*Application of Automatic Flat Bottles Labeling Machine:

1.Apply for labeling flat bottles,square bottles,round bottles.

2.For double sides labeling,one side labeling,around sides labeling

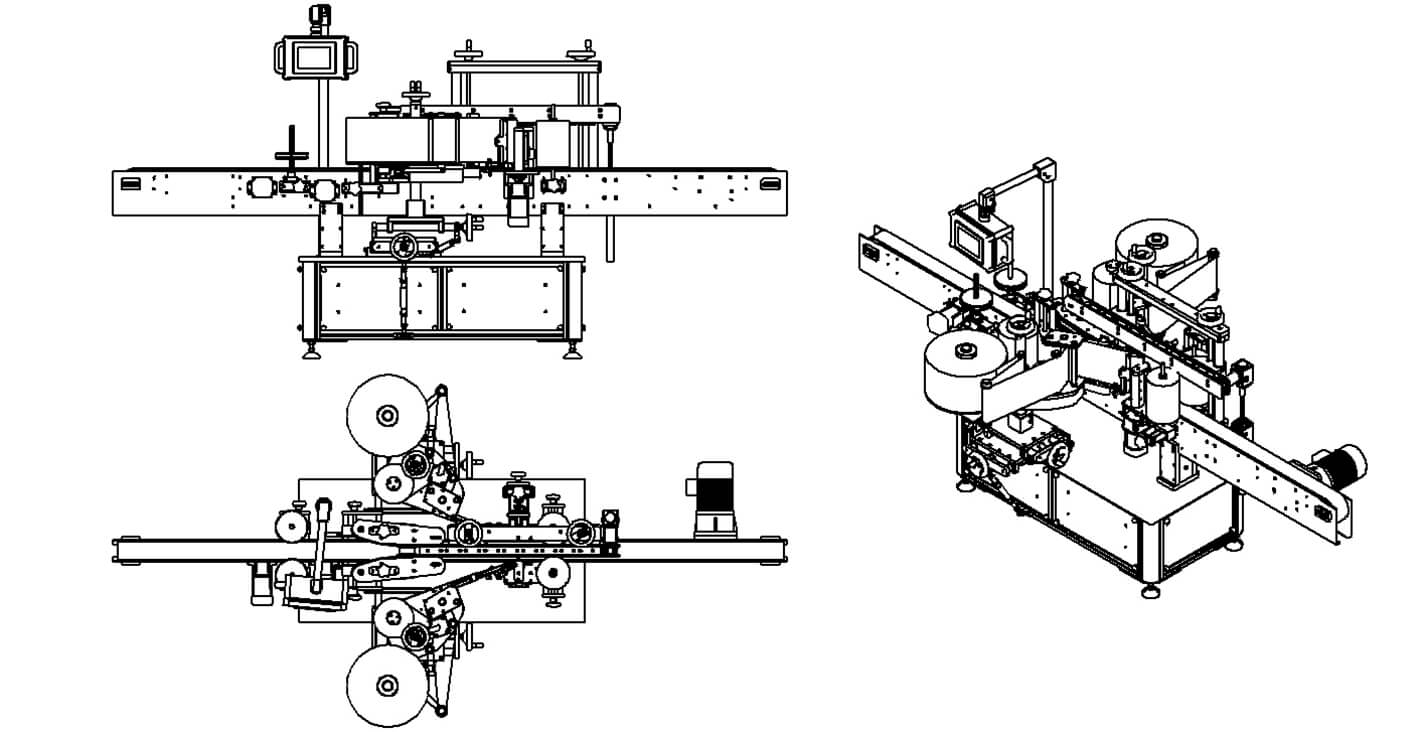

*Automatic Flat Bottles Labeling Machine Working Principle:

Put the bottles on the conveyor—Bottles separating-arrange/leading bottles-Labeling-press labels-finished

*Automatic Flat Bottles Labeling Machine Structure:

Main Motor: ①750W Panasonic servo motor; ②Panasonic servo amplifier ③Danfoss frequency inverter; ④Siemens PLC; ⑤Siemens touch screen ⑥German LEUZE labels sensor; ⑦Japan KEYENCE FS-V11 optoelectronic switch;

Conveyor: Motor 750W,speed adjustable by frequency inverter.

Bottles leading structure: Double coordinate adjustment stainless steel rail.

Plastic parts of the structure: Panasonic motor, speed adjustable, with the mechanical synchronous speed of the conveyor.

Press belt structure: Spiral Bevel Gear Drive,with the mechanical synchronous speed of the conveyor.

Scraper: Sponge spring steel plate combination.

Labels press structure: Combination unpowered sponge roller,Quick disassembling structure for different size of labels..

| NO. | Item | Specification |

| 1 | Labeling head number | 2pcs |

| 2 | Labels type | Adhesive sticker |

| 3 | Weight(height) of labels transporter | Max:200mm |

| 4 | Length of labels transporter | Max:400mm |

| 5 | Scraper | 20-200mm |

| 6 | Dimension of labeling object | thickness≤90mm height≤450mm or customer design |

| 7 | Labeling speed | 30-50m/min |

| 8 | Conveyor speed | 0-30m/Min |

| 9 | Capacity | 0-12000pcs/h |

| 10 | Tap location precision | ±0.2mm |

| 11 | Labeling precision | ±1mm |

| 12 | Label plate outside diameter | 350mm |

| 13 | Label plate inside diameter | 76.2mm |

| 14 | Qty of label plate | 2pcs |

| 15 | Size of Labels collector | 180mm |

| 16 | Method of labels collector | Rewind the labels |

| 17 | Conveyor belt | 950±50mm |

| 18 | Net weight | 500kg |

| 19 | Bottles conveying direction | From left to right |

| 20 | Labels conveying direction | From left to right |

| 21 | Dimension | L3048*W1400*H1650(mm) |

| 22 | Power supply | 220V/50Hz 3000W |

| Application labels | |

| Raw material of labels: | All the paper type labels,thin film type labels |

| Thickness of labels: | >2.5mm |

| The material of bottom labels: | Enough pull,the glassine or PET bottom labels will be better. |

| Label spacing requirement | Minimum spacing is 2.54mm,standard spacing is 3mm |

| Label size allowed error | ±0.3 mm |

| Max weight of labels: 200mm | < 200mm |

| Name | Item | Brand | Country | Units | Qty |

| PLC | S7-224 | Siemens | German | set | 1 |

| Touch Screen | Siemens | Taiwan | set | 1 | |

| Servo driver | MCDDT3520003 | Panasonic | Japan | set | 2 |

| Servo driver | MHMDD082P1U | Panasonic | Japan | set | 2 |

| Frequency inverter | FC-051PK | Danfoss | Danmark | set | 2 |

| a.c. contactor | LC1-D2510M7N | TELEMECANIQUE | German | set | 1 |

| Urgent stop switch box | 54*54 | TELEMECANIQUE | German | pcs | 1 |

| Urgent stop switch | XB2 ES542 | TELEMECANIQUE | German | pcs | 1 |

| Object sensor | FS-V11 | KEYENCE | Japan | set | 1 |

| Label sensor | GS63/6D.3-S8 | LEUZE | German | pcs | 2 |

| Power switch | 24V 6A | Meanwell | Taiwan | set | 1 |

| Conveyor motor | GV28-750-25S | Wanxin | Taiwan | set | 1 |

| Motor | M9MC60G4Y | Panasonic | Japan | set | 1 |

| Transmission | MGC30B | Panasonic | Japan | set | 1 |

| Speed controller | (includes insurance switch) | Panasonic | Japan | set | 1 |

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist