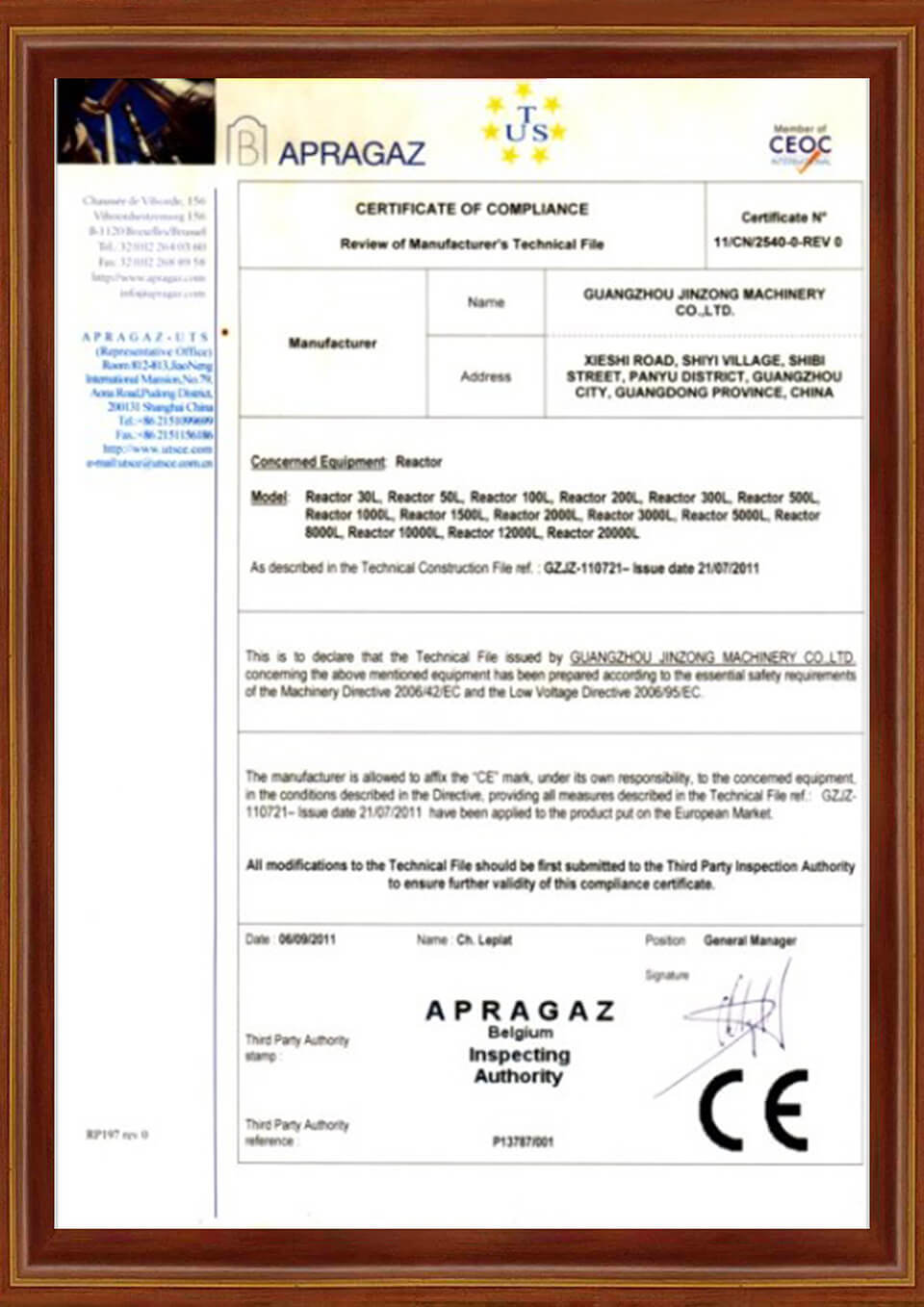

Company Advantages1. Jinzong Machinery has to undergo a conformity assessment to demonstrate that it meets legal medical requirements to ensure it is safe and performs as intended. It is highly resistant to UV light and flame

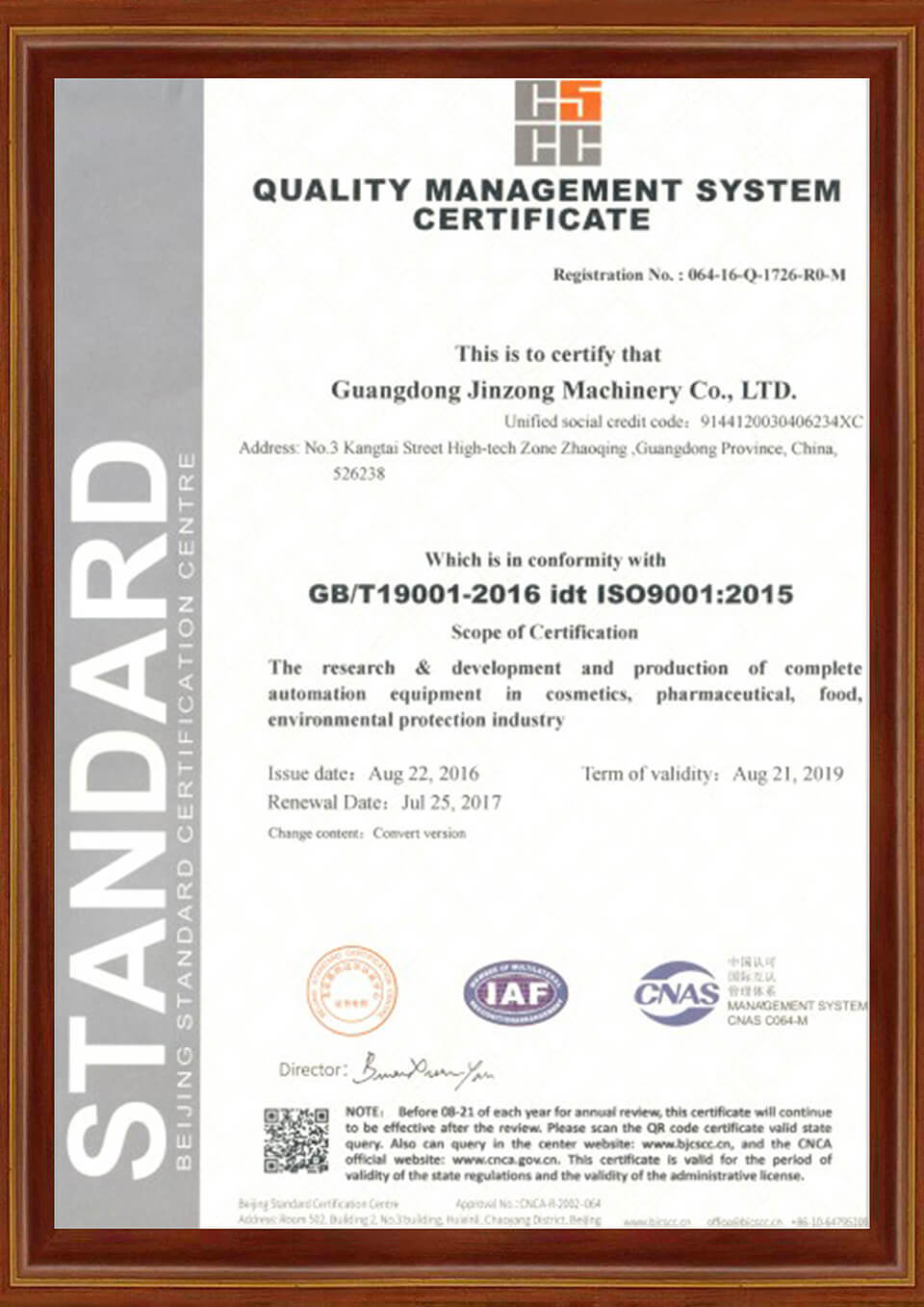

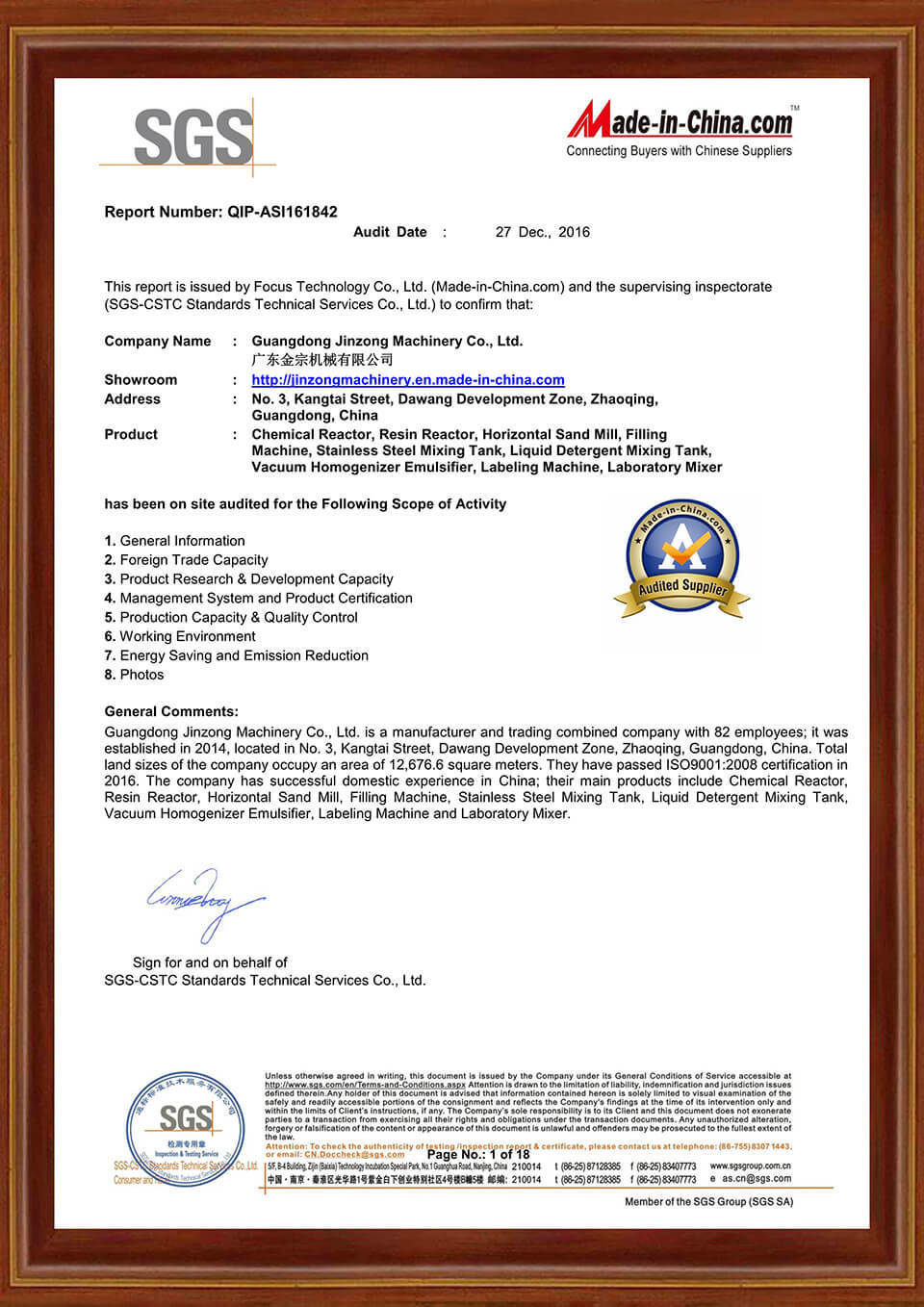

2. The achievements all show that

Jinzong Machinery's persistence and efforts on quality. The product works very stably, which helps meet users' production schedules

3. The product is stain and liquid resistant. It is coated or polished with a layer that goes through special dipping treatment, which enables it to resist splodge splotch, acid and alkaline. Made of stainless steel, it is highly durable

4. This product stands out for its quality seams. Its seams are strong enough to withstand the pressure of high-traffic areas and points of stress. The product is noted for its high precision

5. The product is innocuous. It has passed the ingredient testing and does not contain Chlorinated phenols, dimethyl fumarate, or other toxic chemicals. The product has the advantage of low energy consumption

*Solvent distillation recovery system:

The unit mainly consists of distillation tank, vertical condenser, horizontal condenser, reflux drum, working platform and control panel.

Material: SS304 or SS316L

Design Pressure:-1 -10 Bar (g) or ATM

Work Temperature:0-200 °C

Volumes:5~30000L, customized

Control panel: manual button controller, manual touch-screen controller, automatic touch-screen controller.

If you have any technical requirement,feel free let us know . We can design the tanks according to your requirement .

*MAIN COMPOSITION of distillation tank:

Distillation tank is mainly composed of tank body, mixing system and accessories. The tank body includes inner cylinder, outer cylinder, jacket and supporting foot, etc. Rock wool filling is used as insulation layer between inner cylinder and outer cylinder if needed, jacket form is integrate jacket.

The accessories mainly include manhole, mirror, light, material and liquid inlet and outlet pipe, thermometer, pressure gauge or customized.

Jinzong solvent distillation recovery system is widely applied for organic solvent recovery and concentration and evaporation of liquid materials in pharmacy, food, and chemical industries. External heat type alcohol recovery tower can also be used for low temperature concentration with small batch.

Company Features1. Provided diversified and professional makes Jinzong Machinery stand out in ointment filling machine field. Jinzong Machinery puts a large investment in technical power for the development.

2. Our ointment manufacturing machine is a product with a high cost-performance ratio and appreciates exceptional quality.

3. Jinzong Machinery strongly emphasizes the importance of applying high technology. Insisting on , Jinzong Machinery has become a leading pharmaceutical production line manufacturer in this industry. Please contact us!