Basket Sand Mill

*Description:

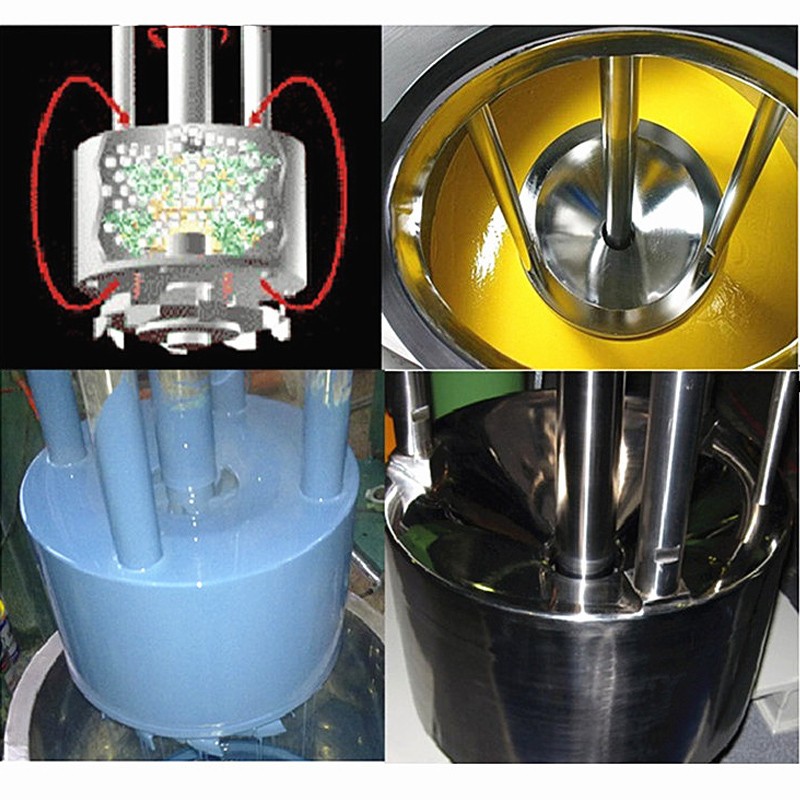

The basket is mainly composed of hydraulic lifiting system,transmission system,grinding system and so on. The hydraulic lifting system adopts the traditional hydraulic oil and the cylinder. The cylinder adopts the engineering cylinder. The cylinder is smooth and the hydraulic oil is less, And less oil spill phenomenon , hydraulic pump and motor place in the fuselage, no space, more compact, conducive to the maintenance and cleaning machine; transmission system using conventional pulley and conventional V-belt, the use of small noise process, more the use of imported bearings, long life, high speed noise small heat less; grinding system consists of all stainless steel material ,the basket stainless steel by heat treatment, high wear and corrosion resistance, the media using zirconia beads ,The bottom of the basket by the special leaves, play a pre-dispersed at the same time can make the bottom of the material up the roll, in order to achieve better grinding effect.

*Features:

1. Configure with qualified Inverter, various speed control

2. Hydraulic lifting, can be moved around

3. Integrate dispersing and grinding in one process

Model | Power (KW) | Speed (RPM) | Lifting Type | Lift Strock(mm) | Milling Medium | Milling Capacity | Medium size (mm) |

LS-4 | 4kw | 0-1500rpm | hydraulic | 700mm | 1.2-1.4 Pure zirconia beads | 30L-100L | 0.2μ |

LS-7.5 | 7.5kw | 0-1500rpm | hydraulic | 700mm | 1.2-1.4 Pure zirconia beads | 40L-200L | 0.2μ |

LS-11 | 11kw | 0-1300rpm | hydraulic | 900mm | 1.2-1.4 Pure zirconia beads | 50L-300L | 0.2μ |

LS -15 | 15kw | 0-1300rpm | hydraulic | 900mm | 1.2-1.4 Pure zirconia beads | 50L-400L | 0.2μ |

LS -18.5 | 18.5kw | 0-1300rpm | hydraulic | 900mm | 1.2-1.4 Pure zirconia beads | 80L-600L | 0.2μ |

LS -22 | 22kw | 0-1100rpm | hydraulic | 1200mm | 1.2-1.4 Pure zirconia beads | 150L-800L | 0.2μ |

LS -30 | 30kw | 0-1100rpm | hydraulic | 1200mm | 1.2-1.4 Pure zirconia beads | 250L-1200L | 0.2μ |

LS -37 | 37kw | 0-1100rpm | hydraulic | 1200mm | 1.2-1.4 Pure zirconia beads | 500L-1500L | 0.2μ |

LS -45 | 45kw | 0-1000rpm | hydraulic | 1400mm | 1.2-1.4 Pure zirconia beads | 500L-2000L | 0.2μ |

LS -75 | 75kw | 0-900rpm | hydraulic | 1500mm | 1.2-1.4 Pure zirconia beads | 600L-3000L | 0.2μ |

◪ More than 20 years extensive experience in the machinery manufacturing in Cosmetic and cheimical biological & pharmaceutical industry.

◪ Quality, 80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider. Up to now, all core machinery are with CE Certificate. We carry out products designing, manufacturing, assembling and detection fully in accordance with ISO9001-2008 Quality Management System issued by Swiss SGS Company.

◪ Good reputation in industry. Many years are awarded "defend the contract heavy credit enterprise".

◪ Have a Professional after-sales service engineering team.

◪ Large scale plant. Currently, we have 2 processing bases, Zhaoqing factory, covering a total area of more than 17,000 square meters,and Shaoguan factory,covering a total area of more than 30,000 square meters. There are more than 160 sets of processing machinery including large vertical lathe, 5-axis horizontal machining center, large planer type milling machine, automatic polishing machines etc. With the help of our strong processing capacity, we produce more than 1000 sets of equipment every year.

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist