Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery jr preparation of pharmaceutical process series for reaction

1. Using preparation of pharmaceutical process materials, pharmaceutical equipment is more applicable in hard conditions.

2. The product has strong colorfastness. It is treated with a soil release finishing agent which can enhance its endurance to frequent washing.

3. Except the quality, Jinzong Machinery is also famous for its service.

*Description:

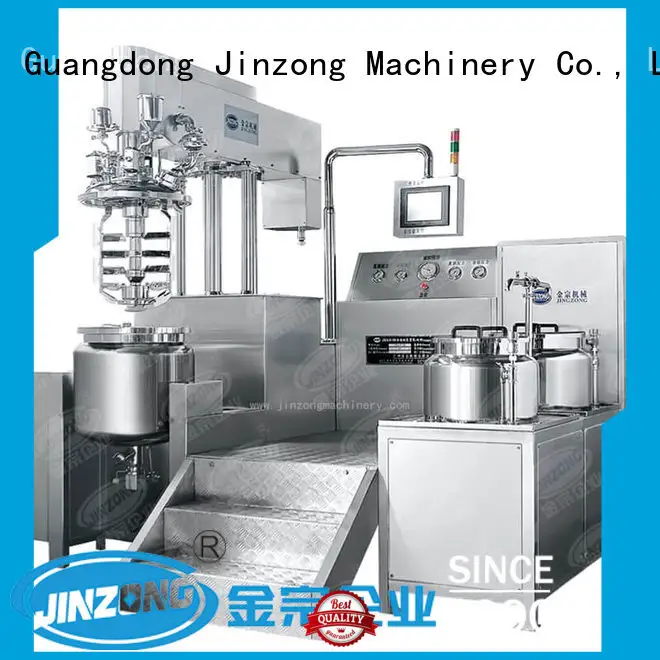

The YGA vacuum unguent machine is a new-generation intelligent unguent machine independently developed by Jinzong. It is automatically controlled by PLC and the system can freely switch among several control modes, such as HMI mode and batch operation with remote central control room. For industries with special requirements. It can truly realize remote full-automatic operation without human interference on the field, thus realizing safe economical and efficient production.

Its automatic feeding, discharging and cleaning systems hydraulic lifting and tilting systems as well as overall outlook design all conform to GMP and FDA specifications.

The YGA vacuum unguent machine proves to be the first choice for pharmaceutical and chemical industries to manufacture high-grade products like creams and ointments.

YGA Series homogenizer Vacuum Emulsifying Mixer system is a high shear dispersion paste making system. It is to distribute one or more phases into another continuous phase efficiently, rapidly and evenly, but in general, each phase is incompatible with each other. Because of the high tangential velocity and the strong kinetic energy brought by the high frequency mechanical effect produced by the high speed rotation of the rotor, the material is subjected to strong mechanical and hydraulic shearing, centrifugal extrusion, liquid friction, impact tearing and turbulence in the narrow gap between the stator and the rotor, so that the immiscible solid, liquid and gas phases are under the combined action of the corresponding mature technology and appropriate additives. It evenly and finely disperses emulsification in an instant, and eventually obtains stable high-quality products through high-frequency circulation and reciprocation.

*Advantages:

The system is specially designed according to making technology of ointment and cosmetics products. It consists of pretreatment pot, vacuum emulsifying mixing pot, vacuum pump, hydraulic system, feeding system, electrical control system and working platform. The unit has the advantages of simple operation, stable performance, good homogeneity, high production efficiency, convenient cleaning, reasonable structure, less floor area and high automation.

| Model | Volume of Main Tank (L) | Volume of Dissolving tank (L) | Dimension | Total Power (kw) | Weight (kg) |

| 50 | 100 | 45/65 | 2700x2500x2000-2700 | 9 | 1700 |

| 100 | 130 | 70/100 | 2900x2500x2000-2800 | 10 | 1900 |

| 200 | 260 | 120/190 | 3200x3000x2400-3350 | 13 | 2400 |

| 300 | 375 | 150/260 | 3350x3100x2550-3650 | 17 | 2700 |

| 500 | 620 | 300/460 | 3800x3400x2850-4100 | 25 | 3600 |

| 1000 | 1250 | 620/900 | 4150x4150x3700-5200 | 32 | 5400 |

◪ Large continuous workload, especially suitable for continuous processing of single product.

◪ Simple operation and better homogeneity of emulsification;

◪ Mixing is controlled by Panasonic Electrical Frequency Converter, which saves electricity and has strong mechanical protection function. Constant rotating distance makes the mechanical operation more stable. The production speed can be freely selected and the cover of the pot can be freely lifted by the hydraulic lifting system.

◪ The main design of homogenizer is from Germany. High shear eddy current emulsifying mixing, slow scraping mixing, automatic close to the bottom and wall of the pot;

◪ Good sealing, long service life, homogenizer can work 24 hours continuously.

◪ Vacuum pumps are manufactured by German Nasim (formerly Siemens), buttons are manufactured by Japan Fuji, frequency converters are manufactured by Japan Panasonic, and electrical control parts are manufactured by Siemens.

◪ Vacuum suction is used, especially for powder materials. Vacuum suction is used to avoid dust flying. The whole production process is carried out under vacuum conditions to prevent material from producing bubbles under high-speed stirring, which can meet the requirements of dust-free and sterile.

◪ The material of the whole bracket of the equipment is stainless steel, 300 U polishing inside and outside of the pot, the material of the contact part of the container is 316L stainless steel to ensure the stability of the equipment, which is suitable for GMP and daily chemical specifications.

◪ Safety protection functions make production safer.

◪ The equipment integrates vacuum defoaming, stirring, homogenizing, heating and electronic control functions. It consists of vacuum homogenizing emulsifying pot, oil-phase pot, water-phase pot, vacuum system and hydraulic lifting system.

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. specializes in R&D, manufacturing, sales, and service of preparation of pharmaceutical process as an integrated pharmaceutical equipment service provider.

2. [Enterprise Title ] engineers and engineers possess the finest top work expertise of pharmaceutical injection whole set dispensing machine system .

3. Anything necessary about our ointment filling machine , please just feel free to contact us immediately. Ask! Guangdong Jinzong Machinery Co., Ltd. will do our utmost to meet our customers' satisfaction. Ask! By concentrating on equipment used in pharmaceutical industry , we believe that we can become well-known global enterprise. Ask! The tenet of Jinzong Machinery is the key to our continuous development and growth. Ask!

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)