Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Mayonnaise Manufacturing Plant Mixing Tank with Inline or Bottom Homogenizer

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

| Trademark | JINZONG | Transport Package | Wooden Case |

| Specification | SUS304, 316L | Origin | Guangdong |

| HS Code | 8419899090 |

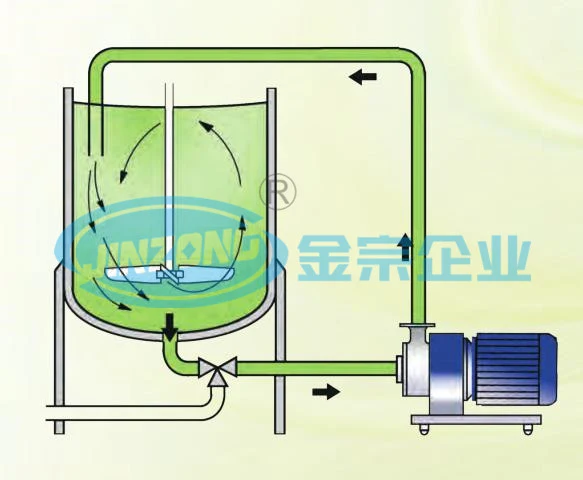

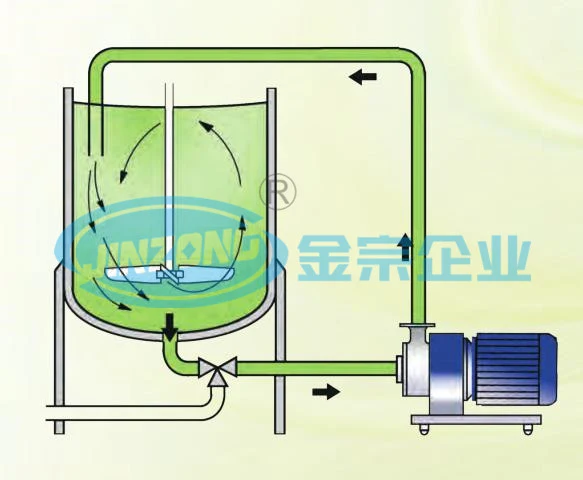

Mayonnaise manufacturing Plant mixing tank with inline or bottom homogenizer

We are leading manufacturer and exporter the best collection of automatic mayonnaise manufacturing plant. This unit is capable of carrying out the entire process, including rapid preparation of premixes, hydration of thickening and stabilizing agents and preparation of the final oil-in-water emulsion. We offer this collection at market minimal selling price ranges. Completely made of the high-speed motor with a stirrer. Specially designed in and out a system of cutters and blades.

Mayonnaise is an oil-in-water emulsion. The ingredients used in mayonnaise are given in the following phases-

Oil Phase only containing oil

An egg phase only containing egg substances(Whole egg, egg yolk or mixer)

A vinegar phase which can contain vinegar, spices and flavors

A water phase

A typical method for manufacture of mayonnaise would be as follows:

In the first stage of production, the egg, which may be used in either liquid or powder form is

dispersed into the water. This acts as the emulsifying agent.

For mayonnaise packaging solution also afford aseptic sterilizer with deaeration system, in multiple tube and tube in tube design for filling the processed pulp in to bag in drum thru, aseptic fillers. The modular structure of the production line for fine food results in the best flexibility. the continuous line offers the possibility of manufacturing a wide range of products as the processing parameters of the system can easily be altered or adapted during processing. Then filler available with single head/twin heads/ four heads filling machine suitable for fill the cans of mayonnaise and at last a packing machine is attached to pack the mayonnaise cans hygienically.

Packing info

Slushing oil on metals to form a protective coating against rust, 1 set/PE film and then plywood case.

We are leading manufacturer and exporter the best collection of automatic mayonnaise manufacturing plant. This unit is capable of carrying out the entire process, including rapid preparation of premixes, hydration of thickening and stabilizing agents and preparation of the final oil-in-water emulsion. We offer this collection at market minimal selling price ranges. Completely made of the high-speed motor with a stirrer. Specially designed in and out a system of cutters and blades.

Mayonnaise is an oil-in-water emulsion. The ingredients used in mayonnaise are given in the following phases-

Oil Phase only containing oil

An egg phase only containing egg substances(Whole egg, egg yolk or mixer)

A vinegar phase which can contain vinegar, spices and flavors

A water phase

A typical method for manufacture of mayonnaise would be as follows:

In the first stage of production, the egg, which may be used in either liquid or powder form is

dispersed into the water. This acts as the emulsifying agent.

For mayonnaise packaging solution also afford aseptic sterilizer with deaeration system, in multiple tube and tube in tube design for filling the processed pulp in to bag in drum thru, aseptic fillers. The modular structure of the production line for fine food results in the best flexibility. the continuous line offers the possibility of manufacturing a wide range of products as the processing parameters of the system can easily be altered or adapted during processing. Then filler available with single head/twin heads/ four heads filling machine suitable for fill the cans of mayonnaise and at last a packing machine is attached to pack the mayonnaise cans hygienically.

Packing info

Slushing oil on metals to form a protective coating against rust, 1 set/PE film and then plywood case.

The product is far less likely to make production errors or sacrifice production quality for speed. It can bring the best results. The product has an automatic data collection function.

The use of this product offers great flexibility to manufacturers in terms of investment allocation, such as shifting the investment in labor to product development. The product has an automatic data collection function.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy