Our Glass lined reactor Enamel reaction kettle are all fired with a specific specification electric furnace. Enamel/glass enameled equipment has smooth surface, wear resistance, heat resistance, easy washing, non-polluting materials, low price, and not easy porcelain.

Enamels and enamels are only different in name, and there is actually no essential difference. Specially speaking, enamels are low-temperature enamels(690-780 °C), and enamels are high-temperature enamels(880-1050 °C). The melting temperature of the steel plate is 1300 °C.

*DEFINITION OF Glass lined reactor Enamel reaction kettle:

The enamel/enamelled glass reaction kettle(reaction tank) is a chemical equipment that enamels glass enamels containing high silicon dioxide and is lined on the inner surface of a steel container, and is then evenly bonded to the metal surface by burning at high temperatures. Therefore, the enamel reaction kettle has the dual advantages of glass stability and metal strength, and is an excellent corrosion resistant chemical equipment. The enamel reaction kettle(enamel reaction tank) is widely used for reaction, evaporation, concentration and synthesis in industrial production and scientific research such as chemical industry, medicine, dyes, pesticides, organic synthesis, petroleum, food manufacturing and defense industry. , extraction, polymerization, saponification, mineralization, chlorination, nitrification, etc. to replace expensive stainless steel and non-ferrous metals.

Reactor kettles, also known as reaction tanks, distillation tanks, water bath kettles, neutralization kettles, dissolution kettles, condensation kettles, and many other names are named based on the chemical reactions of their own products.

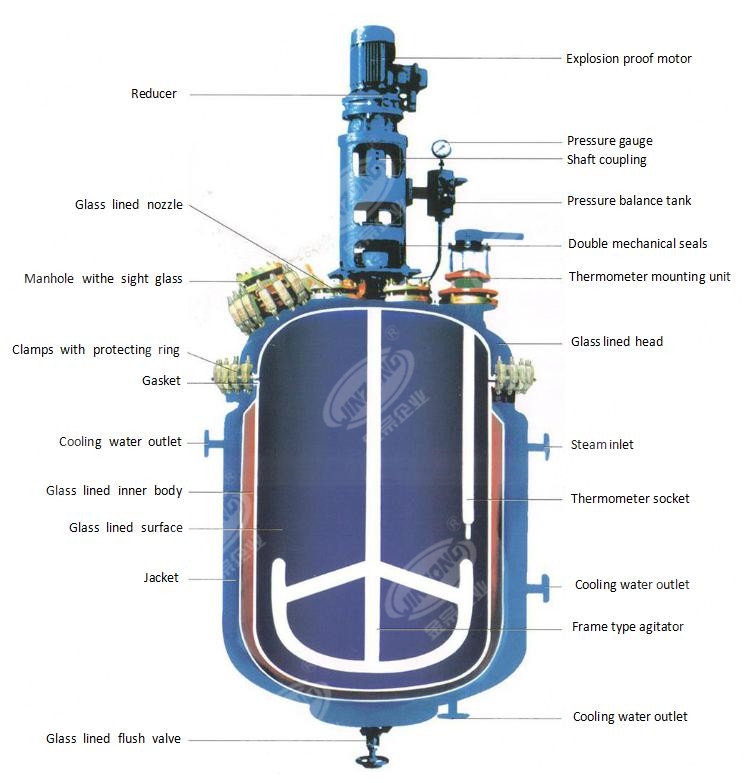

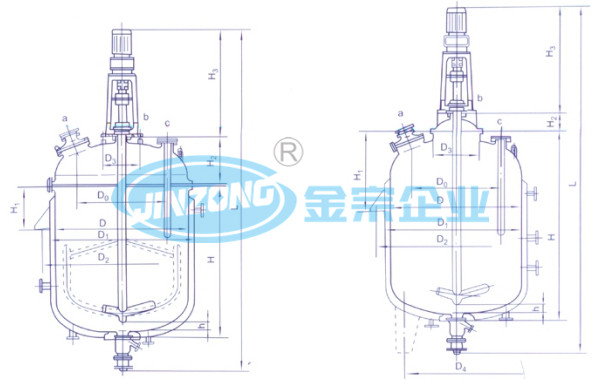

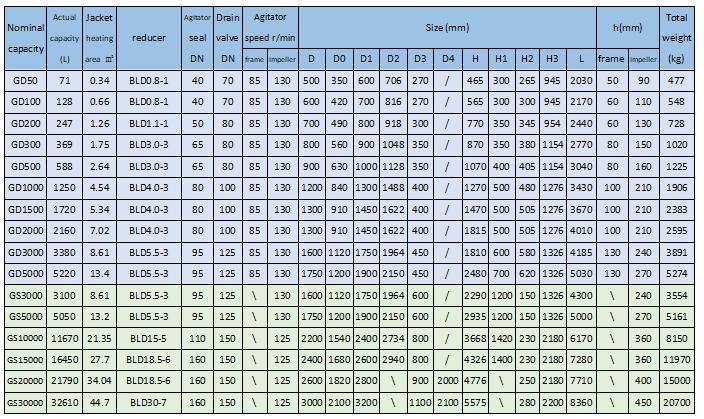

*MAIN COMPOSITION of Glass lined reactor Enamel reaction kettle:

The glass lined reactor enamel reaction kettle is mainly composed of tank body, insulation material and accessories. The tank body includes inner cylinder, outer cylinder, jacket and supporting foot, etc. Rock wool filling is used as insulation layer between inner cylinder and outer cylinder, jacket form is integrate jacket.

The accessories mainly include sanitary manhole, mirror, light, material and liquid inlet and outlet pipe, thermometer, pressure gauge, etc..

*Glass lined reactor Enamel reaction kettle performances and features:

◪ Voltage resistance: the glass lined has very good insulating property. working area does not conduct when testing with 20KV high frequency voltage.

◪ Corrosion proof: organic or inorganic acid, organic solvent and weak alkaline corrosion can be endured except hydrofluoric acid, media containing fluorine ion, oil of vitriol and alkali with their denisty over 30% and temperature higher than 180°C;

◪ Nonstick: with the smooth and nonstick surface, they are very suitable for food industry and adhesive material process;

*Glass lined reactor Enamel reaction kettle:

Glass-lined reactor is widely used in reaction, evaporation, concertration, composition, extraction, saponification, mineralization, chlorination, nitration etc. Of chemical, pharmaceutical, dye, pesticide, organic synthesis, petroleum, food additives, defense industry and scientific research. Corrosion resistance: It resists all kinds of thickness of mediums like inorganic acid, organic acid, organic solvent and weak base etc. But it isn't suitable for strong base, hydrofluoric acid, fluorion medium, phosphoric acid whose temperature is over 180 degree and thickness is over 30% etc.

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist