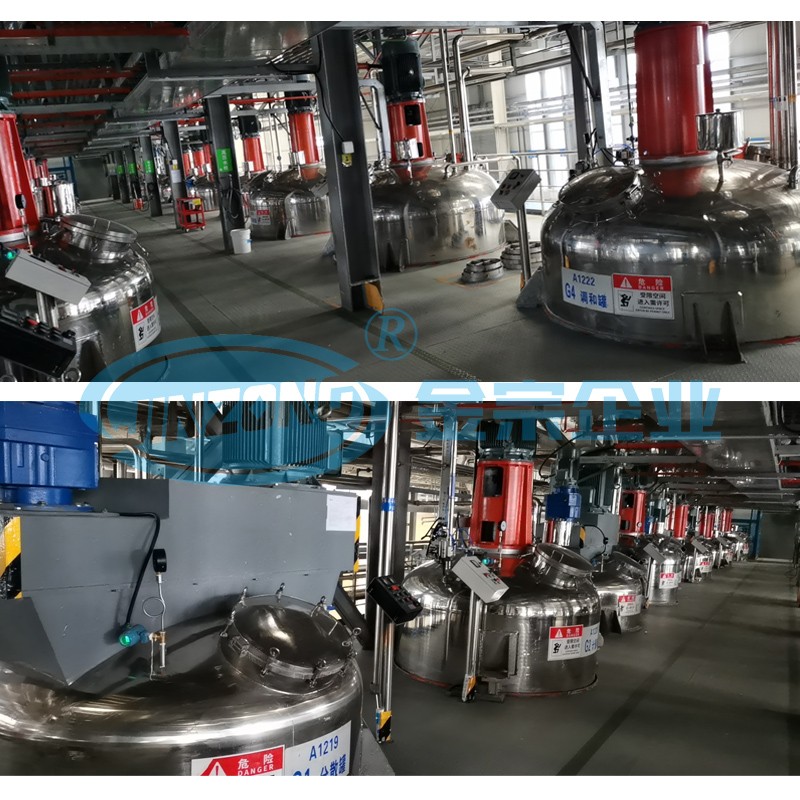

Acrylic Paint Production Line

The Paint Production equipment range from 500 tons per year capacity to 100,000 tons per year capacity. We can provide different paint production plant for oil based&water-based paint, water dilutable coating, water dispersible( latex paint), water soluble aklyd resin, water soluble expoxy resin, inorganic polymer water-based resin etc.... Water-based paint complete line consist of a couple of systems in below table:

Acrylic Paint Product Introduction

1.This product is suitable for industrial big scale production of complete sets of equipment.

2.The equipment can independently accomplish the vacuum feeding, dispersion, grinding, filtering and filling, the entire industrial process.

3.It can be customized according to the scale of production, realize the automation process control the equipment, saving space and staff, convenient management.

Acrylic Paint Production Equipment Main Features

1) It applies to small, middle, large scale production, the output from 500-50,000 ton yearly production

2) The material which contact with the product is stainless steel, ss304 or 316L

3) The vessel is mirror polished outside and inside, which make the vessel easy to clean and will

not have residual.

4) Configuration: according to different output and the particle size you need, we will equip with

high-speed disperser, Bead Mill and paint color mixing tank, filter and filling machine.

5) Installation: Our professional technician can come to your factory to install the whole system.

6) Debug: After installation, we in charge of debugging.

7) Training: Our engineers will train your workers about the operation and attention matters.

8) Maintenance: We have a strong service term, our engineer will solve your problem as earlier as possible

The complete set of equipment is composed of a feeding system, dispersive grinding and pulping system, paint mixing system, filtering system, control system, filling system, cooling system and operation platform. The production process of the assembly lines from feeding to discharging has high efficiency.

Composed of Complete Acrylic paint production line:

Powder feeding system | Automatic type or semi-auto type |

Liquid feeding system | Automatic type or semi-auto type |

Low speed agitating system: | with tank &reactor or lifting system |

Dispersing system: | Adopt one disperser with several tanks to enhance the efficiency and to save time. Electrical steering design is easy and convenient to operate. Or customized |

Grinding system: | Adopts series Horizontal Bead Mill. Required fineness can be obtained after one time circulation. For grinding color paste, Basket beads Mill or Horizontal Bead Mill (Pin type) are optional |

Filtration system: | Two kinds of filters: Bag type and Vibration type. They are optional according to different products. |

Filling system: | Two kinds of filling machines: Automatic one and Semi-automatic one. Various packing specification from 0.5L to 1000L are optional. |

Working platform: | It can be one floor, two floors, or three floors. The disperser can be placed on the top floor, grinding machine on the second floor and tinting machine on the first floor, top-to-down flow to reduce the residue inside the pipeline effectively. |

Control System: | Touch Screen, host computer, PLC control. |

5. Packaging & Shipping

Packaging

1> Outer packing: plywood case

2> Inner packing: PE film wrapping overall

6.Our Services

-Engineers avaiable to service machinery overseas

- Technological support

- Guarantee: 1 year

- Custom-make is ok for us

6.1. Pre-sale service

Act as good adviser and assisant of clients enable them to get rich and generous returns on their investments.

a. Select equipment model

b. Design and manufacturer products according to client's special requirements.

c. Train technical persnonal for clients

6.2. Service during the sale

a. Pre-check and accept products adhead of delivers

b. Send photos of machines every week and send testing video

c. Help clients to draft solving plans

6.3. After-sales services

Provide considerate services to minimize client's worries

a. Assist client to prepare for the first project.

b. Install and debug the equipment

c. Train initiative to eliminate the trouble rapidly

d. Provide technical replacement

e. After-sales team will solve problems via operating and provide technical instruction

6.4. Warranty

The warranty is 12 months

Within 12 months after equipment sold, we will provide you with parts for the damaged parts(except the demages caused by wrong operation)free of charge

We will deliver t he necessary parts via express by air or sea free of charge wihthin 12 months.

7.Company Information:

We are a professional manufacturer of cosmetic,chemical& pharmaceutical machinery and equipment more than 20 years .Product lines range from:

1> Chemical Machinery: reactors, resins production line, high speed disperser, storage tank, sand mill, three rollers mill, filter, filling macihne, paint&coating production line,paint testing machines, etc.

2> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, filling machine etc.

3> Pharmaceutical Machinery: vacuum ointment machine,sanitary stainless reaction pot,alcohol deposition can, collocation tank etc.

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist