Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery wholesale gl reactor company for reaction

| Customized | Customized | Condition | New |

| Warranty | 1 Year | After-sales Service | One Year Warranty, Lifelong Maintenance |

| Trademark | Jinzong Machinery | Transport Package | Plywood Case |

| Specification | Depends on Capactiy | Origin | Guangdong, China (Mainland) |

| HS Code | 8419899090 |

Active Pharmaceutical Ingredients Chemical Synthesis Reactor for Lab Pilot Production

This equipment is including: Reaction vessel, mixing system, vacuum system, condenser, separator, conduction oil preheating system, platform

1.Capacity 5L-200L.

2.Including jacketed reactor,condenser,storage tank,conduction oil preheating tank,hot oil pump,pipelines,valves,temperature gauge PT100,pressure gauge,platform etc.

3.Made of SUS316L and SUS304.

4.Heating and cooling by jacket or heated by jacket and cooling by inner pipe coil

This equipment is including: Reaction vessel, mixing system, vacuum system, condenser, separator, conduction oil preheating system, platform

1.Capacity 5L-200L.

2.Including jacketed reactor,condenser,storage tank,conduction oil preheating tank,hot oil pump,pipelines,valves,temperature gauge PT100,pressure gauge,platform etc.

3.Made of SUS316L and SUS304.

4.Heating and cooling by jacket or heated by jacket and cooling by inner pipe coil

*Jinzong Machinery provides a full range of testing and pilot unit services for :

Reformulation of products

Development of new resins and polymer emulsions

Optimization of reactor design

Optimization of process and product quality

Jinzong Machinery also supplies skid mounted pilot units for installation at the client's site. The custom designed product reactors range in size from 10 liters to 1000 liters.

Product Detailed Pictures

*Model selection reference of reaction kettle

| Composition | Instructions |

| Specification (L) | 5-200 |

| Design Pressure (Mpa) | Atmospheric Pressure or under pressure |

| Material | Carbon steel, stainless steel, enamel, graphite |

| Heating Forms | Electrical heating with medium in jacket, external half coil steam heating, external half conduction oil heating, hot water infrared heating etc. |

| Cooling Forms | Refrigeration medium in the internal pipe jacket |

| Blending Power | Model selection is made according to material viscosity, liquid-solid ratio, liquid specific gravity, solid specific gravity, solid granularity, rotation speed, paddle type, with or without baffle or internal coil. |

| Stirring blade Forms | Anchor type, frame type, flat paddle type, pitched paddle type, ribbon type, turbo type, pusher type and multiple compound type |

| Seal | Mechanical seal or stuff packing seal |

| Inner Surface Treatment | Polished or no polished |

| Discharge Valve | Flanged ball valve, open downward discharge valve and others |

| Technological Pipe Hole | Manhole, sight glass, distillation mouth, imported materials, pressure gauge port, temperature, mouth, mouth filling N2, |

Model Parameter | Reactor Volume(L) | Mixing speed (rpm) | Heat exchange surface (m2) | Separator(L) | Total power(including heating power)(KW) |

| JZ-10 | 10 | 0-84 | 0.5 | 5 | 6.37 |

| JZ-30 | 30 | 0.5 | 12 | 12.37 | |

| JZ-50 | 50 | 1 | 15 | 18.55 | |

| JZ-100 | 100 | 2 | 25 | 19.65 | |

| JZ-150 | 150 | 2.5 | 30 | 26.2 | |

| JZ-200 | 200 | 3 | 50 | 33.5 | |

| Note: In case of inconformity of the data in the table due to technical improvement or customization, the real object shall prevail. This equipment is including: Reaction vessel, mixing system, vacuum system, condenser, separator, conduction oil preheating system, platform. 1. Heating and cooling method: 1. Heating and cooling by jacket. 2. Heating by jacket and cooling by inner pipe coil. 2. Type of electrical device: 1. Ex-proof type. 2. Normal type 3. Electric cabinet control mode: 1. Touch-screen control. 2. Button control | |||||

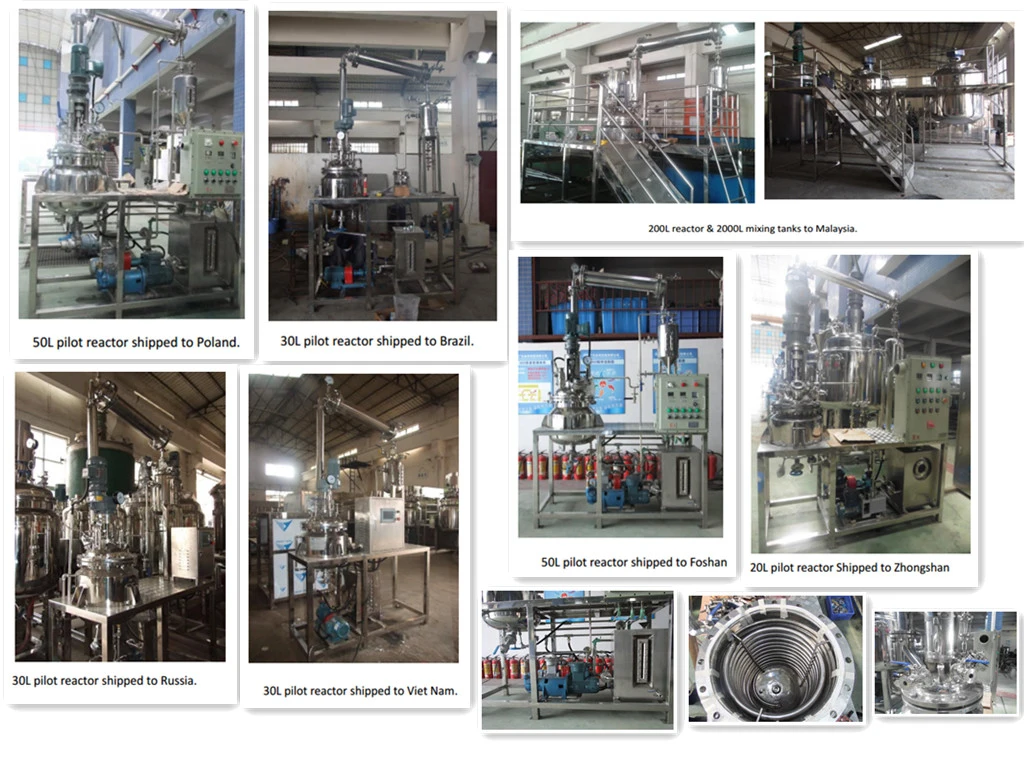

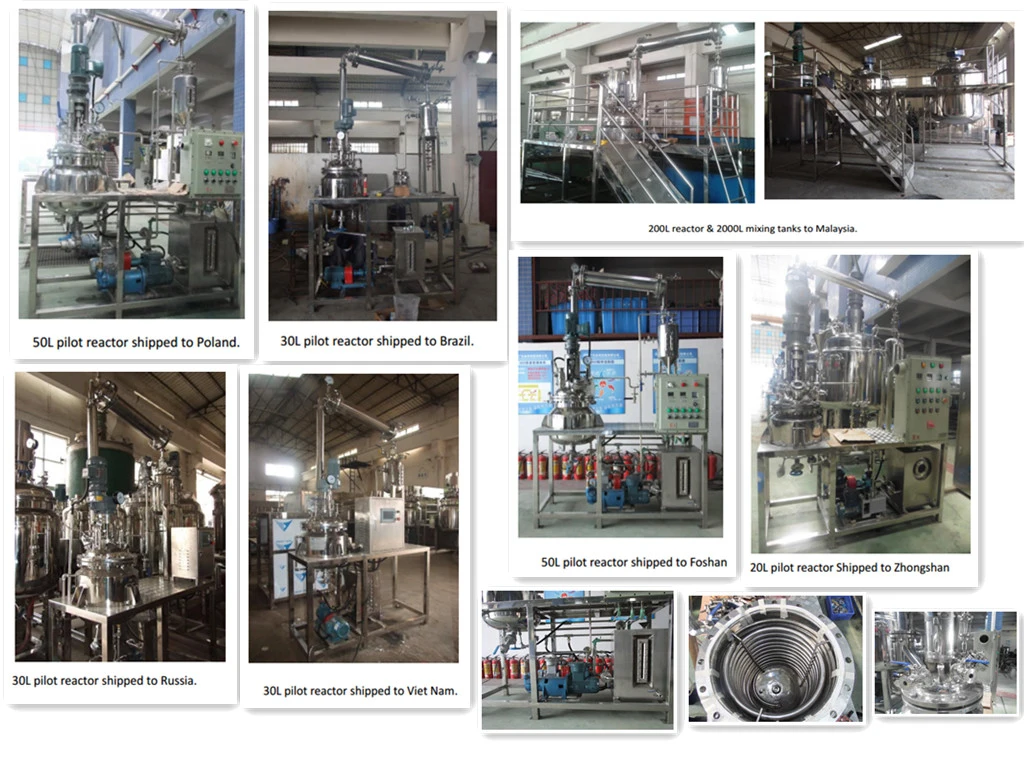

Cases

Chemical Pilot Reactor

1.Capacity 5L-200L.

2.Including jacketed reactor,condenser,storage tank,conduction oil preheating tank,hot oil pump,pipelines,valves,temperature gauge PT100,pressure gauge,platform etc.

3.Made of SUS316L and SUS304.

4.Heating and cooling by jacket or heated by jacket and cooling by inner pipe coil

Jinzong Machinery provides a full range of testing and pilot unit services for :

Reformulation of products

Development of new resins and polymer emulsions

Optimization of reactor design

Optimization of process and product quality

Jinzong Machinery also supplies skid mounted pilot units for installation at the client's site. The custom designed product reactors range in size from 10 liters to 1000 liters.

Model selection reference of reaction kettle

Composition | Instructions |

| Specification (L) | 5-200 |

| Design Pressure (Mpa) | Atmospheric Pressure or under pressure |

| Material | Carbon steel, stainless steel, enamel, graphite |

| Heating Forms | Electrical heating with medium in jacket, external half coil steam heating, external half conduction oil heating, hot water infrared heating etc. |

| Cooling Forms | Refrigeration medium in the internal pipe jacket |

| Blending Power | Model selection is made according to material viscosity, liquid-solid ratio, liquid specific gravity, solid specific gravity, solid granularity, rotation speed, paddle type, with or without baffle or internal coil. |

| Stirring blade Forms | Anchor type, frame type, flat paddle type, pitched paddle type, ribbon type, turbo type, pusher type and multiple compound type |

| Seal | Mechanical seal or stuff packing seal |

| Inner Surface Treatment | Polished or no polished |

| Discharge Valve | Flanged ball valve, open downward discharge valve and others |

| Technological Pipe Hole | Manhole, sight glass, distillation mouth, imported materials, pressure gauge port, temperature, mouth, mouth filling N2, |

Technical Parameter

| Model Parameter | Reactor Volume(L) | Mixing speed (rpm) | Heat exchange surface (m2) | Separator(L) | Total power(including heating power)(KW) |

| JZ-10 | 10 | 0-84 | 0.5 | 5 | 6.37 |

| JZ-30 | 30 | 0.5 | 12 | 12.37 | |

| JZ-50 | 50 | 1 | 15 | 18.55 | |

| JZ-100 | 100 | 2 | 25 | 19.65 | |

| JZ-150 | 150 | 2.5 | 30 | 26.2 | |

| JZ-200 | 200 | 3 | 50 | 33.5 | |

| Note: In case of inconformity of the data in the table due to technical improvement or customization, the real object shall prevail. This equipment is including: Reaction vessel, mixing system, vacuum system, condenser, separator, conduction oil preheating system, platform. 1. Heating and cooling method: 1. Heating and cooling by jacket. 2. Heating by jacket and cooling by inner pipe coil. 2. Type of electrical device: 1. Ex-proof type. 2. Normal type 3. Electric cabinet control mode: 1. Touch-screen control. 2. Button control | |||||

Since its establishment, Guangdong Jinzong Machinery Co., Ltd. has continuously adhered to innovation growth and achieved a striding development in mechanical equipment field. The product is noted for its high precision.

We not only provide stable quality of mechanical equipment, but also have an ideology of globalization. The product is noted for its high precision.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy