Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery Mayonnaise manufacturing plant for business

| Warranty | 1 Year | Trademark | JINZONG |

| Transport Package | Wooden Case | Specification | SUS304, 316L |

| Origin | Guangdong | HS Code | 8474900000 |

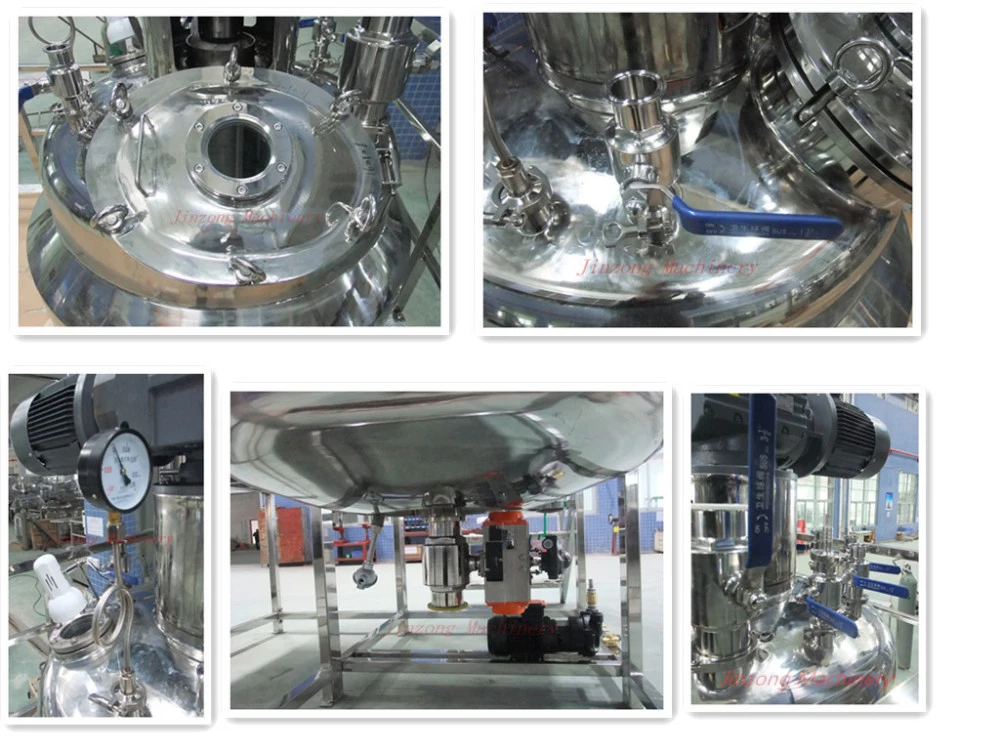

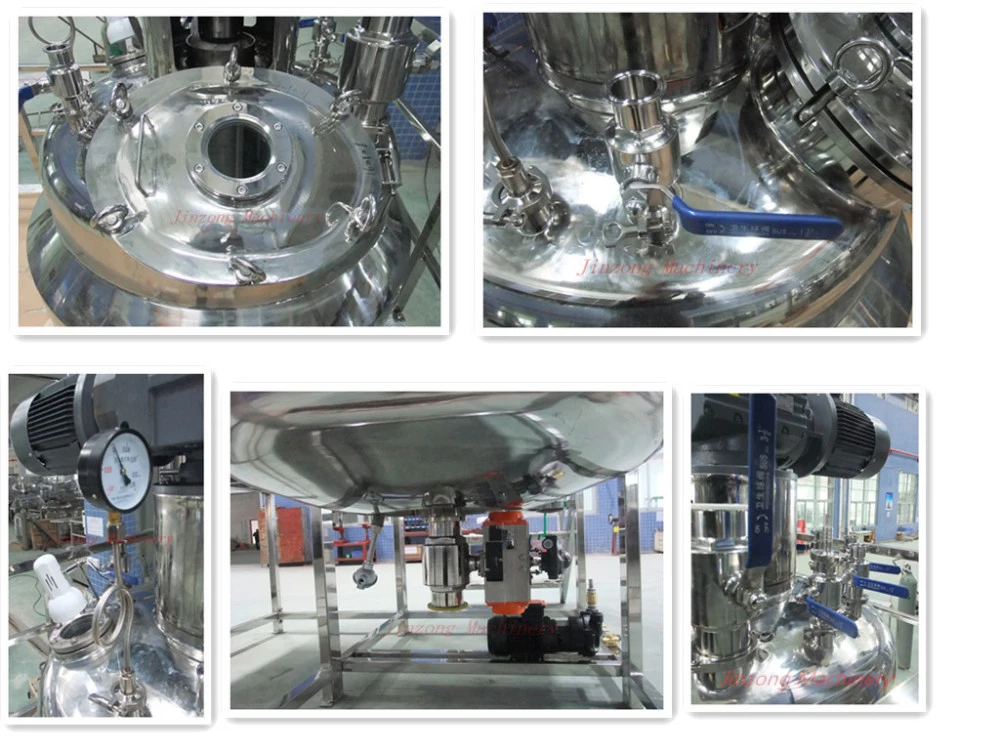

Ointment Cream mixing machine Tooth Paste Gel Manufacturing Plant

Semi-solid manufacturing Plants are ideal tools for the pharmaceutical & cosmetic industries for the production of Ointment, Cream, Lotion, Gel, Tooth Paste & emulsions & homogenization.

Fully automatic Ointment, Cream, Tooth Paste, Gel manufacturing plant consisting of

Predetermined water phase vessel.

Pre determined oil, wax, petroleum jelly phase vessel.

Vacuum Homogenizer Mixer vessel.

Vacuum Pump

Storage vessel

Interconnecting pipeline.

Transfer Pumps (Bump Pump, Lobe Pump & Metering pumps)

Integrated automatic control panel.

Working Platform

Features :

Design compliance with cGMP

Integrated Cleaning in Place-CIP.

Sterilizing In Place-SIP as an Option.

Batch Size

Available model 50 Liter to 30000 Liter working Capacity.

Materials

Product Contact SUS 316L.

Food Grade silicon rubber for seal.

Water Phase Vessel

Jacket for heating & cooling.

Heating Jacket Pressure (4 bar).

Heating by steam or hot water circulation.

Propeller stirring with top mounting.

Temperature controller & safety pressure Valve.

Bottom discharge with valve.

Wax Phase Vessel

Jacket for heating & cooling.

Heating Jacket Pressure (4 bar).

Heating by steam or hot water circulation.

Propeller stirring with top mounting.

Temperature controller & safety pressure Valve.

Bottom discharge with valve.

Manufacturing Vacuumize Homogenizer Vessel.

Jacket for heating & cooling.

Vacuumize process.

Vessel Inside Pressure (-1 / 2 Bar)

Heating Jacket Pressure (-1 / 6 bar)

Heating by steam or hot water circulation.

Agitator mixer with self pressure Teflon scrapper.

Scrapper cleanly working on both side.

High speed Homogenizer with toothed Rotor - stator type.

RPM sleeplessly with variable speed drive for agitator & Homogenizer.

High shear & pressurization of the homogenizer.

Thus homogenization of high viscosities up to 400.000 mPas.

Homogenizer mounted on lower position in the centre of vessel.

Top lid with motorized top lid for lifting & lowering.

Safety Interlock process with limit switch.

Connection for Vacuum, Charging, Eye glass window, Light glass, CIP,SIP, Pressure gauge & safety valve.

Temperature controller & safety pressure Valve.

Bottom discharge with valve.

Vacuum System

Water Ring Vacuum Pump.

Vacuum gauge & Vacuum relief valve.

Storage Vessel

Skid type storage vessel.

Bottom cone is Jacket for heating.

Inter Connecting Pipe

Inter connecting Pipe line of all vessel for transfer Water, Wax & products.

Recirculation in manufacturing vessels.

Vacuum connecting pipe.

Working Platform

Rigid structure with anti slipping embossed plat.

Made from SUS 304.

Controls & Visualization

Electric Controls with digital display.

Optional PLC Controls with HMI Touch screen.

RPM and Process time entries.

Temperature controls- Heat/cool.

Vacuum start- Stop.

Integrated Data Recording for batch.

Safety Features

Emergency stop button

Safety vacuum relief valve & Indicator Gauge.

Safety Pressure Valve.

Limit switch at top lid.

Project case

Semi-solid manufacturing Plants are ideal tools for the pharmaceutical & cosmetic industries for the production of Ointment, Cream, Lotion, Gel, Tooth Paste & emulsions & homogenization.

Fully automatic Ointment, Cream, Tooth Paste, Gel manufacturing plant consisting of

Predetermined water phase vessel.

Pre determined oil, wax, petroleum jelly phase vessel.

Vacuum Homogenizer Mixer vessel.

Vacuum Pump

Storage vessel

Interconnecting pipeline.

Transfer Pumps (Bump Pump, Lobe Pump & Metering pumps)

Integrated automatic control panel.

Working Platform

Features :

Design compliance with cGMP

Integrated Cleaning in Place-CIP.

Sterilizing In Place-SIP as an Option.

Batch Size

Available model 50 Liter to 30000 Liter working Capacity.

Materials

Product Contact SUS 316L.

Food Grade silicon rubber for seal.

Water Phase Vessel

Jacket for heating & cooling.

Heating Jacket Pressure (4 bar).

Heating by steam or hot water circulation.

Propeller stirring with top mounting.

Temperature controller & safety pressure Valve.

Bottom discharge with valve.

Wax Phase Vessel

Jacket for heating & cooling.

Heating Jacket Pressure (4 bar).

Heating by steam or hot water circulation.

Propeller stirring with top mounting.

Temperature controller & safety pressure Valve.

Bottom discharge with valve.

Manufacturing Vacuumize Homogenizer Vessel.

Jacket for heating & cooling.

Vacuumize process.

Vessel Inside Pressure (-1 / 2 Bar)

Heating Jacket Pressure (-1 / 6 bar)

Heating by steam or hot water circulation.

Agitator mixer with self pressure Teflon scrapper.

Scrapper cleanly working on both side.

High speed Homogenizer with toothed Rotor - stator type.

RPM sleeplessly with variable speed drive for agitator & Homogenizer.

High shear & pressurization of the homogenizer.

Thus homogenization of high viscosities up to 400.000 mPas.

Homogenizer mounted on lower position in the centre of vessel.

Top lid with motorized top lid for lifting & lowering.

Safety Interlock process with limit switch.

Connection for Vacuum, Charging, Eye glass window, Light glass, CIP,SIP, Pressure gauge & safety valve.

Temperature controller & safety pressure Valve.

Bottom discharge with valve.

Vacuum System

Water Ring Vacuum Pump.

Vacuum gauge & Vacuum relief valve.

Storage Vessel

Skid type storage vessel.

Bottom cone is Jacket for heating.

Inter Connecting Pipe

Inter connecting Pipe line of all vessel for transfer Water, Wax & products.

Recirculation in manufacturing vessels.

Vacuum connecting pipe.

Working Platform

Rigid structure with anti slipping embossed plat.

Made from SUS 304.

Controls & Visualization

Electric Controls with digital display.

Optional PLC Controls with HMI Touch screen.

RPM and Process time entries.

Temperature controls- Heat/cool.

Vacuum start- Stop.

Integrated Data Recording for batch.

Safety Features

Emergency stop button

Safety vacuum relief valve & Indicator Gauge.

Safety Pressure Valve.

Limit switch at top lid.

This product is currently very popular in the market and is being adopted by more and more people. The product works very stably, which helps meet users' production schedules.

This product has achieved good results in practical applications. The product works very stably, which helps meet users' production schedules.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy