Guangdong Jinzong Machinery Co., Ltd.

Contact Sales at JuJiao.

Working principle:

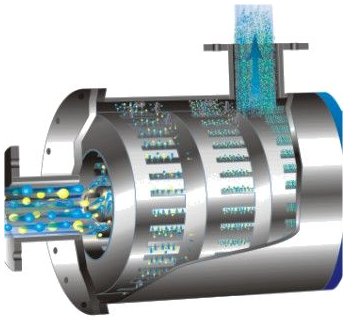

By utilizing the high-speed rotation of a special rotor in the stator cavity to generate a vacuum, a fluid containing multiple phases is continuously and rapidly sucked into the shear cavity, efficiently, quickly, and uniformly distributing one or more phases into another continuous phase (while in general, the phases are immiscible), which is commonly known as homogeneous emulsification. During operation, due to the extremely high linear speed and high-frequency mechanical effects generated by the high-speed rotation of the rotor, the material is subjected to strong hydraulic shear, liquid layer friction, centrifugal compression, impact tearing, and turbulence in the precise gap between the stator and rotor. This can efficiently, uniformly, and quickly distribute one or more phases to another continuous phase, allowing insoluble solid, liquid, and gas phases to emulsify and disperse uniformly and finely under the action of corresponding mature processes and appropriate additives. After high-frequency cycling, stable and high-quality products are ultimately obtained.

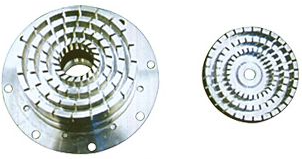

Common structures:

There are many structural forms of emulsifiers (homogenizing heads), and the most common ones are as follows:

High shear dispersion type (runoff type)

Pipeline type (Runoff type)

Cone mill type (Axial flow type)

(Axial flow type)

(Axial flow type)

Efficient (Runoff type)

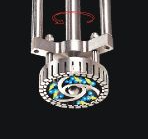

There are various structural forms of emulsifiers, but the basic working principles of each type are roughly the same. We can illustrate this through the working schematic diagram of the most traditional and simple high shear dispersion (radial) emulsifier:

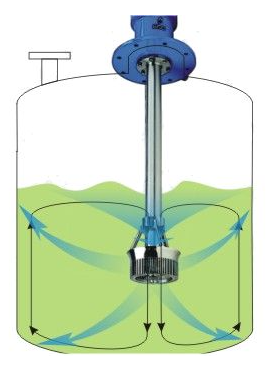

Process diagram:

The development of high shear mixing emulsification technology has formed a new discipline that is different from traditional stirring, and it is constantly expanding its application fields and technological updates. It is praised by users as the "industrial revolution of mixers"; The core structure of a high shear mixing emulsifier is the stator and rotor system, which has two structural forms: a claw type structure suitable for suspended materials with higher specific gravity and a blade structure suitable for materials with higher specific gravity and easier sedimentation.

Work principle breakdown:

Under the centrifugal force generated by the high-speed rotating rotor, the material in the figure is simultaneously sucked into the working chamber axially from the upper and lower feeding areas of the working head.

The strong centrifugal force separates the material from the narrow and precise gap between the radial swing and rotor, while also being subjected to centrifugal compression, impact and other forces, causing the material to initially disperse and emulsify.

At the outer end of the high-speed rotating rotor, a linear velocity of at least 15m/s is generated, with a maximum of 50m/s, and strong mechanical and hydraulic shear, liquid layer friction, impact tearing are formed, allowing the material to be fully dispersed, emulsified, homogenized, crushed, and shot out through the stator slot, continuously and rapidly from the radial direction.

Under the resistance of the material itself and the container wall, the flow direction is changed. At the same time, under the action of the axial suction force generated in the rotor area, strong turbulence is formed in the upper and lower directions. The material undergoes several cycles and finally completes the dispersion, emulsification, and homogenization process.

By explaining the process diagram above, I believe everyone has a preliminary understanding of homogeneous emulsification. I hope it can be helpful to you.

Jinzong Enterprise has been focusing on the design and manufacturing of food and pharmaceutical machinery and equipment, research and development of intelligent control systems, engineering design and installation for more than 20 years. It has a design and marketing service center in Guangzhou and two production factories in Zhaoqing National High tech Zone. It has the qualifications for special equipment pressure vessel manufacturing and pressure pipeline installation (GC2). It is a national high-tech enterprise, a provincial-level specialized and innovative enterprise, with two provincial-level famous brand products, dozens of product patents, software copyrights, and provincial-level high-tech products. It has passed the national intellectual property standard certification, ISO9001-2015 international quality system certification, and EU CE certification, and has been rated as a "Guangdong Province Contract abiding and Creditworthy Enterprise" by the Guangdong Provincial Administration for Industry and Commerce for many consecutive years. Its users are distributed in more than 50 countries and regions around the world. Received widespread recognition and support from over 2000 enterprises of all sizes at home and abroad.

To do a good job, one must first sharpen their tools. Jinzong Enterprise upholds the concept of "Quality is Like Gold, Craftsmanship is the Core", and provides advanced and automated production lines to manufacturing factories. Friends from home and abroad are welcome to visit and guide us!

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist