Company Advantages1. The raw material of

Jinzong Machinery goes through a rigorous selection procedure. The product has the merit of full traceability

2. This product has many advantages, has won a good reputation in the market, and has broad market potential. It has a compact design, occupying less space

3. This product features high efficiency. It is able to bring out the desired outcomes in the fastest manner without any errors. It is resistant to breakage with its sturdy frame

4. The product features a rugged industrial-strength frame. It mainly adopts hot-rolled steel and wrought materials such as stainless steel materials for better resistance to impacts. The product is very easy to maintain

5. It is highly accurate when it operates. With a precise control system, it can work flawlessly and consistently under the given instructions. The product can be used in harsh industrial environments

*DEFINITION OF Customized Stainless steel storage tank pressure vessels:

Stainless steel storage tanks are used to store liquids for the beverage, chemical, cosmetic, dairy, food and pharmaceutical industries. Stainless steel tanks can be cylindrical or rectangular, vertical or horizontal, open top or closed top, flat bottom or dished bottom supported by legs. Stainless storage tanks are a popular choice for many manufacturing processes due to their durability and corrosion resistance in comparison to steel tanks. Stainless steel tanks can be constructed from different grades of stainless steel. The grade of stainless will often be determined by the product being stored. Products with a higher crossiveness will often require a higher grade of stainless to prevent any erosion of the tank over time.

Material:SS304, 304L, 316 or SS316L

Design Pressure:-1 -10 Bar (g) or ATM

Work Temperature:0-200 °C

Volumes:5~30000L, customized

We can supply single-layer, double-layer and three-layer stainless steel storage tanks.

As the tanks can be used for a number of different applications, there a wide range of specific types and components that a customer can choose from. Stainless tanks can be positioned as either horizontal or vertical, depending both on the loading and unloading method of the operation, and also the properties and use of the substance contained within the tank. They can also be flat bottomed or cone bottomed, cylindrical, square or spherical as well as single walled or double walled. The stainless steel vessels which are combined with hydraulic pressure are typically cylindrical in order to be able to endure the stress of the liquid or gas and pressure. Other features which may or may not be included with a custom storage tank include sight gauges to determine product level, exterior ladders, tank covers, ducting and pumps, instrumentation, exhaust systems and scrubbers. These may or may not be necessary depending on the intended application and location of the tank and the engineers will determine how much additional equipment is required in order to achieve the best storage solution.

If you have any technical requirement,feel free let us know . We can design the tanks according to your requirement .

*Stainless steel storage tank performances and features:

◪ Design compliance with cGMP.

◪ Multiple Sizes and Styles;

◪ Atmospheric, Vacuum or Pressure Operation;

◪ Corrosion resistance: Stainless steel is highly resistant to corrosion, which means that it does not rust or corrode easily. This makes it an ideal material for storing liquids and chemicals that may be corrosive.

◪ Durability: Stainless steel is a very durable and strong material that can withstand high temperatures and pressures. It is also resistant to scratches, making it less likely to be damaged during handling and transportation.

◪ Aesthetic appeal: Stainless steel has a sleek and modern appearance that can enhance the overall aesthetic appeal of a facility or production line. It is also available in a variety of finishes and textures, allowing it to be customized to suit specific applications and design requirements.

◪ Hygiene and cleanliness: Because stainless steel is a non-porous material, it does not absorb bacteria or other microorganisms. This allows it to be easily cleaned and sanitized, keeping the contents safe and contaminant-free.

Overall, custom stainless steel tanks are an excellent choice for a wide range of industrial, commercial, and residential applications, offering superior durability, hygiene, and aesthetic appeal.

When choosing stainless steel tanks, there are several factors that you should consider to make the right choice:

Type of Stainless Steel: There are different types of stainless steel available, each with its own characteristics. The most commonly used grades are 304 and 316. 304 is suitable for most applications, while 316 is preferred for more corrosive environments.

Thickness: The thickness of the stainless steel used in the tank will affect its overall strength and durability. A thicker tank will be stronger and less likely to dent or deform.

Welding Quality: The quality of welding on the tank can affect its strength and durability. Make sure to choose a manufacturer who has a reputation for high-quality welding.

Surface Finish: The surface finish of the tank has a significant impact on its ease of cleaning, sanitation, and overall appearance. Choose a finish that suits your needs.

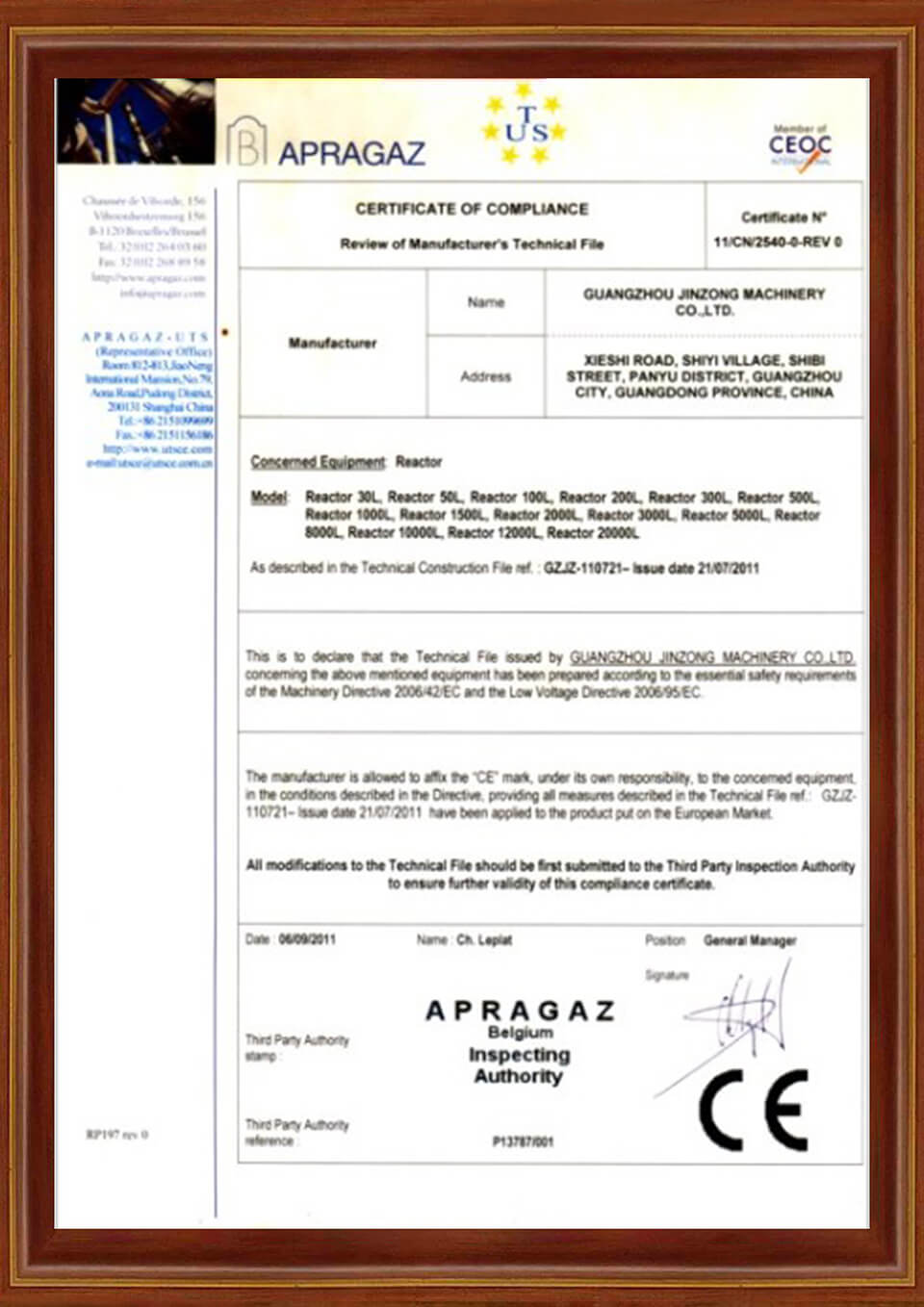

Certification: Ensure the tanks have been certified by a reputable agency according to applicable standards, such as ASME, FDA, or other industry-specific certifications.

To select the right stainless steel tank for your specific requirements, you should work with a trusted stainless steel storage tank factory & supplier.

*Stainless steel storage tank:

Jinzong machinery stainless steel storage tank is widely used in chemical, pharmaceutical, dye, pesticide, organic synthesis, petroleum, food additives, defense industry and scientific research.

Company Features1. Relying on the core strength in manufacturing , Guangdong Jinzong Machinery Co., Ltd. has already stepped far ahead in the market.

2. We own a team of designers with years of experience. They have attention to detail and commitment to perfection, which allows us to provide the highest quality products per to customers' specifications.

3. The quality of the service has been highly stressed by Jinzong Machinery. Ask!