Guangdong Jinzong Machinery Co., Ltd.

Contact Sales at JuJiao.

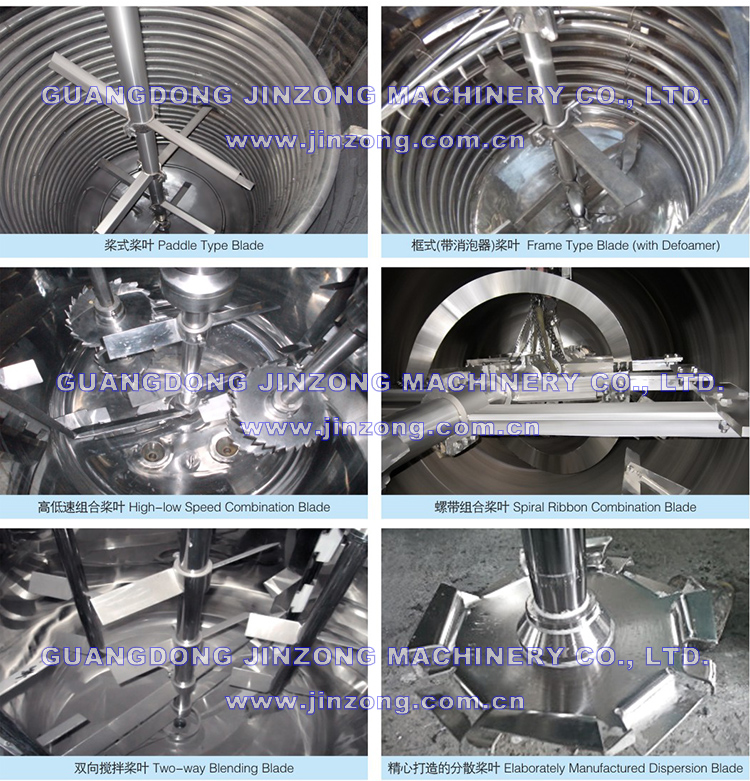

In order to realize the heating, evaporation, cooling and low and high speed mixing reaction required by the process, the reactor is an essential equipment. However, if the maintenance of the reactor is not in place, it often causes safety and environmental pollution accidents, which should be paid attention to in use.

the reactor shall be installed in the operation room meeting the safety requirements for hazardous chemicals production, and each operation room shall be provided with access and outlet to the outside, so as to ensure good ventilation of the equipment.

after opening the package, check whether the equipment is damaged, install the equipment according to the equipment model and structural drawing, and check the equipped parts according to the packing list. Pay attention to the heating and cooling methods and media meet the process requirements, and the installation should meet the relevant safety specifications.

the sealing condition of the chemical reactor is very critical, which directly affects the use effect and production safety, and is also the most important part of the equipment. Therefore, it is necessary to pay attention to check the sealing parts according to the operation manual, and keep the lubrication or cooling medium to meet the requirements. Once the leakage is found, stop the machine immediately for inspection and maintenance, and then put it into use again after passing the pressure maintaining test without leakage.

at ordinary times, it is necessary to pay attention to the cleaning of measuring parts such as instruments and sensors, maintain the sensitivity of sensors, and carry out regular calibration and verification according to the specification requirements, conduct fastening inspection on the contact parts of connecting lines, and conduct regular inspection on the integrity of shielding devices.

pay attention to the action sensitivity of each process valve to ensure the normal operation of valve actuator and avoid blockage. Once any abnormality is found, it is recommended to replace it.

observe the operation at any time, stop the machine for inspection in case of abnormal noise or vibration, pay special attention to the lubrication and temperature rise of each bearing point, inform the supplier for inspection and treatment in case of abnormality, and replace the lubricating oil regularly and tighten the connecting bolts at any time. It can also make early warning by online monitoring system load change through jinzong Internet of things system.

ensure the use of safety devices in accordance with safety regulations, and strictly control the phenomenon of blockage and failure. Regular inspection to relevant departments.

ensure stable power supply, normal signal feedback and sensitive action of actuator. Do a good job in lightning protection, surge protection and electrostatic interference prevention measures, do not plug in and out various modules at will, pay attention to the optical brazing and other signal lines, do not be suppressed and interfered by other process pipelines and power cables, such as WiFi signal transmission, you are welcome to check the signal source and transmission quality frequently.

after each use, the reaction kettle body shall be cleaned, the process pipeline shall be emptied, and the relevant filtering devices shall be cleaned. If the anti-corrosion conditions are involved, the cleaning and protection shall be done in time according to the anti-corrosion requirements. When it is put into use again, it is necessary to conduct a comprehensive inspection of the system and equipment, and the trial run can be put into production only after the normal operation.

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist