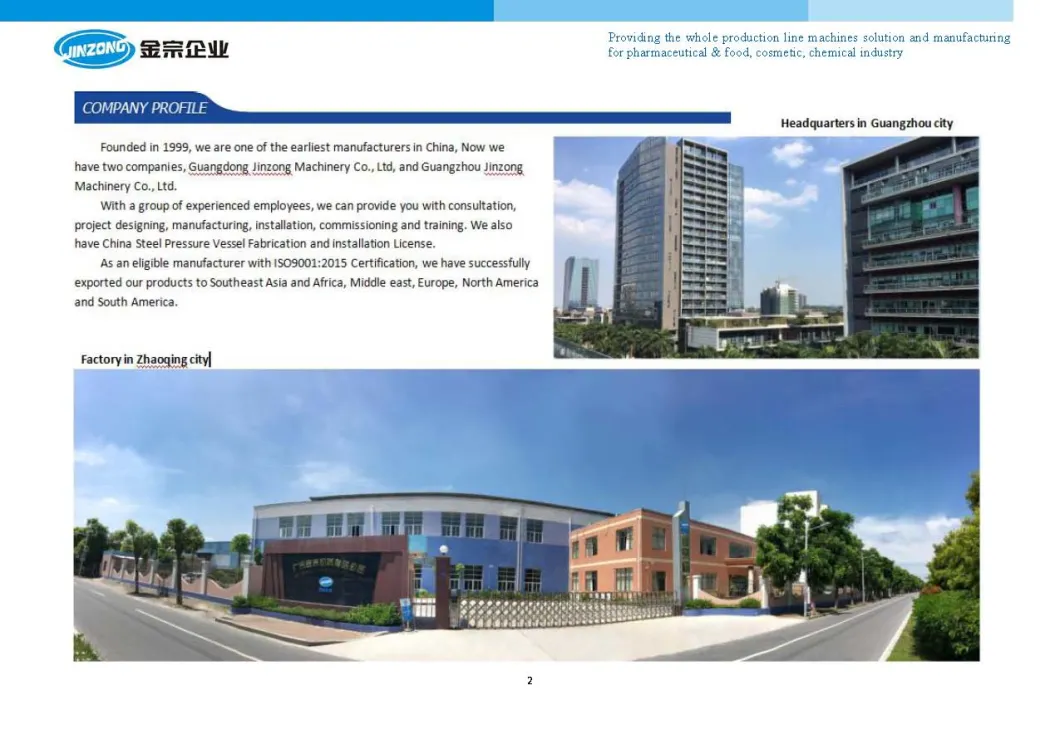

Guangdong Jinzong Machinery Co., Ltd. is a professional manufacturer of chemical, biological & pharmaceutical machinery and equipment more than 20 years .

Please do contact us should you have any inquiries about our product. We are competent and are your one stop shopping centre for all your machinery needs.

Jinzong vacuum emulsifying mixer is the most popular vacuum emulsifier homogenizer design in Asia and is suitable for making small to medium batches of ointment, cream and emulsions.

Vacuum homogenizing emulsifying mixer project:

Mixing consists of vacuum homogeneous emulsifying machine, heating system, mixing system, vacuum system, electric lifting system, operation control cabinet, piping system.

Product Function Brief:

Product Function Brief:Stainless steel: SUS316L

Adopt hydraulic lift cover

High-speed homogenizing blender(speed from 0-3000RPM, frequency speed regulation)

Scraper blender speed: 0-83 RPM.

The working procedure is operated in the condition of vacuum in order to prevent the material coming into being buble after high-speed blending and reach the request of sanitation and asepsis.

CIP cleanning system is equipped in this system.

The contact part of vessel is made of SUS316L. other parts are made of SUS304.

Mirror finish of the inside surface is 300mesh.

Using SIMENS motor in order to ensure the stabilization of the contral.

Using Panasonic transducer.

Application:

It is the most suitable equipment to produce Mayonnaise, Sandwich Sauce, Salad Dressing, Butterfly, Ketchup, Bread Sauce, chocolate sauce or pudding and other cream products.

Feature:

Working capacity from 1L to 2000L;

Suitable for cream and emulsions of 10,000~50,000cps viscosity;

Internal emulsifying and homogenizing by top mounted batch homogenizer or bottom homogenizer;

JR series Vacuum emulsifying mixing machine

| Model | Volume of Main Tank (L) | Volume of Dissolving tank(L) | Dimension(mm) | total power(kw) | weitht(kg) |

| 100 | 130 | 70/100 | 2600*2500*2300 | 5.5 | 1200 |

| 200 | 260 | 120/190 | 2800*3000*2650 | 7.7 | 1600 |

| 300 | 375 | 150/260 | 2900*3000*2750 | 10.5 | 1900 |

| 500 | 620 | 300/460 | 3300*3550*3050 | 15 | 2500 |

| 1000 | 1250 | 620/900 | 4100*3900*3500 | 20.5 | 4000 |

| 2000 | 2600 | 1200/1500 | 4500*5200*4000 | 26 | 6000 |

| 3000 | 3800 | 1500/2400 | 4800*5700*4200 | 33 | 9000 |

| 5000 | 6500 | 2500/3600 | 5100*6400*4800 | 37 | |

| 10000 | 12500 | 5000/7000 | 52 |

JRK series Vacuum mixing machine

| Model | Volume of Main Tank (L) | Volume of Dissolving tank(L) | Dimension(mm) | total power(kw) | weitht(kg) |

| 50 | 75 | 45/65 | 2700*2300*1950-2650 | 9 | 1600 |

| 100 | 130 | 70/100 | 2900*2700*2050-2800 | 10 | 1800 |

| 200 | 260 | 120/190 | 3200*2900*2350-3300 | 13 | 2200 |

| 300 | 375 | 150/260 | 3350*3000*2550-3650 | 17 | 2500 |

| 500 | 620 | 300/460 | 3800*3400*2800-4050 | 25 | 3300 |

| 1000 | 1250 | 620/900 | 4150*4150*3700-5200 | 32 | 5000 |

JRKA series Vacuum mixing machine

| Model | Volume of Main Tank (L) | Volume of Dissolving tank(L) | Dimension(mm) | total power(kw) | weitht(kg) |

| 50 | 75 | 45/65 | 2700*2500*2000-2700 | 9 | 1600 |

| 100 | 130 | 70/100 | 2900*2500*2000-2800 | 10 | 1800 |

| 200 | 260 | 120/190 | 3200*3000*2400-3350 | 13 | 2200 |

| 300 | 375 | 150/260 | 3350*3100*2550-3650 | 17 | 2500 |

| 500 | 620 | 300/460 | 3800*3400*2850-4100 | 25 | 3300 |

| 1000 | 1250 | 620/900 | 4150*4150*3700-5200 | 32 | 5000 |

JRX series pilot emulsifying mixing machine

| Model | Volume of Main Tank (L) | Volume of Dissolving tank(L) | Main Tank Dimension(mm) | Dissolving Tank Dimension(mm) | Total Power (kw) |

| 5L | 1.2 | 3/3 | 1100*400*1250-1600 | 1000x600x800 | 6 |

| 10L | 13 | 6/10 | 1650*600*1800-2350 | 1200x600x800 | 8 |

| 20L | 26 | 12/16 | 1650*600*1800-2400 | 1200x600x800 | 10 |

| 30L | 37 | 18/25 | 1650*600*1800-2400 | 1200x600x800 | 15 |

| 50L | 60 | 30/40 | 1700*650*1900-2500 | 1200x600x900 | 19 |

REQUEST FREE QUOTE

Contra mixing system of center agitator and wall scraper;

Outer frame agitator has triangle design for enhanced mixing;

Variable speed for homogenizer and agitators;

Oil hydraulic lifting system for easy cleaning and maintenance;

Double jackets for heating and cooling;

Different jacket designs available for steam and electric heating;

Complete process of mixing, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit;

Double temperature probes and controllers for electrical heating in main emulsification machine;

Vacuum system to take out the air bubbles during mixing and to transfer the ingredients;

Compressed air to discharge the finished cream;

Tilting system for discharging finished product and easy cleaning;

Multiple safety protection devices for vacuum, hydraulic pump and workers;

All contact parts are made of SS316L and mirror polished;

Spray ball is equipped to connect customer's CIP;

The specifications of the vacuum emulsification equipment comply with cGMP regulations;

Push buttons control panel for easy operation;

Power supply of 380V, 50Hz, 3 Phase;

Options

Fixed cover with bolts or welding to save budget;

Frame type slow agitator for oil pre-mixer;

Mettler-Toledo load cells;

Siemens PLC for automation of mixing, dispersing, emulsifying, homogenizing, vacuum, transferring, heating and cooling etc;

Flow meter automation for feeding liquid oil and water;

Pressure vessel design for different steam pressure;

SIP is available upon request;

Different power supply acceptable;

Guangdong Jinzong Machinery Co., Ltd. is a professional manufacturer of chemical, biological & pharmaceutical machinery and equipment more than 20 years .

Please do contact us should you have any inquiries about our product. We are competent and are your one stop shopping centre for all your machinery needs.

The product increasingly becomes practical and applicable in the industry. The product is easy to install, which greatly save human resources.

The product is comprehensively suitable for applying in the industry. The product is easy to install, which greatly save human resources.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2026 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy