*Outline:

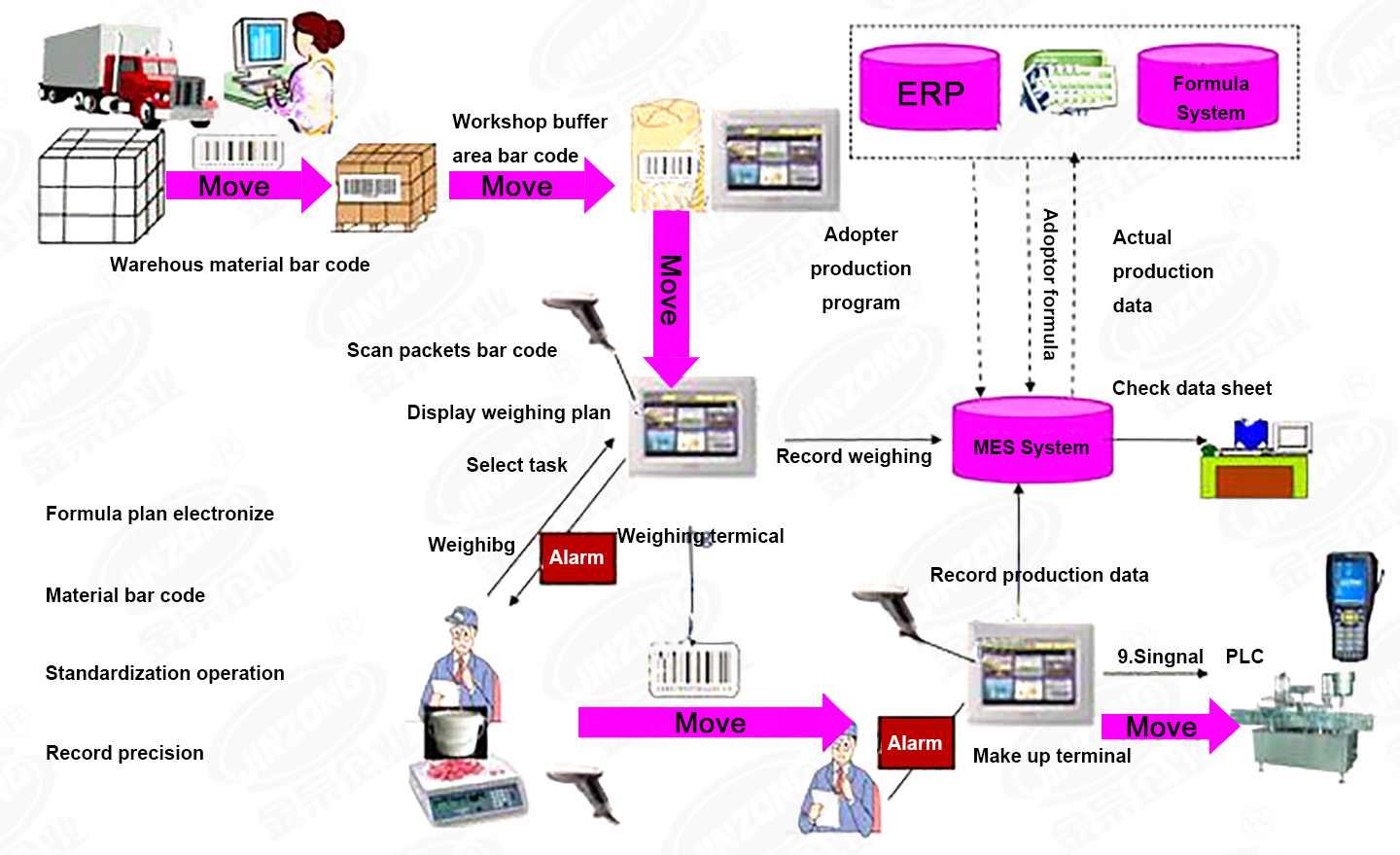

Weighing is the key to the entire production process of the coating, and it is also a difficult point for the coating company to eliminate potential risks and improve efficiency. Thank to years of project experience in the coatings industry, we have developed a weighing and batching system to reduce product failure rate and ensure data integrity and traceability of the production process.

*System benefits:

Provide efficiency: make information flow more efficient. Make the production process more fluid.

Compliance: Through communication, full automatic electronic records systems and equipment, better production process to ensure compliance.

Visibility: more convenient to check real-time production, so that managers with new ways to manage the production process, strategizing.

◪ Electronic prescription

Ensure strict implementation of staff weighed weighing operation in accordance with the prescription , prevent the final product quality deviations caused by the weighing errors, resulting in higher production costs.

◪ Online precise weighting

According to the work order has been issued and visible weighting tasks can be pre-prepared material, improve the material pulling efficiency.

Graphical weight electronic instructions, and efficient process control, the operating system guide personnel stop by step to complete the prescription weight, so that the weighing process is simple, fast and accurate.

Scales with management, automatically determine when the weighting scale is in a calibrated state.

Weighing review materials before scanning, automatic batch determination is qualified, to avoid the risk of expired materials.

◪ Automatically generated weighing record

Allow producers to concentrate weighing operation, the system automatically records the weighing data. Late prevent artificial statistical errors.

◪ Mobile feeding

Automatic review before feeding, to prevent the risk of material mixed batch. Feeding becomes more controllable, simple.

◪ Mobile Terminal Report

Management anytime, anywhere through mobile terminals, check real-time production schedules, Production anomalies, view production report.

◪ Full traceability

The system automatically records the weighing and feeding process data in the production process, providing production record and audit trail data, make retroactive become faster.

◪ Full production material bar code scanning

All materials throughout the bar code identification, weighing and feeding when scanning a key, to prevent the material difference wrong, to avoid the risk of manual identification.

◪ Scalable system architecture

Weighing system can be done with ERP, dosing system, warehouse management system and other systems connectivity, automatic data collection.

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist