Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery best syrup liquid manufacturing vessel company for pharmaceutical

1. All indicators and processes of Jinzong Machinery syrup liquid manufacturing vessel meet the requirements of national indicators.

2. The product is used in many applications for its quick discharging ability. It is especially useful when there is in need of power source temporarily. The product can realize mobile feeding and output

3. The expected air permeability of this product is determined by the characteristics of the raw material, the geometric characteristics of the yarn used, the structural parameters of the woven fabric, the technology used to produce the fabric and the finishing process. The product can be used in harsh industrial environments

4. The anti-microbial fabrics of this product don’t contain any skin irritants. They’re soft, supple and easy on all types of skin. The product is noted for its high precision

5. An increase in body temperature of only a few degrees can interrupt sleep and can lead to sleepless nights. Yet this product is designed to solve this problem. The product is very easy to maintain

*Mayonnaise Mixing tank with inline homogenizer Machine:

Mayonnaise processing plant is a continuous production plant for manufacturing of mayonnaise and other emulsion foods encompassing advanced technologies.

This is a fully automated system comprising of mixing tanks and buffer tanks that are highly compact. Despite this, the design allows cleaning and maintenance at ease. The complete plant design approach is modernistic and state of art technology promises reduced cost.

Material: SS316L

Design Pressure:-1 -10 Bar (g) or ATM

Work Temperature:0-200 °C

Volumes:5~30000L, customized

If you have any technical requirement,feel free let us know . We can design the tanks according to your requirement .

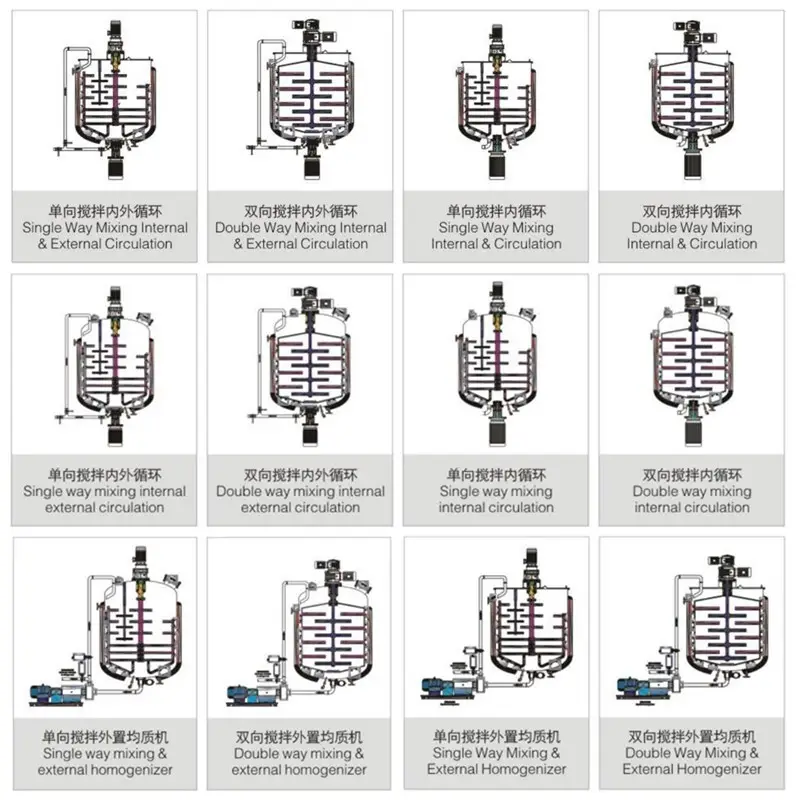

*MAIN COMPOSITION of stainless steel jacket mixing tank:

Stainless steel jacket mixing tank is mainly composed of tank body, mixing system and accessories. The tank body includes inner cylinder, outer cylinder, jacket and supporting foot, etc. Rock wool filling is used as insulation layer between inner cylinder and outer cylinder if needed, jacket form is integrate jacket.

The accessories mainly include sanitary manhole, mirror, light, material and liquid inlet and outlet pipe, thermometer, pressure gauge or customized.

*Stainless steel jacket mixing tank performances and features:

◪ Design compliance with cGMP.

◪ Agitator is on top frame type with scrapper;

◪ Atmospheric, Vacuum or Pressure Operation;

The sugar crystals and water are added to the sugar melting vessel. The steam is supplied and the sugar crystals are melted. Addition of additives manually and it mixes at the set temperature.

The meltdown sugar is transferred to manufacturing vessel after filtration in cone filter through transfer pump. The steam and heat are supplied in manufacturing vessel and the additives are added manually and mixed at the set temperature.

Then the homogenizer performs emulsification and dispersion.

Company Features

1. Professional technology makes sure the quality of syrup liquid manufacturing vessel .

2. Supported by technological innovation, we will always provide customers with high-valued products and win the market share relying on product quality with competitive prices. Please contact.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)