Glass-lined reactor is widely used in reaction, evaporation, concertration, composition, extraction, saponification, mineralization, chlorination, nitration etc. Of chemical, pharmaceutical, dye, pesticide, organic synthesis, petroleum, food additives, defense industry and scientific research. Corrosion resistance: It resists all kinds of thickness of mediums like inorganic acid, organic acid, organic solvent and weak base etc. But it isn't suitable for strong base, hydrofluoric acid, fluorion medium, phosphoric acid whose temperature is over 180 degree and thickness is over 30% etc.

Introduction:

The enamel/enamelled glass reaction kettle(reaction tank) is a chemical equipment that enamels glass enamels containing high silicon dioxide and is lined on the inner surface of a steel container, and is then evenly bonded to the metal surface by burning at high temperatures. Therefore, the enamel reaction kettle has the dual advantages of glass stability and metal strength, and is an excellent corrosion resistant chemical equipment. The enamel reaction kettle(enamel reaction tank) is widely used for reaction, evaporation, concentration and synthesis in industrial production and scientific research such as chemical industry, medicine, dyes, pesticides, organic synthesis, petroleum, food manufacturing and defense industry. , extraction, polymerization, saponification, mineralization, chlorination, nitrification, etc. to replace expensive stainless steel and non-ferrous metals.

Reactor kettles, also known as reaction tanks, distillation tanks, water bath kettles, neutralization kettles, dissolution kettles, condensation kettles, and many other names are named based on the chemical reactions of their own products.

Our chemical reaction tanks, enamel / glass enameled reaction kettle are all fired with a specific specification electric furnace. Enamel/glass enameled equipment has smooth surface, wear resistance, heat resistance, easy washing, non-polluting materials, low price, and not easy porcelain.

Enamels and enamels are only different in name, and there is actually no essential difference. Specially speaking, enamels are low-temperature enamels(690-780 °C), and enamels are high-temperature enamels(880-1050 °C). The melting temperature of the steel plate is 1300 °C.

| Standard Glass-Lined Reactor Technical Characteristics | |

| 1.Permissimle Working pressure inside the tank is under 0.2Mpa When the agitator shaft stuffing sealde. 2.The Speed of Frame agitator (above 3000L) is no more than 63r/min. | |

| Permissible Working Pressure PN | Tank inside≤0.37MPa; IN jacket≤0.58 MPa |

| Permissible Working Temperature | Tank inside 0-200℃; IN jacket 0-200℃ |

| Permissible Speed of Agitator | Anchor、Frame63、80 r/min; Impller/Paddle≤125r/ min |

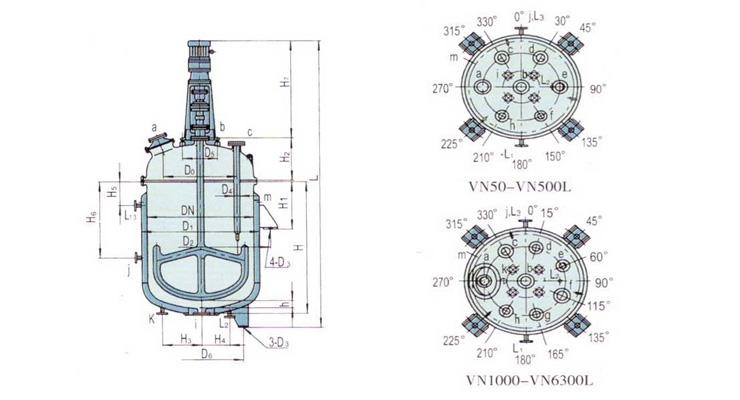

| Dimension Table(79)mm | |||||||||||||

| Designation | Nominal Volume VN (L) | ||||||||||||

| 50 | 100 | 200 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 5000(B) | 5000(A) | 6300 | ||

| DN | 50 | 600 | 700 | 800 | 900 | 1200 | 1300 | 1300 | 1600 | 1600 | 1750 | 1750 | |

| D0 | 350 | 420 | 490 | 560 | 630 | 840 | 910 | 910 | 1120 | 1120 | 1200 | 1200 | |

| D1 | 600 | 700 | 800 | 900 | 1000 | 1300 | 1450 | 1450 | 1750 | 1750 | 1900 | 1900 | |

| D2 | 706 | 816 | 930 | 1106 | 1156 | 1488 | 1679 | 1679 | 2029 | 2045 | 2180 | 2180 | |

| D3 | 25 | 25 | 25 | 25 | 25 | 30 | 30 | 30 | 36 | 36(30) | 36(30) | 36(30) | |

| D4 | 32×4 | 32×4 | 32×4 | 32×4 | 32×4 | 65×5 | 65×5 | 65×5 | 65×5 | 65×8 | 80×6 | 80×6 | |

| D5 | 270 | 270 | 300 | 350 | 350 | 400 | 400 | 400 | 450 | 450 | 450 | 450 | |

| D6 | - | - | - | - | - | 1120 | 1270 | 1270 | 1550 | 1300 | 1400 | 1400 | |

| H | 465 | 565 | 775 | 875 | 1075 | 1275 | 1475 | 1820 | 1820 | 2700 | 2500 | 3025 | |

| H1 | 300 | 300 | 350 | 450 | 400 | 500 | 600 | 600 | 700 | 800 | 700 | 740 | |

| H2 | 265 | 300 | 350 | 385 | 410 | 490 | 510 | 510 | 580 | 610 | 640 | 640 | |

| H3 | 250 | 250 | 250 | 250 | 270 | 315 | 507 | 507 | 614 | 615 | 550 | 550 | |

| H4 | - | - | - | - | - | - | 315 | 315 | 315 | 315 | 350 | 350 | |

| H5 | - | - | - | - | - | - | 330 | 330 | 330 | 330 | 370 | 370 | |

| H6 | 220 | 220 | 230 | 240 | 270 | 270 | 1000 | 1335 | 1247 | 1750 | 1530 | 1760 | |

| H7 | 945 | 945 | 953 | 1154 | 1154 | 1276 | 1276 | 1276 | 1316 | 1316 | 1316 | 1451 | |

| L | 2030 | 2170 | 2430 | 2782 | 3040 | 3430 | 3670 | 4010 | 4235 | 5100 | 4955 | 5190 | |

| h | Turbine | 95 | 100 | 105 | 125 | 165 | 180 | 165 | 175 | 190 | 140 | 140 | 190 |

| Anchor/Frame | 45/- | 60/- | 45/- | 85/- | -/85 | -/110 | -/115 | -/125 | -/144 | 240 | 270 | 270 | |

| Clamp | 0.2Mpa | M16/28 | M16/28 | M16/36 | M16/40 | M20/32 | M20/52 | M20/56 | M20/56 | M24/52 | BM24/60 | BM24/68 | BM24/68 |

| 0.4 Mpa | M16/28 | M16/32 | M16/40 | M16/48 | M20/36 | M20/56 | M20/70 | M20/64 | M24/60 | BM24/68 | BM24/76 | BM24/76 | |

| Reducer Ttpe | BLD0.8-1-i | BLD0.8-1-i | BLD1.1-1-i | BLD3.0-3-i | BLD3.0-3-i | BLD4-3-i | BLD4-3-i | BLD4-3-i | BLD5.5-3-i | BLD | BLD | BLD | |

| Discharge Valve Specifcation | 70/32 | 70/32 | 80/40 | 80/40 | 80/40 | 100/50 | 100/50 | 100/50 | 125/80 | 125/80 | 125/80 | 125/80 | |

| Motor Power | 0.8 | 0.8 | 1.1 | 3 | 3 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 | 7.5(5.5) | |

| Actual Valume | 71 | 128 | 247 | 389 | 588 | 1250 | 1720 | 2160 | 3715 | 5730 | 5930 | 7250 | |

| Heat Transfer Area | 0.34 | 0.66 | 1.26 | 1.75 | 2.64 | 4.54 | 5.34 | 7.02 | 8.61 | 13.57 | 12.58 | 15.6 | |

| Total Weight | 477 | 548 | 706 | 975 | 1052 | 1657 | 2051 | 2170 | 3833 | 4440 | 4520 | 5090 | |

| Nozzle Specification and Service(79)mm | |||||||||||||

| Nominal Volume VN (L) | Designation (DN) | ||||||||||||

| a Hand/Man Hole | b Agitating Hole | c Themometer Hole | d Spare Hole | e Spare Hole | f Spare Hole | g Spare Hole | h Spare Hole | i Discharging Hole | k Inlet(Outet) Hole | m Exhaust Hole | L1、2、3 Inlet(Outet) Hole | J Inlet(Outet) Hole | |

| 50 | 80 | 65 | 65 | 65 | 65 | 65 | - | - | 65 | 20 | M10 | - | 20 |

| 100 | 80 | 65 | 65 | 65 | 65 | 65 | - | - | 65 | 20 | M10 | - | 20 |

| 200 | 125 | 80 | 65 | 65 | 80 | 65 | - | 65 | 80 | 25 | M10 | - | 25 |

| 300 | 125 | 100 | 65 | 65 | 80 | 65 | - | 65 | 80 | 25 | M10 | - | 25 |

| 500 | 150 | 100 | 65 | 65 | 100 | 125 | - | 80 | 80 | 32 | M10 | - | 32 |

| 1000 | 300×400 | 125 | 100 | 100 | 100 | 125 | 100 | 100 | 100 | 32 | M10 | - | 32 |

| 1500 | 300×400 | 125 | 100 | 100 | 125 | 125 | 100 | 125 | 100 | 50 | M10 | 40 | 50 |

| 2000 | 300×400 | 125 | 100 | 100 | 125 | 125 | 100 | 125 | 100 | 50 | M10 | 40 | 50 |

| 3000 5000(B) | 300×400 | 125 | 100 | 100 | 125 | 125 | 100 | 125 | 125 | 65 | M10 | 50 | 65 |

| 5000(A) | 300×400 | 125 | 100 | 125 | 125 | 150 | 125 | 150 | 125 | 65 | M10 | 65 | 65 |

| 6300 | 300×400 | 125 | 125 | 125 | 125 | 150 | 125 | 150 | 125 | 65 | M10 | 65 | 65 |

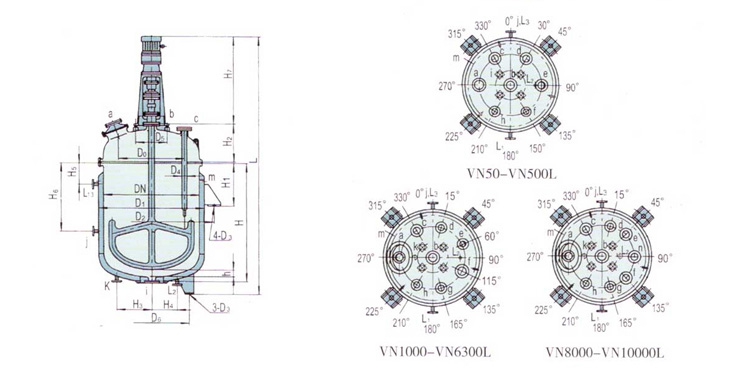

| Standard Glass-Lined Reactor Technical Characteristics | |

| Permissimle Working pressure inside the tank is under 0.2Mpa When the agitator shaft stuffing sealde. The Speed of Frame agitator (≥3000L) is no more than 65r/min | |

| Permissible Working Pressure PN | Tank inside≤0.37MPa; IN jacket≤0.58 MPa |

| Permissible Working Temperature | Tank inside 0-200℃; IN jacket 0-200℃ |

| Permissible Speed of Agitator | Anchor、Frame63、85 r/min; Impller/Paddle≤125r/ min |

| Dimension Table(93)mm | ||||||||||||||

| Designation | Nominal Volume VN(L) | |||||||||||||

| 50 | 100 | 200 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000(B) | 5000(A) | 6300 | ||

| DN | 500 | 600 | 700 | 800 | 900 | 1200 | 1300 | 1300 | 1600 | 1600 | 1600 | 1750 | 1750 | |

| D0 | 350 | 420 | 490 | 560 | 630 | 840 | 910 | 910 | 1120 | 1120 | 1120 | 1120 | 1120 | |

| D1 | 600 | 700 | 800 | 900 | 1000 | 1300 | 1450 | 1450 | 1750 | 1750 | 1750 | 1900 | 1900 | |

| D2 | 726 | 828 | 930 | 1027 | 1152 | 1485 | 1679 | 1679 | 2029 | 2045 | 2045 | 2180 | 2180 | |

| D3 | 25 | 25 | 25 | 25 | 25 | 30(25) | 30(30) | 30(30) | 36(30) | 36 | 36(30) | 36(30) | 36(30) | |

| D4 | 32×4 | 32×4 | 32×4 | 32×4 | 32×4 | 65×5 | 65×5 | 65×5 | 65×6 | 65×8 | 65×8 | 80×6 | 80×6 | |

| D5 | 270 | 270 | 300 | 350 | 350 | 400 | 400 | 400 | 450 | 450 | 450 | 450 | 450 | |

| D6 | - | - | - | - | - | - | 1100 | 1100 | 1300 | - | 1300 | 1400 | 1400 | |

| H | 465 | 565 | 775 | 875 | 1075 | 1275 | 1475 | 1820 | 1820 | 2170 | 2700 | 2500 | 3025 | |

| H1 | 310 | 310 | 350 | 350 | 400 | 500 | 600 | 600 | 700 | 800 | 800 | 700 | 740 | |

| H2 | 265 | 300 | 355 | 385 | 415 | 500 | 530 | 530 | 610 | 610 | 610 | 640 | 640 | |

| H3 | - | - | - | - | - | - | 507 | 507 | 614 | 615 | 615 | 550 | 550 | |

| H4 | 250 | 250 | 250 | 250 | 270 | 315 | 315 | 315 | 315 | 315 | 315 | 350 | 350 | |

| H5 | 220 | 220 | 230 | 240 | 270 | 280 | 330 | 330 | 330 | 330 | 330 | 370 | 370 | |

| H6 | - | - | - | - | - | - | 1000 | 1335 | 1247 | 1050 | 1750 | 1530 | 1760 | |

| H7 | 945 | 945 | 953 | 1154 | 1200 | 1276 | 1276 | 1276 | 1316 | 1316 | 1316 | 1316 | 1451 | |

| L | 2030 | 2170 | 2426 | 2782 | 3040 | 3470 | 3695 | 4035 | 4225 | 4660 | 5100 | 4955 | 5190 | |

| h | Anchor/Frame | 45 | 60 | 60 | 85 | 80 | 100 | 110 | 110 | 140 | - | 140 | 140 | 190 |

| Paddle/lmpller | 90 | 110 | 130 | 150 | 160 | 210 | 210 | 210 | 240 | 240 | 240 | 270 | 270 | |

| Clamp | 0.25Mpa | BM16/16 | BM16/28 | BM16/36 | BM16/40 | BM20/36 | BM20/52 | BM20/56 | BM20/56 | BM24/60 | BM20/60 | BM24/60 | BM24/68 | BM24/68 |

| 0.6 Mpa | BM16/28 | BM16/36 | BM16/41 | BM16/48 | BM20/40 | BM20/56 | BM20/70 | BM20/70 | BM24/68 | BM24/68 | BM24/68 | BM24/76 | BM24/76 | |

| Reducer Ttpe | BLD | BLD | BLD | BLD | BLD | BLD | BLD | BLD | BLD | BLD | BLD | BLD | BLD | |

| Discharge Valve Specifcation | 65/32 | 65/32 | 80/40 | 80/40 | 80/40 | 100/50 | 100/50 | 100/50 | 125/80 | 125/80 | 125/80 | 125/80 | 125/80 | |

| (kw) Motor Power | 0.8 | 0.8 | 1.1 | 3 | 3 | 4.0 | 4.0 | 4 | 5.5 | 5.5 | 5.5 | 5.5 | 7.5(5.5) | |

| (L) Actual Valume | 71 | 128 | 247 | 389 | 588 | 1250 | 1720 | 2160 | 3715 | 4730 | 5730 | 5930 | 7250 | |

| (m2) Heat Transfer Area | 0.34 | 0.66 | 1.26 | 1.75 | 2.64 | 4.54 | 5.34 | 7.02 | 8.61 | 11.01 | 13.57 | 12.58 | 15.6 | |

| (kg) Total Weight | 440 | 482 | 707 | 765 | 1030 | 1690 | 2160 | 2410 | 3450 | 3880 | 4440 | 4520 | 5090 | |

| Nozzle Specification and Service (93)mm | |||||||||||||

| Nominal Volume VN(L) | Designation (DN) | ||||||||||||

| a Hand/Man Hole | b Agitating Hole | c Themometer Hole | d Spare Hole | e Spare Hole | f Spare Hole | g Spare Hole | h Spare Hole | i Discharging Hole | j Inlet(Outet) Hole | m Exhaust Hole | L1、2、3 Inlet(Outet) Hole | k Inlet(Outet) Hole | |

| 50 | 80 | 65 | 65 | - | 65 | 65 | - | - | 65 | - | M10 | 20 | - |

| 100 | 80 | 65 | 65 | - | 65 | 65 | - | - | 65 | - | 20 | - | |

| 200 | 125 | 80 | 65 | 65 | 80 | 65 | - | 65 | 80 | - | 25 | - | |

| 300 | 125 | 100 | 65 | 65 | 80 | 65 | - | 65 | 80 | - | 25 | - | |

| 500 | 150 | 100 | 65 | 80 | 100 | 125 | - | 80 | 80 | - | 32 | - | |

| 1000 | 300×400 | 125 | 100 | 100 | 100 | 125 | 100 | 100 | 100 | - | 32 | - | |

| 1500 | 300×400 | 125 | 100 | 100 | 125 | 125 | 100 | 125 | 100 | 40 | 40 | 40 | |

| 2000 | 300×400 | 125 | 100 | 100 | 125 | 125 | 100 | 125 | 100 | 50 | 40 | 50 | |

| 4000 | 300×400 | 150 | 100 | 125 | 125 | 125 | 100 | 125 | 125 | 65 | 65 | 65 | |

| 3000 5000(B) | 300×400 | 150 | 100 | 100 | 125 | 125 | 100 | 125 | 100 | 65 | 50 | 65 | |

| 5000(A) | 300×400 | 150 | 125 | 125 | 125 | 150 | 125 | 150 | 125 | 65 | 65 | 65 | |

| 6300 | 300×400 | 150 | 125 | 125 | 125 | 150 | 125 | 150 | 125 | 65 | 65 | 65 | |

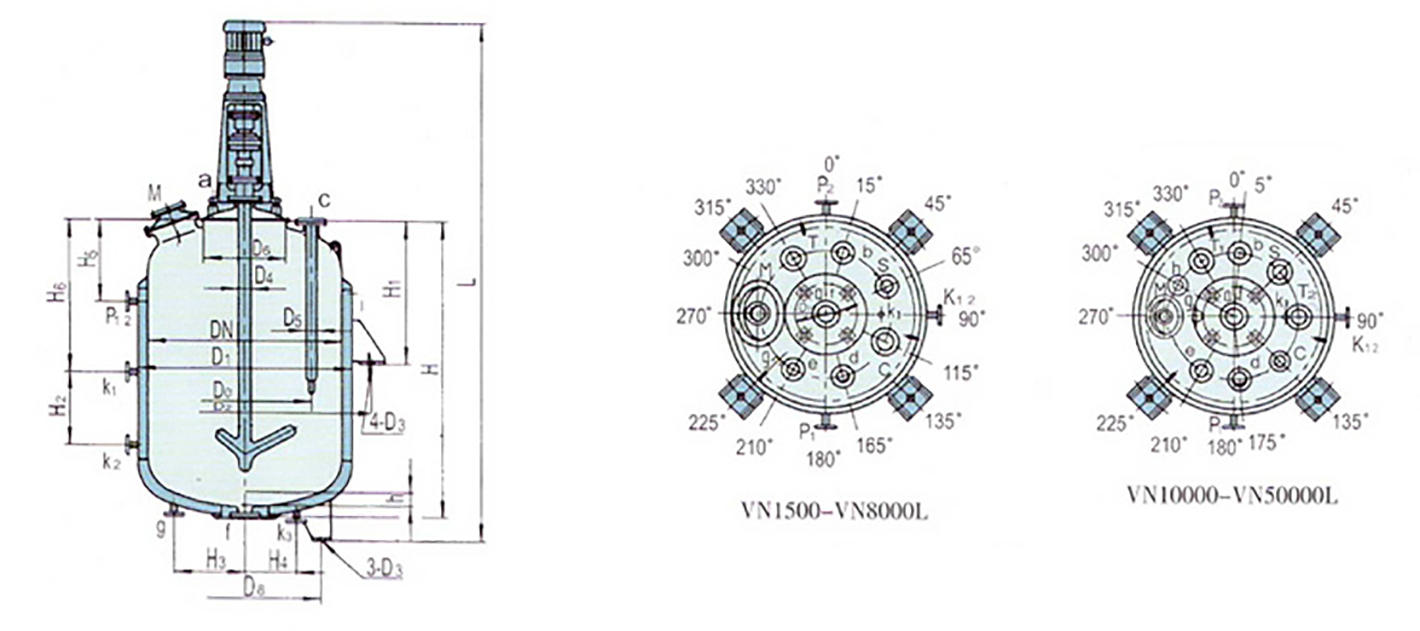

| Dimension Table (mm) | ||||||||||||||||||||

| Nominal Volume VN(L) | Designation | Weight(kg) | ||||||||||||||||||

| DN | D0 | D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | H | H1 | H2 | H3 | H4 | H5 | H6 | h | L | ||

| 1500 | 1300 | 910 | 1450 | 1679 | 30 | φ80 | 65×5 | 500 | 400 | - | 1670 | 975 | - | 315 | 507 | 700 | 1070 | 240 | 3360 | 1830 |

| 2000 | 1300 | 910 | 1450 | 1679 | 30 | φ80 | 65×5 | 500 | 400 | - | 2040 | 975 | - | 315 | 507 | 700 | 1415 | 240 | 3730 | 2155 |

| 3000 | 1600 | 1120 | 1750 | 2029 | 36 | φ95 | 65×6 | 600 | 450 | 1300 | 2130 | 1160 | - | 315 | 515 | 780 | 1710 | 240 | 3740 | 3010 |

| 4000 | 1600 | 1120 | 1750 | 2029 | 36 | φ95 | 80×6 | 600 | 450 | - | 2705 | 1160 | - | 315 | 515 | 780 | 1240 | 240 | 4230 | 3487 |

| 5000 | 1600 | 1120 | 1750 | 2029 | 36 | φ95 | 80×6 | 600 | 450 | 1300 | 3120 | 1160 | - | 315 | 515 | 780 | 1745 | 240 | 4730 | 4210 |

| 5000 | 1750 | 1200 | 1900 | 2200 | 36 | φ95 | 80×6 | 600 | 450 | 1400 | 2770 | 1200 | 420 | 350 | 550 | 886 | 1656 | 270 | 4380 | 4060 |

| 6300 | 1750 | 1200 | 1900 | 2200 | 36 | φ95 | 80×6 | 600 | 450 | 1400 | 3280 | 1220 | 900 | 350 | 550 | 885 | 1785 | 270 | 5040 | 4950 |

| 8000 | 2000 | 1400 | 2200 | 2502 | 36 | φ95 | 95×8 | 800 | 500 | 1600 | 3250 | 1360 | 690 | 400 | 510 | 960 | 1860 | 330 | 5180 | 6455 |

| 10000 | 2200 | 1640 | 2400 | 2734 | 36 | φ110 | 95×8 | 800 | 550 | 1700 | 3460 | 1460 | 900 | 470 | 660 | 1020 | 1920 | 360 | 7058 | 8775 |

| 10000 | 2400 | 1680 | 2600 | 2940 | 36 | φ110 | 95×8 | 800/1450 | 550 | 1800 | 3080 | 1500 | 640 | 470 | 550 | 1010 | 1610 | 360 | 5910 | 9931 |

| 12500 | 2400 | 1680 | 2600 | 2940 | 36 | φ140 | 95×8 | 800/1450 | 550 | 1800 | 3575 | 1500 | 900 | 470 | 550 | 1040 | 1940 | 360 | 6400 | 11950 |

| 15000 | 2400 | 1220 | 2600 | 2940 | 36 | φ125 | 95×8 | 900/1600 | 550 | 2000 | 4100 | 1400 | 1500 | 470 | 550 | 1100 | 1940 | 360 | 7850 | 11335 |

| 20000 | 2600 | 1220 | 2800 | 3181 | 36 | φ140 | 95×8 | 900/1750 | 550 | 2000 | 4640 | 1530 | 1300 | 470 | 550 | 1000 | 2200 | 300 | 9100 | 14500 |

| 30000 | 2800 | 1220 | 3000 | 3380 | 36 | φ140 | 95×8 | 1750 | 550 | 2200 | 5510 | 1600 | 1300 | 470 | 550 | 1000 | 2200 | 360 | 9960 | 21950 |

| 40000 | 3200 | 1360 | 3400 | - | 24 | φ160 | 110×12 | 1900 | 810 | 2250 | 6000 | - | 1500 | 470 | 550 | 1220 | 2720 | 400 | 10305 | 28320 |

| 50000 | 3400 | 1500 | 3600 | 4378 | 36 | φ180 | 125×12 | 2000 | 940 | - | 6765 | 2200 | 1700 | 470 | 550 | 1250 | 2950 | 400 | 10565 | 34175 |

| Nozzle Specification and Service (mm) | ||||||||||||||||

| Nominal Volume VN(L) | Designation | |||||||||||||||

| DN | a Agitating Hole | b Spare Hole | c Spare Hole | d Spare Hole | e Spare Hole | f Discharging Hole | g Inlet(Outet) Hole | h Spare Hole | m Man Hole | s Lamp Hole | T1 Temperature MeasureHole | T2 Spare Hole | p1-2 LiquidIniet (Outet)Hole | k1-3 Iniet (Outet)Hole | i Exhaust Hole | |

| 1500 | 1300 | 125 | 100 | 125 | 125 | 100 | 100 | 50 | - | - | 125 | 100 | - | 40 | 50 | M10 |

| 2000 | 1300 | 125 | 100 | 125 | 100 | 125 | 100 | 50 | - | - | 125 | 100 | - | 40 | 50 | |

| 3000 | 1600 | 150 | 100 | 125 | 100 | 125 | 125 | 65 | - | 300×400 | 125 | 100 | - | 65 | 65 | |

| 4000 | 1600 | 150 | 100 | 200 | 100 | 125 | 125 | 65 | - | 300×400 | 125 | 100 | - | 65 | 65 | |

| 5000 | 1600 | 150 | 100 | 125 | 100 | 125 | 125 | 65 | - | 300×400 | 125 | 100 | - | 65 | 65 | |

| 5000 | 1750 | 150 | 125 | 150 | 125 | 150 | 125 | 65 | - | 300×400 | 125 | 125 | - | 65 | 65 | |

| 6300 | 1750 | 150 | 125 | 150 | 125 | 150 | 125 | 65 | - | 300×400 | 125 | 125 | - | 65 | 65 | |

| 8000 | 2000 | 150 | 150 | 150 | 150 | 150 | 125 | 65 | - | 300×400 | 125 | 150 | 125 | 80 | 65 | |

| 10000 | 2200 | 200 | 150 | 150 | 150 | 125 | 150 | 80 | 125 | 300×400 | 125 | 200 | 125 | 80 | 80 | |

| 10000 | 2400 | 200 | 150 | 150 | 125 | 125 | 150 | 80 | 125 | 300×400 | 125 | 200 | 125 | 80 | 80 | |

| 12500 | 2400 | 250 | 150 | 150 | 150 | 125 | 150 | 80 | 125 | 300×400 | 125 | 200 | 125 | 80 | 80 | |

| 15000 | 2400 | 200 | 150 | 150 | 150 | 150 | 150 | 100 | 200 | 300×400 | 125 | 200 | 125 | 100 | 100 | |

| 20000 | 2600 | 250 | 150 | 150 | 150 | 150 | 150 | 100 | 200 | 450 | 125 | 200 | 125 | 100 | 100 | |

| 30000 | 2800 | 250 | 150 | 150 | 150 | 150 | 150 | 100 | - | 450 | 125 | 200 | 125 | 100 | 100 | M10 |

| 40000 | 3200 | 250 | 150 | 150 | 150 | 150 | 150 | 100 | - | 300×400 | 125 | 250 | - | 100 | 100 | |

| 50000 | 3400 | 250 | 150 | 150 | 250 | 150 | 200 | 100 | - | 300×400 | 125 | 250 | 150 | 100 | 100 | |

Water Reducer

Water Reducer

Welcome to contact us for more details& any questions:

Luohe Tianheng Machinery Co., Ltd is established in 2014 and specialized in manufacturering the

industrial mixer machine series and intelligent automatic packaging equipment. Company is located

in Luohe City, Henan Province, our advantage is offer client the whole producing line machines: automatic

loading conveying, quick effective mixture processing, automatic quantitative filling and packaging ect.

We have our own technical search & development department team, we offer client satisfactory after-sale

service, also the coming consumer's factory service is available.

We have large quantity business around the world in our export, We have exported our machines to

many countries and areas around, such as the USA, Colombia, Ecuador, Uzbekistan, Sri Lanka and Africa

market. Coming visit our company is welcome !

Welcome your inquire!

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist