*Mayonnaise Mixing tank with inline homogenizer Machine:

Mayonnaise processing plant is a continuous production plant for manufacturing of mayonnaise and other emulsion foods encompassing advanced technologies.

This is a fully automated system comprising of mixing tanks and buffer tanks that are highly compact. Despite this, the design allows cleaning and maintenance at ease. The complete plant design approach is modernistic and state of art technology promises reduced cost.

Material: SS316L

Design Pressure:-1 -10 Bar (g) or ATM

Work Temperature:0-200 °C

Volumes:5~30000L, customized

If you have any technical requirement,feel free let us know . We can design the tanks according to your requirement .

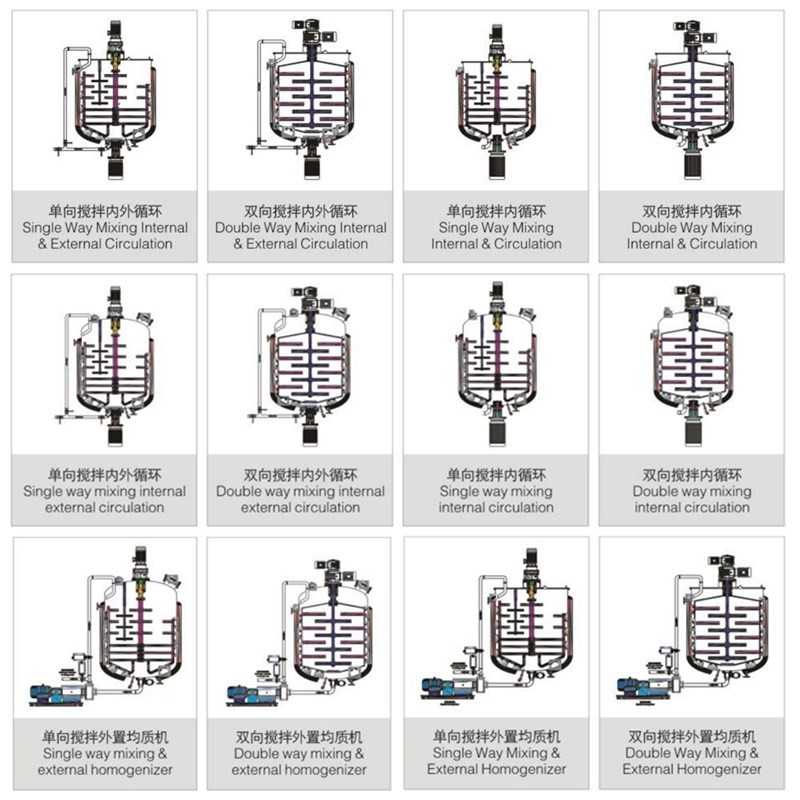

*MAIN COMPOSITION of stainless steel jacket mixing tank:

Stainless steel jacket mixing tank is mainly composed of tank body, mixing system and accessories. The tank body includes inner cylinder, outer cylinder, jacket and supporting foot, etc. Rock wool filling is used as insulation layer between inner cylinder and outer cylinder if needed, jacket form is integrate jacket.

The accessories mainly include sanitary manhole, mirror, light, material and liquid inlet and outlet pipe, thermometer, pressure gauge or customized.

*Stainless steel jacket mixing tank performances and features:

◪ Design compliance with cGMP.

◪ Agitator is on top frame type with scrapper;

◪ Atmospheric, Vacuum or Pressure Operation;

The sugar crystals and water are added to the sugar melting vessel. The steam is supplied and the sugar crystals are melted. Addition of additives manually and it mixes at the set temperature.

The meltdown sugar is transferred to manufacturing vessel after filtration in cone filter through transfer pump. The steam and heat are supplied in manufacturing vessel and the additives are added manually and mixed at the set temperature.

Then the homogenizer performs emulsification and dispersion.

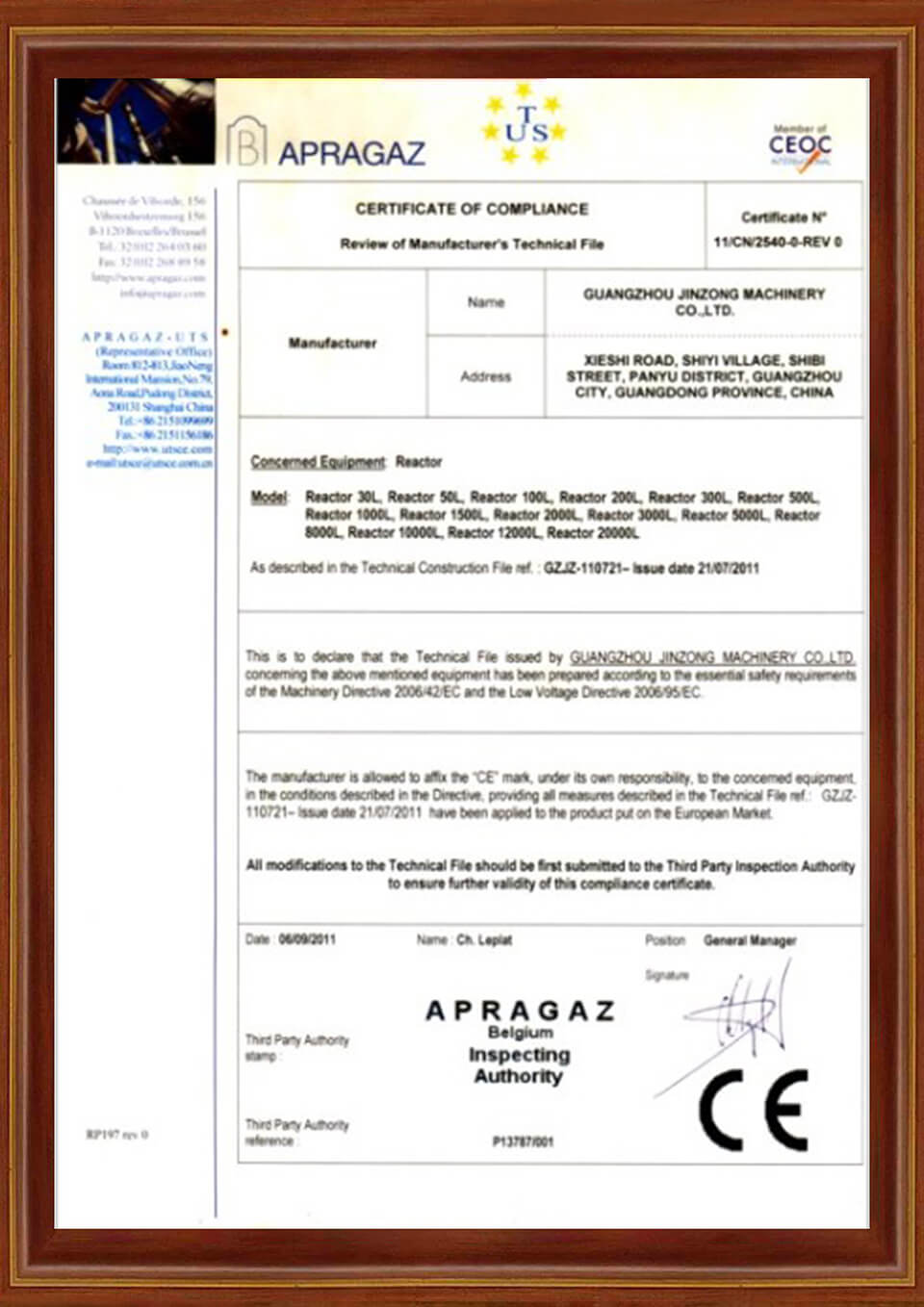

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist