Horizontal Sand Mill

Brief Introduction

Horizontal disc grinder is widely used in coatings equipment and new energy production equipment.This machine adopts eccentric disc grinding structure and is installed on the stirring in a certain distribution order.This system overcomes the shortcoming of uneven distribution of grinding media in tradittional grinder,makes the grinding media get maximum energy transfer and high grinding efficiency.It is produced by BURGMAN.Strong cooling double-end mechanical seal deivce has good sealing effect and reliable operation.In the separation system,a large flow dynamic slot separator is used.and there is no blockage at the outllet under the condition of large flow.The flow area is large,and the width of the slot is 0.05mm-2.0mm.Abrasive media over 0.1mm can be used.According the specific requirements of materials,the grinding chamber can be designed according to different materials.

Performance

1. Open separation system DCC system

2. Most of the grinding balls are automatically blocked back in the separation area.

3. The grinding medium is pulled back to the grinding area by centrifugal force,and the product enters the separation area through the holes on the grading disc along the axis direction

4. The formation of internal circulating flow effictively counterats the flow of axial products.

5. The replacement of abrasive disc is cheap and convenient.

6. The adrasive disc can be made of different special materials

7. Non-spherical abrasive medium can be used.

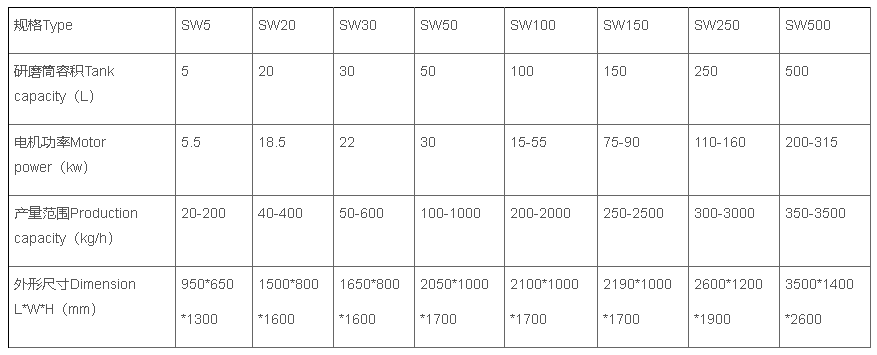

Parameter

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist