PVA Emulsions Plant

Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery durable chemical reaction machine manufacturer for chemical industry

- Jinzong provides practical services based on different customer demand.

1. Jinzong Machinery high temperature reactor is manufactured with high precision in order to meet the set industry standards.

2. The product is precise and reusable. It ensures that its tasks are completed every time in accordance with standard specifications and procedures.

3. The product has high rigidity. Its metal materials have the ability to withstand elastic deformation when applied with pressure.

4. It brings considerable profitability and brand influence to Jinzong Machinery.

5. The product is applicable with high efficiency.

The reactor is widely used for reaction, evaporation, concentration, synthesization, extraction, polymerization, mineralization, etc.in chemical industry, medicine, dye, pesticide, organic synthesis, petroleum, food additives, industry of national defense and scientific research. Our company is an enterprise specialized in designing and manufacturing reaction kettles. With twenty years of experience in manufacturing reaction kettles, we can design and manufacture various types of reaction kettles for users.

*Product Function Brief:

A. Operating principle: Break down or recombined the materials through mixing, filling and cooling, to promote the reaction of polymerization.

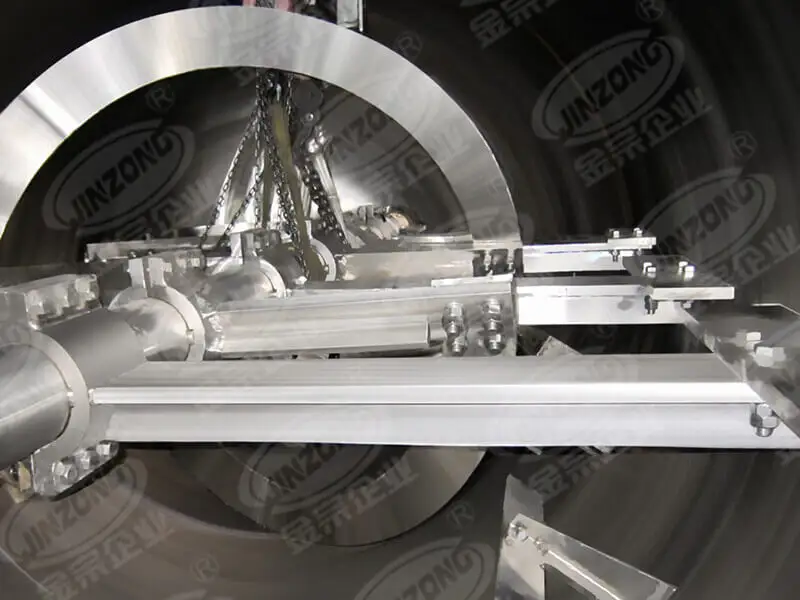

B. Components: Body, gears, mixing devices, heating devices, cooling devices, seal, etc.

C. Auxiliary Equipment: Distillation column, head tank, condenser, water separator, collecting cans, filters, etc.

D. Widely used in: Resins, adhesives, paint, cosmetics, pharmaceutical and other chemical production.

E. Applicable Field: All the liquid-liquid, liquid-powder reaction industry.

| Composition | Instruction |

| Capacity | 50L-50T |

| Heating Method | Steam heating, electrical heating, conduction oil heating by jacket |

| Cooling method | Water cooling, conduction oil cooling by inner coil or jacket |

| Design Pressure Mpa | Atmospheric pressure or under pressure or pressure tank |

| Blending Power | Model selection is made according to material viscosity, liquid—solid ration, liquid specific gravity, solid specific gravity, solid granularity, rotation speed, paddle type, with or without baffle or internal coil |

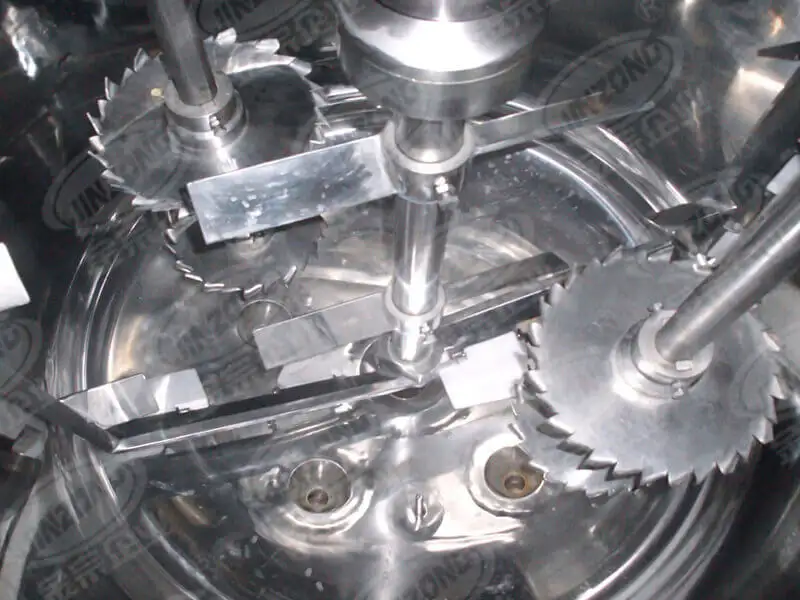

| Stirring Blade Forms | Anchor type, frame type, flat paddle type, pitched paddle type, ribbon type, turbo type, pusher type and multiple compound type |

| Seal | Mechanical seal or stuff packing seal |

| Inner Surface Treatment | Polished or no polished |

| Discharge Valve | Flanged ball valve, open downward discharge valve and others |

| Technological Pipe Hole | Manhole, sight glass, distillation mouth, imported materials, pressure gauge port, temperature mouth, mouth filling N2, a gate, hot-carrier import and export of the cooling fluid, temperature measurement ports, sampling ports, emptying the mouth, according to the process above requirements increase or decrease. |

Mixing system is the core component of reactor, a custom-made stirrer is your key to success. Stirrer selection is related with the material’s viscosity, liquid-solid ratio, proportion of liquid, solid’s weight, solid’s particle size, blade type, rotating speed, baffle, internal pipe coil etc.

| Specifications (L) | Cylinder size (mm) | Actual volume (L) | Jacket volume (L) | Heating area (㎡) | Motor Power (kw) | Speed (r/min) | Discharge valve |

| 50 | 450*450 | 61 | 65 | 0.78 | 0.55 | 85 | DN25 |

| 100 | 450*500 | 150 | 120 | 1.36 | 1.1 | 85 | DN25 |

| 200 | 600*700 | 253 | 200 | 1.9 | 1.5 | 85 | DN40 |

| 300 | 750*750 | 396 | 250 | 2.41 | 2.2 | 85 | DN40 |

| 500 | 900*800 | 699 | 290 | 2.7 | 3 | 85 | DN50 |

| 1000 | 1200*1000 | 1393 | 560 | 4.5 | 4 | 85 | DN50 |

| 1500 | 1300*1200 | 2166 | 617 | 5.9 | 5.5 | 85 | DN50 |

| 2000 | 1400*1500 | 3000 | 750 | 7 | 5.5 | 85 | DN65 |

| 3000 | 1600*1500 | 4066 | 1050 | 9 | 7.5 | 63 | DN65 |

| 4000 | 1700*1800 | 5400 | 1226 | 11 | 11 | 63 | DN80 |

| 5000 | 1800*2000 | 6600 | 1440 | 12.8 | 11 | 63 | DN80 |

*Application of Reaction plant:

The whole set of equipment includes reactor, vertical fractionating column, horizontal condenser, water storage tank, oil spill tank and piping (dilution kettle). All parts of the equipment that contact with the material are all made by stainless steel.

*Model selection reference of resin production equipment:

| Composition | Instructions |

| Main Reactor | The size, material, heat transfer systems, mixing systems, sealing systems of reactor according to client's specification |

| Dosing Vessel | According to the client's demand, it adopts gravity tank, gravity mixing tank, gravity dispersing tank, gravity emulsifying tank. |

| Distillation Device | Vertical condenser, horizontal condenser and separator. |

| Vacuum system | All kinds of vacuum pumps, buffer tanks. |

| Thinning Vessel/cooling tank | The size, material, heat transfer systems, mixing systems, sealing systems of thinning vessel according to client's specification |

| Pipeline system | According to the client's demand, it decides the heating, cooling, vacuum and material pipelines, and including related valves, flowmeters and expanders etc. |

| Control System | According to client's demand, it decides manual, semi-automatic or full-automatic system. |

| Filter System | Frame filter, bag filter or centrifuge etc. |

| Operation Platform | Steel platform or concrete platform |

Ink Production

Insulation Paint Production

Resin Production

We carry out products designing, manufacturing, assembling and detection fully in accordance with ISO9001-2015 Quality Management System issued by Swiss SGS Company.

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. is a creator, engineer, and problem solver. We are passionate about the R&D and manufacture of high temperature reactor .

2. We always believe that our R&D team contributes significantly to the sustainability of our business. Their abundant knowledge and experience about the products, industry, and clear foresight about future problems or market trends has proved of importance for us.

3. We are committed to conducting our business in a way that minimizes adverse impact on the environment. We limit the environmental impact of our day-to-day operations by improving energy efficiency and reducing greenhouse gas emissions. We think highly of environmental protection and resource conservation. During our production, we try to minimize our pollution by adopting energy-saving technology. We build up a strong company culture of society charity while maintaining profitable growth in business. We regularly hold or take part in all kinds of donation projects or charity sells. In every stage of our operation, we constantly maintain strict environmental and sustainability standards to minimize our production waste and pollution.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)