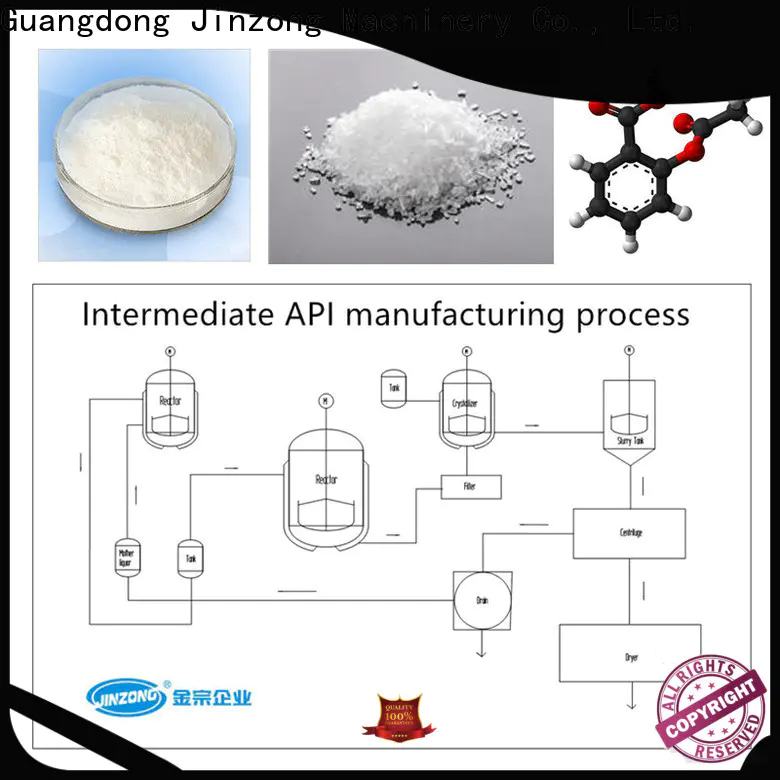

Averbatan intermediate manufacturing plant turnkey solution Glass Lined vessel manufacturerAverbatan intermediate manufacturing process include:

Reaction, quenching, static stratification, extraction, static stratification, combination of organic phase, washing, Scrubbing, concentration, salification, crystallization, centrifugation, drying, milling, packing.

Glass lined vessels is one of the main machinery in this process.Guangdong Jinzong Machinery Co., Ltd. is a professional manufacturer of chemical, biological & pharmaceutical machinery and equipment more than 20 years .

Please do contact us should you have any inquiries about our product. We are competent and are your one stop shopping centre for all your machinery needs.

Please do contact us should you have any inquiries about our product. We are competent and are your one stop shopping centre for all your machinery needs. Jinzong

glass lined reactor structure

The reactor is mainly composed of tank body, insulation material and accessories. The tank body includes inner cylinder, outer cylinder, jacket and supporting foot, etc. Rock wool filling is used as insulation layer between inner cylinder and outer cylinder, jacket form is integrate jacket.

The accessories mainly include sanitary manhole, mirror, light, material and liquid inlet and outlet pipe, thermometer, pressure gauge, etc.

Mechanical stirring: The stirring motor is installed on the top of the tank, and the stirring shaft is composed of the upper half shaft and the lower half shaft, the upper half shaft and the tank body are sealed by filler and have good performance; the lower half shaft is connected with the upper half shaft through flange, and the paddle is welded on the lower stirring shaft, frame type paddle.

Jinzong glass lined reactor specification:

GD series GS series

Application:

Glass line reactor is widely used in Active Pharmaceutical Ingredients API manufacturing process, Intermediate manufacturing process, such as Synthesis reaction, Hydrolysis reaction, quenching reaction, distillation concentration.

Jinzong provides a full range of integrated solutions from R & D Lab test, pilot prodution to large scale production for the API industry, and provides pharmaceutical manufacturer with complete upstream and downstream of API process system design, which can meet the process requirements of different production lines of clients, including fermentation, extraction, chemical synthesis and related supporting systems, and assist customers to achieve high standard and high efficiency process flow.Questions? We can help! Contact us to discuss your project.Project case:

Averbatan intermediate manufacturing plant

Hydrolysis of silkworm chrysalis production line

Extraction of complex amino acids from protein production line

MCC Microcrystalline cellulose manufacturing plant

Diaminobutyric acid manufacturing plant

Vitamin derivatives manufacturing plant