*Working Principle:

The liquid raw materials are first pre-resolved and dispersed in water pot and oil pot, then got into the emulsification boiler by the vacuum pump; powder lots are in the filler pin with air-hammer on the bottom of one side, it can distroy wall-scaling and make the powders are driven in the main pot completely, ensuring an accurate ratio of the raw materials. Powders are sucked into the main pot by vacuum system. The high- power scraped wall mixing box guarantees an intensive mixing of the materials. The high-speed homogeneous dispersing ring will break uo the materials and powders thoroughly. Trace element inlet is equiped on the side of main pot to mix them into the material without waste. Grinding miller can be set into the pot optionally to refine the materials. During the production process, cooling water in the jacket will cool down the temperature, and bubbles will be removed by vacuum de-foamation.

*Features of Toothpaste Vacuum Making Machine:

◪ Toothpaste will be made under vacuum condition..

◪ The stirrer is paddle type stirring blade with scraper,All-wave, no dead corner, choked flow, stirring system: it increases the stirring speed and mixing effect.

◪ With high speed homogenizer or colloid grinder,which is emulsify the products evenly.

◪ It can adopt one-step process to make the toothpaste in the vacuum making tanks, which can significantly reduce material loss.

◪ We can offer complete sets of the toothpaste production plant,such as automatic raw material feeding system,automatic metering and control system,etc.

| Model | ZG100 | ZG700 | DZG1500 | DZG3000 |

| Working Capacity(L) | 100 | 700 | 1500 | 3000 |

| Stirrer Speed(r.p.m) | 10--40 | 10--40 | 7-14 | 6-12 |

| Dissolving Speed(r.p.m) | 1500 | 1000 | ||

| Homogenizer Speed(r.p.m) | 3000 | 3000 | 1500 | 1500 |

| Total Power(KW) | 15. 4 | 34.2 | 50 | 78.5 |

| Size(L×W×H)mm | 2450×1550×2040 | 1760×409×2730 | 2100×2100×4400 | 2450×2450×5150 |

| The Lid Lifting Height(mm) | 880 | 1100 | 1200 | 1500 |

| Net Weight(kg) | 2500 | 3000 | 4500 | 5800 |

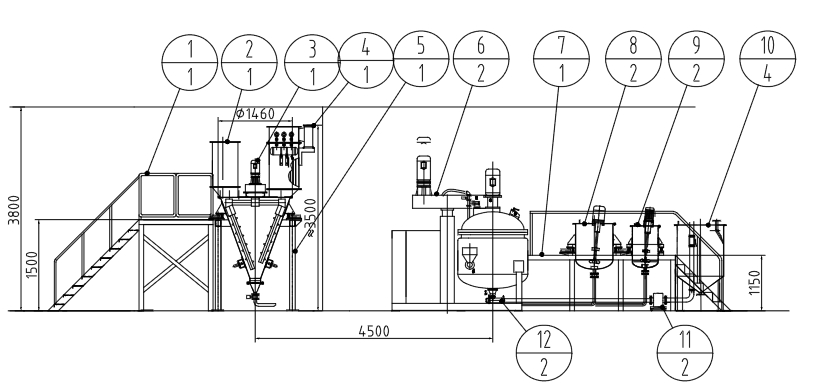

1.2 500L toothpaste vacuum homogenizer mixer main components:

◆Powder platform; ◆powder feeding hole; ◆Powder mix & metering tank; ◆4.5㎡Pulse Dust Collectors; ◆metering tank support; ◆1300L toothpaste vacuum homogenizer mixer; ◆Platform; ◆Saccharin tank; ◆Premixed tank; ◆storage tank; ◆Colloid Transfer Pump; ◆toothpaste filter;

The machine is widely used for manufacturing paste-like products, toothpaste, foods and chemistry industry,ect. This equipment includes paste machine, pre-mix boiler, glue-water boiler, powder material hopper, colloid pump and operation platform. It is best choice for making toothpaste.

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist