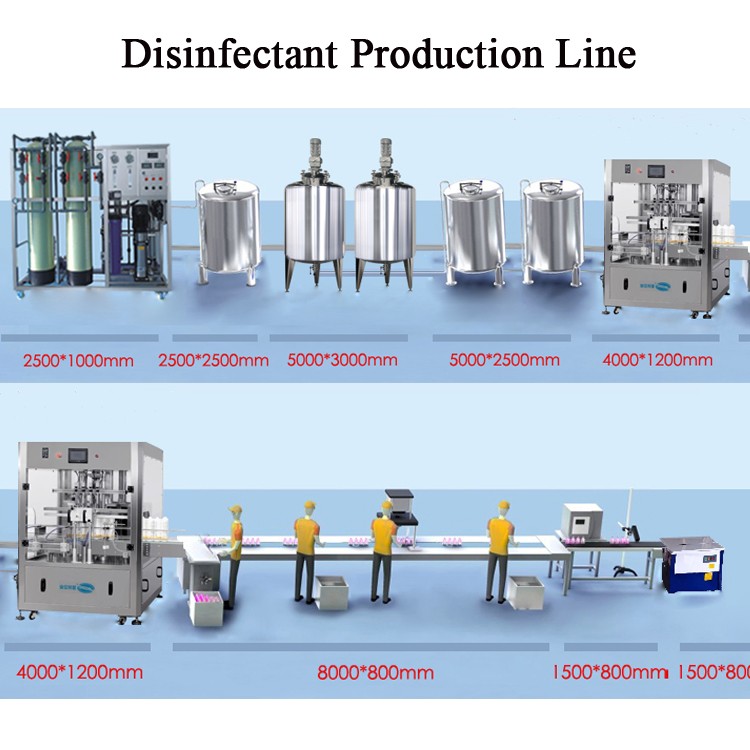

Disinfectant Liquid Production Line

1.RO water treatment unit

*Description:

The water treatment machine is suitable for such industries as cosmetics, pharmacy, food and electronics has been deeply favored by users for its stable water quality and simple operation.

The system solves the troubles of frequent regeneration and cleaning during the use of ion exchanging water purifier. By adopting physical principle, it enables the water to pass the reverse osmosis film with a diameter of one ten-thousandth of a micron and separates impurities, ion, microbes and colloids in the water, so as to meet the water requirements in cosmetics industries.

Reverse osmosis process uses semi permeable spiral wound membranes to separate and remove dissolved solids, organic, pyrogens, sub micron colloidal matter and bacteria from water. Feed water is delivered under a pressure of approximately 16 kg/cm2 through reverse osmosis membranes. Water permeates the minute pores of the membrane and is delivered as purified water. Impurities in the water are concentrated in the reject stream and flushed to drain. Reverse osmosis is capable of removing 90%-99% of total dissolved solids (TDS), 99% of organic, including pyrogens, and 99% of all bacteria in the feed water.

According to the customer's local water testing report,we adopt different equipments to produce drinking water of pure water or mineral water,etc.

*Features:

1. Continuous production, no need to regenerate, reduce labor intensity;

2. High efficiency, fully automatic operation, easy to operate and maintain;

3. Online conductivity monitoring to ensure that the water output meets the requirements;>

4. Can remove organic matter and bacteria more than 98 %;

5. If the original water quality is poor or the water demand is high, JRO reverse osmosis can also be connected with ion exchange equipment to ensure various water requirements.

6. Can add anion & cation mixing bed,EDI,UV lamp,etc..

Technical Specifications

Model | Productivity(t/h) | Power(kw) | Recovery rate(%) | Desalination rate(%) |

JRO-0.5 | 0.5 | 1.5 | 50 | 97 |

JRO-1.0 | 1.0 | 1.5 | 50 | 97 |

JRO-2.0 | 2.0 | 1.5 | 70 | 97 |

JRO-3.0 | 3.0 | 2.5 | 75 | 97 |

JRO-5.0 | 5.0 | 5.5 | 75 | 97 |

JRO-6.0 | 6.0 | 5.5 | 75 | 97 |

JRO-8.0 | 8.0 | 7.5 | 75 | 97 |

JRO-10.0 | 10.0 | 7.5 | 75 | 97 |

Application

Chemical industry, power plant desalination water, electrodeionization ultra pure water, medical industry, aviation cleaning, food and beverage industry, municipal heating,

softened circulating water, living water purification, brackish water desalination, sea water desalination,industrial waste water treatment, reclaimed water reuse, rural area drinking water project, pharmacy inductries,etc.

2.Disinfectant making mixing tank

JY Disinfectant making mixing tank can divided to JYA normal type and JYB vacuum type according to the main boiler’s basic structure. The mixing type has the multi-level mixing blade&frame wall-scraping mixing blade and other combinations .And can also add the AES self-absorption dissolving decollators or homogenizer accordingly customer’s requirement.

The series of products have the mixing paddles of many structural shapes for choice ,and the vessel body has many shapes such as normal temperature, heating, normal pressure and vacuum, the product has the advantages of high productivity, low energy consumption ,strong adaptability and broad usages, and is the ideal equipment to produce liquid washing prodcuts.

Disinfectant making mixing tank Technical Specifications

Model | Volume of Main Pot | Mixing motor | (L*W*H)mm Dimension | Weight (kg) | |

Power (kw) | Speed (rpm) | ||||

JY-200 | 260 | 2.2 | 0-74 | 2000*2000*2650 | 1600 |

JY-300 | 375 | 3 | 0-74 | 2100*2100*2750 | 1900 |

JY-500 | 620 | 4 | 0-63 | 2250*2250*3050 | 2500 |

JY-1000 | 1250 | 5.5 | 0-50 | 2600*2600*3500 | 4000 |

JY-2000 | 2600 | 7.5 | 0-42 | 2800*2800*4000 | 6000 |

JY-3000 | 3800 | 11 | 0-42 | 3000*3000*4200 | 9000 |

JY-5000 | 6500 | 15 | 0-42 | 3300*3500*4800 | |

JY-10000 | 12500 | 22 | 0-30 | ||

Disinfectant making mixing tank Application

* Disinfectant making mixing tank Application:

It is suitable for manufacturing products in cosmetic and food area. In food, like jalapenos, mayonnaise, chocolate, etc products. In cosmetic, like shampoo, liquid soap, shower gel, etc. It integrates mixing, homogenizing, heating, cooling, pump discharging finished products and defoaming(optional) functions. It is the ideal equipment for liquid products in domestic and international factories. The pot body is welded by three-layer stainless steel plate. The tank body and the pipes adopt mirror polishing, wahich fully conforms to GMP requirements. According to customer requirement, the tank can heat and cool materials. The heating way including steam heating and electric heating, Easy to discharge, bottom discharge or by transfer pump.

*In general, Disinfectant making mixing tank application products as following:

Desinfectant,Shampoo, liquid soap, bath shower gel; Dish washing, hand washing, lubricating oil; AES、AESA、LAS materials; jalapenos, mayonnaise, chocolat; All kinds of daily chemical liquid wash products.

3.Automatic packing line

6 head piston filling machine technical parameters: 4Nozzle for 500ml

1. Filling nozzle: 6/4

2. Filling volume:10-100ml /100ml-1L

3. Filling speed: 30-40BPM based on 50ml bottle

4. Filling precision: ±1%

5. Frame material: 304 SUS

6. Program control: PLC+ touch screen

7. Filling nozzle, tank, parts connected with liquid: 316#, silica gel, POM

8. Air pressure: 0.6-0.8Mpa

9. Conveyor: 82mm POM chain belt, 0-15m/min, H: 800±25mm

10. Conveyor motor: 750W frequency speed governing motor

11. Power: 2.2KW, 380V, three phase five wire

12. Tank: 150L, with liquid level, the input pipe installed into the bottom to prevent foam

4 wheel screw capping machine technical parameters:

13. Suitable bottles: According to customer samples

14. Cap distributor: Vibration shaking plate

15. Capping way: Electric screw capping

16. Capping speed: 40-50BPM

17. Conveyor: Share with filling machine

18. PLC + touch screen: Share with filling machine

19. 7. Power: 200W, 220V

Labeling machine technical parameters:

20. Suitable bottles: According to customer samples

21. Suitable label: Sticker roll label, not transparent

22. Capacity: >50BPM

23. Labeling precision: ±1mm

24. Conveyor: 82mm POM chain belt, 0-15m/min, H: 800±25mm

25. Power: 220V, 600W

26. Program control: PLC + touch screen

27. Roll label inner diameter: 76mm, Max outer diameter: 300mm

Main Configuration:

1. Frame, under-chassis, guard rail: 304 SUS

2. Filling nozzle, tank, parts connected with liquid: 316#, silica gel, POM

3. Pneumatic component: Taiwan AIRTAC

4. PLC + touch screen: Siemens

5. Sensor: German LEUZE

6. Converter: Schneider

7. Conveyor: 82mm chain belt, AC motor

8. Exposed parts: stainless steel, anodized aluminum alloy, electroplated 45 # steel, plastics.

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist