Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery New spray paint can filling machine factory for reflux

Company Advantages

1. Our independent design for spray paint can filling machine can greatly help to improve our brand awareness. The product works very smoothly and causes less noise

2. This product can bring great relief to laborers owing to its ability to lessen pain and strain on human muscles. The product has the advantage of low energy consumption

3. The product has a sleek metal surface. The high-precision honing and grinding treatments have minimized the surface roughness of the product. It is resistant to breakage with its sturdy frame

Product Description

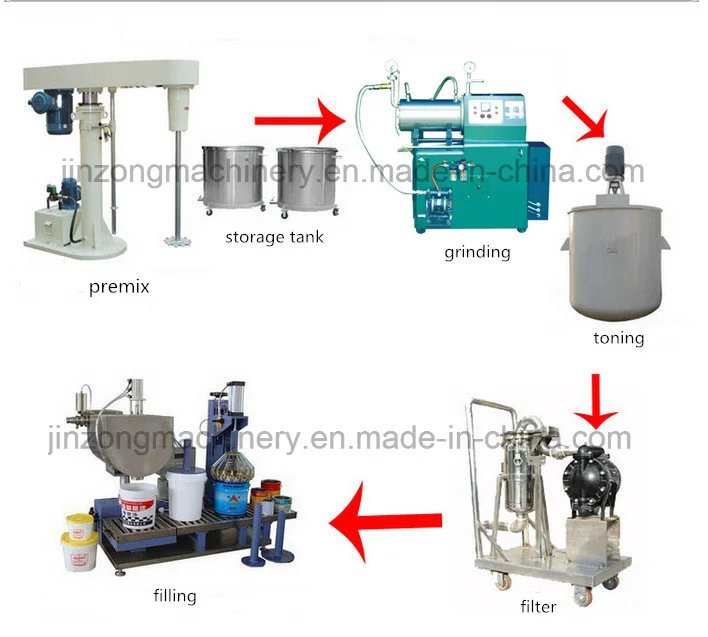

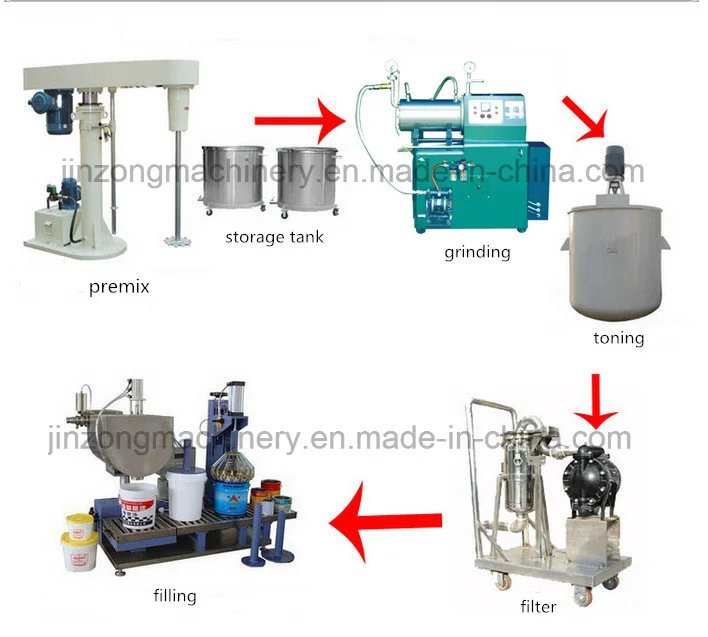

Structure

*Independently complete dispersing, griding, vacuum suction, semill-auto filling machine, etc.Slurry mixing and *color mixing executed in one tank.

*Produce water-based paint and slovent-based paint.

*Capacity tank can be 500-5000L.

***Packaging & Shipping

1> Outer packing: plywood case

2> Inner packing: PE film wrapping overall

FOB port: Guangzhou or Shenzhen

***Our Services

Pre-sales service:

1> Engineering design

2> Equipment model selection guide

3> equipment machinig

After-sales service:

1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.

2> Provide professional after-sales service engineers to abroad installation and debugging.

***Company Information

We are a professional manufacturer of cosmetic,chemical& pharmaceutical machinery and equipment more than 17 years .Product lines range from:

Product lines range from:

1> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, color paste mill, filling machine etc.

2> Chemical Machinery: paint/coating production line, high speed disperser, sand mill,three roller mill mixing equipment, separation equipment, storage tank, etc.

3> Biological and Pharmaceutical Machinery: vacuum ointment machine, fermentation tank, sanitary stainless reactor,alcohol deposition can, collocation tank etc.

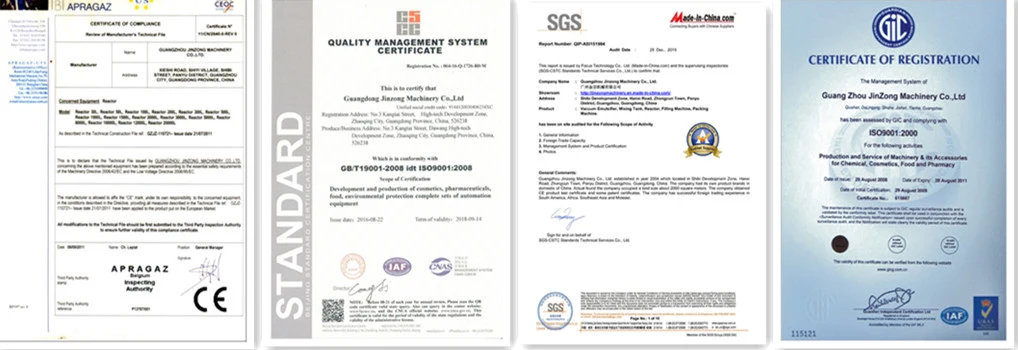

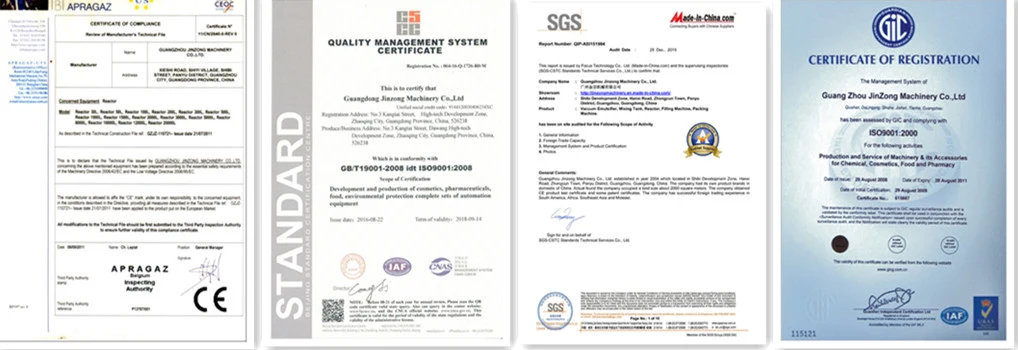

Our Certificates

***Why Choose Jinzong Machiney?

1. More than 17 years in Cosmetic and cheimical industry

2. Quality, 80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider

3. Good reputation in industry.

4.Have a Professional after-sales service engineering team

5.Large scale and strong strength

Company Features

1. The spray paint can filling machine which is manufactured with high quality and priced at competitive price accounts for renowned Guangdong Jinzong Machinery Co., Ltd.. Guangdong Jinzong Machinery Co., Ltd. has strong financial strength and professional technical R&D team.

2. Guangdong Jinzong Machinery Co., Ltd. strictly implements AQL international quality inspection standards.

3. Many senior experts who hold world advanced technologies have been employed by Guangdong Jinzong Machinery Co., Ltd. to form a strong technical team. Our business is devoted to sustainability. We're working proactively to reach zero waste to landfill by buying state-of-the-art equipment for recycling the blank waste out of manufacturing.

1. Our independent design for spray paint can filling machine can greatly help to improve our brand awareness. The product works very smoothly and causes less noise

2. This product can bring great relief to laborers owing to its ability to lessen pain and strain on human muscles. The product has the advantage of low energy consumption

3. The product has a sleek metal surface. The high-precision honing and grinding treatments have minimized the surface roughness of the product. It is resistant to breakage with its sturdy frame

| Model NO. | 500L-10000L | Layout Type | Verticle |

| Mixing Drum Shape | Disc | Additional Capabilities | Milling, Drying, Granulating, Coating |

| Operating type | Continuous Operating | Condition | New |

| Brand Name | Jinzong Machinery | Place of Origin | Guangdong, China (Mainland) |

| Voltage | 220V/380V/415V/440V | Warranty | 1 Year |

| After-Sales Service | Engineers Available to Service Machinery Overseas | Trademark | Jinzong Machinery |

| Transport Package | Plywood Case | Specification | CE, ISO, SGS |

| Origin | Guangdong, China(Mainland) | HS Code | 8419899090 |

Product Description

Structure

The production line inculding control system, grinding system, tinting system, discharging and filtration system, filling system.

Main Features*Independently complete dispersing, griding, vacuum suction, semill-auto filling machine, etc.Slurry mixing and *color mixing executed in one tank.

*Produce water-based paint and slovent-based paint.

*Capacity tank can be 500-5000L.

***Packaging & Shipping

1> Outer packing: plywood case

2> Inner packing: PE film wrapping overall

FOB port: Guangzhou or Shenzhen

***Our Services

Pre-sales service:

1> Engineering design

2> Equipment model selection guide

3> equipment machinig

After-sales service:

1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.

2> Provide professional after-sales service engineers to abroad installation and debugging.

***Company Information

We are a professional manufacturer of cosmetic,chemical& pharmaceutical machinery and equipment more than 17 years .Product lines range from:

Product lines range from:

1> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, color paste mill, filling machine etc.

2> Chemical Machinery: paint/coating production line, high speed disperser, sand mill,three roller mill mixing equipment, separation equipment, storage tank, etc.

3> Biological and Pharmaceutical Machinery: vacuum ointment machine, fermentation tank, sanitary stainless reactor,alcohol deposition can, collocation tank etc.

Our Certificates

***Why Choose Jinzong Machiney?

1. More than 17 years in Cosmetic and cheimical industry

2. Quality, 80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider

3. Good reputation in industry.

4.Have a Professional after-sales service engineering team

5.Large scale and strong strength

Guangdong Jinzong Machinery Co., Ltd. offers an extensive assortment, so that for many clients with different wishes and needs a suiting collection is possible. The product works under an effective ERP system.

Guangdong Jinzong Machinery Co., Ltd. is a company with mature sales network who makes the shopping experience more convenient. The product works under an effective ERP system.

Company Features

1. The spray paint can filling machine which is manufactured with high quality and priced at competitive price accounts for renowned Guangdong Jinzong Machinery Co., Ltd.. Guangdong Jinzong Machinery Co., Ltd. has strong financial strength and professional technical R&D team.

2. Guangdong Jinzong Machinery Co., Ltd. strictly implements AQL international quality inspection standards.

3. Many senior experts who hold world advanced technologies have been employed by Guangdong Jinzong Machinery Co., Ltd. to form a strong technical team. Our business is devoted to sustainability. We're working proactively to reach zero waste to landfill by buying state-of-the-art equipment for recycling the blank waste out of manufacturing.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy