Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery custom chocolate coating machine factory for reaction

Company Advantages

1. We work with the best materials sourced from across the globe to give that extra lift to chocolate coating machine 's quality. The product has an alert function for fault detection

2. This product only requires a low number of workers, which helps save labor costs. This will finally help business owners achieve a competitive advantage. The product has the advantage of low energy consumption

3. The product has been tested to be of good performance and durability. The product is very easy to maintain

4. The product is appreciated for the features like outstanding performance and long service life. The product is dust-proof and water-resistant

5. Having been tested and modified for several times, the product finally is in its best quality. The product can withstand high-temperature working

Product Description

Structure

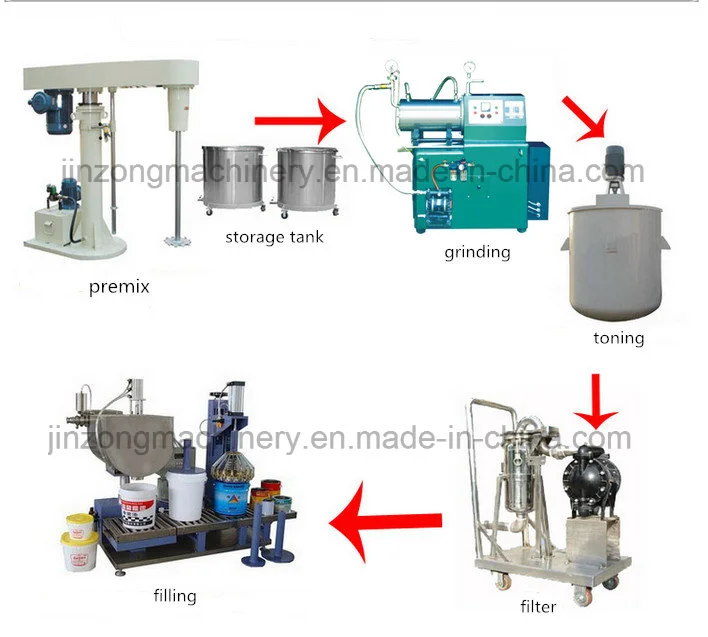

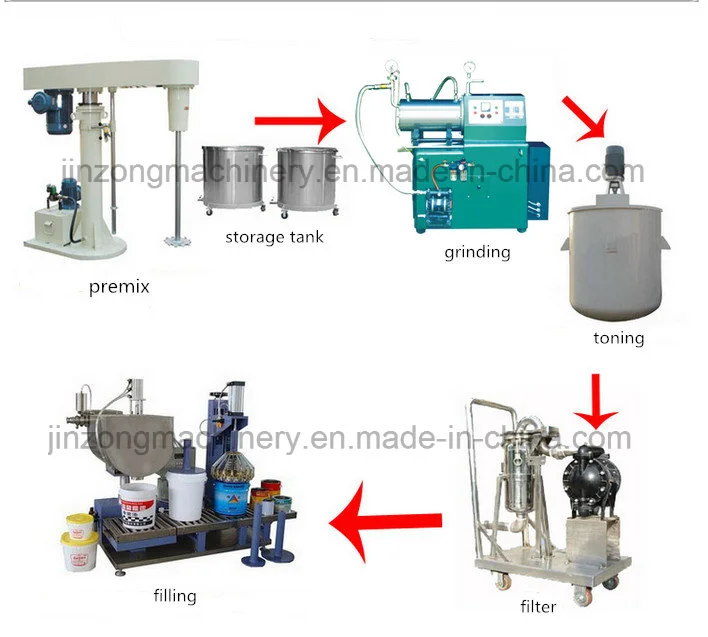

*Independently complete dispersing, griding, vacuum suction, semill-auto filling machine, etc.Slurry mixing and *color mixing executed in one tank.

*Produce water-based paint and slovent-based paint.

*Capacity tank can be 500-5000L.

***Packaging & Shipping

1> Outer packing: plywood case

2> Inner packing: PE film wrapping overall

FOB port: Guangzhou or Shenzhen

***Our Services

Pre-sales service:

1> Engineering design

2> Equipment model selection guide

3> equipment machinig

After-sales service:

1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.

2> Provide professional after-sales service engineers to abroad installation and debugging.

***Company Information

We are a professional manufacturer of cosmetic,chemical& pharmaceutical machinery and equipment more than 17 years .Product lines range from:

Product lines range from:

1> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, color paste mill, filling machine etc.

2> Chemical Machinery: paint/coating production line, high speed disperser, sand mill,three roller mill mixing equipment, separation equipment, storage tank, etc.

3> Biological and Pharmaceutical Machinery: vacuum ointment machine, fermentation tank, sanitary stainless reactor,alcohol deposition can, collocation tank etc.

Our Certificates

***Why Choose Jinzong Machiney?

1. More than 17 years in Cosmetic and cheimical industry

2. Quality, 80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider

3. Good reputation in industry.

4.Have a Professional after-sales service engineering team

5.Large scale and strong strength

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. has created a renowned brand with professionalism.

2. We have a creative design team. With their innovation and motivation, they are able to design innovative products in compliance with the latest modern trends and styles.

3. As a product manufacturer, we always look for materials that could be given a second life, continuously upgrade our packaging methods, and reducing resources wastes to improve sustainability.

1. We work with the best materials sourced from across the globe to give that extra lift to chocolate coating machine 's quality. The product has an alert function for fault detection

2. This product only requires a low number of workers, which helps save labor costs. This will finally help business owners achieve a competitive advantage. The product has the advantage of low energy consumption

3. The product has been tested to be of good performance and durability. The product is very easy to maintain

4. The product is appreciated for the features like outstanding performance and long service life. The product is dust-proof and water-resistant

5. Having been tested and modified for several times, the product finally is in its best quality. The product can withstand high-temperature working

| Model NO. | JZT | Layout Type | Verticle |

| Mixing Drum Shape | Disc | Additional Capabilities | Milling, Drying, Granulating, Coating |

| Operating type | Continuous Operating | Condition | New |

| Brand Name | Jinzong Machinery | Place of Origin | Guangdong, China (Mainland) |

| Voltage | 220V/380V/415V/440V | Warranty | 1 Year |

| After-Sales Service | Engineers Available to Service Machinery Overseas | Trademark | Jinzong Machinery |

| Transport Package | Plywood Case | Specification | CE, ISO, SGS |

| Origin | Guangdong, China(Mainland) | HS Code | 8419899090 |

Product Description

Structure

The production line inculding control system, grinding system, tinting system, discharging and filtration system, filling system.

Main Features*Independently complete dispersing, griding, vacuum suction, semill-auto filling machine, etc.Slurry mixing and *color mixing executed in one tank.

*Produce water-based paint and slovent-based paint.

*Capacity tank can be 500-5000L.

***Packaging & Shipping

1> Outer packing: plywood case

2> Inner packing: PE film wrapping overall

FOB port: Guangzhou or Shenzhen

***Our Services

Pre-sales service:

1> Engineering design

2> Equipment model selection guide

3> equipment machinig

After-sales service:

1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.

2> Provide professional after-sales service engineers to abroad installation and debugging.

***Company Information

We are a professional manufacturer of cosmetic,chemical& pharmaceutical machinery and equipment more than 17 years .Product lines range from:

Product lines range from:

1> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, color paste mill, filling machine etc.

2> Chemical Machinery: paint/coating production line, high speed disperser, sand mill,three roller mill mixing equipment, separation equipment, storage tank, etc.

3> Biological and Pharmaceutical Machinery: vacuum ointment machine, fermentation tank, sanitary stainless reactor,alcohol deposition can, collocation tank etc.

Our Certificates

***Why Choose Jinzong Machiney?

1. More than 17 years in Cosmetic and cheimical industry

2. Quality, 80% materials and components are purchased from 3M, ABB, Siemens, Panasonic, Schneider

3. Good reputation in industry.

4.Have a Professional after-sales service engineering team

5.Large scale and strong strength

Guangdong Jinzong Machinery Co., Ltd.'s products, solutions and services are both competitive and secure. It can effectively prevent the quality deviations of final products with strong processing ability.

Guangdong Jinzong Machinery Co., Ltd. has a complete sales network and perfect after-sales service system. It can effectively prevent the quality deviations of final products with strong processing ability.

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. has created a renowned brand with professionalism.

2. We have a creative design team. With their innovation and motivation, they are able to design innovative products in compliance with the latest modern trends and styles.

3. As a product manufacturer, we always look for materials that could be given a second life, continuously upgrade our packaging methods, and reducing resources wastes to improve sustainability.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. www.jinzongmachinery.com| Sitemap Privacy Policy