*Description:

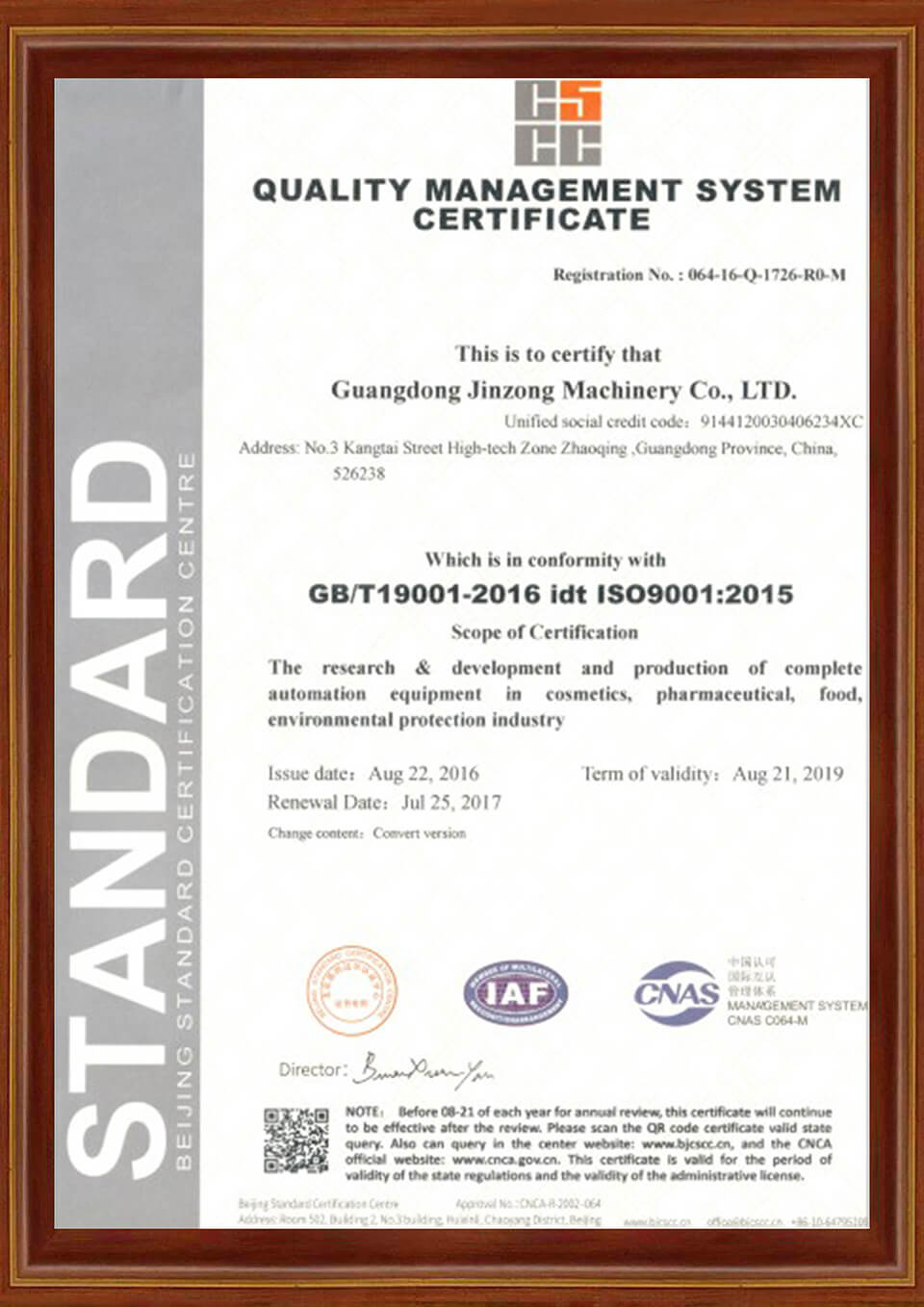

Automatic liquid and cream filling machine is the latest development of our company. Automatic cream filling machine can connect with labeling machine. High-tech enterprise. National patent. Jinzong cream filling machine manufacturers & supplier provides high quality&good service. ISO9001 certification.We have our own cream filling line. The machine can be used for the industry of pharmacy, food, grain and edible oil, grease, oil chemicals, daily chemicals, cosmetics and new materials industries etc.

It can improve production efficiency, reduce the operation intensity, improve the working environment and ensure the filling precision, it is the ideal filling quantitative packaging equipment.

Creams and lotions are some of the most popular cosmetic products used for a variety of skin care treatments. Moreover, some of the creams like acne cream or sunscreen lotion are also used for medical purposes. There is a wide range of creams and lotions available in the market offering various benefits. The cream filling machine is used for filling and sealing processes for filling ointment, lotion, cream, and toothpaste. The creams and lotions vary in thickness based on their usage, which means that different types of cream filling machines can be used for filling and packaging. When it comes to filling, choosing the right cream filler is very important.

*Principle:

Automatic paste liquid filling machine can realize automatically fill. The filling volume, filling velocity, filling precision,filling height, and filling position can be adjusted by the machine.

It is mainly composed of storage tank,the main control cabinet,operation panel,filling the lifting frame parts,pneumatic filling nozzle part,the detection switch& sensor,selector lever,conveying hose, a signal line, power line and other components and accessories. The equipment adopts the modular combination of installation, the main parameters and the set was completed in the operation panel.

The filling process includes: 0 Setting & debugging; ① Take bottles of bottles storage; ②Empty bottles into the conveyor belt;③ Conveying the bottles; ④The back guardrail stopped bottles; ⑤Quantitative filling; ⑥In front guardrail stopped bottles; ⑦The completion of filling,The back guardrail output bottles; ⑧The back guardrail stopped bottles; ⑨In front guardrail output bottles.

When the device is working, require a labor constantly place bottles in front of the equipment, make sure to keep filling.

Note: the equipment in the installation and commissioning, operation, maintenance shall be understood clearly, to avoid the accident loss and accident.

| Filling Volume (ml) | Productivity (b/h) | Filling speed (adjustable) | Filling Precision | Air Supply |

| 10-50 | 1500-3500 | adjustable | ≤±1% | 0.4-0.8MPa |

| 80-300 | 1500-3000 | adjustable | ≤±1% | 0.4-0.8MPa |

| 100-500 | 1500-2500 | adjustable | ≤±1% | 0.4-0.8MPa |

| 300-1000 | 1500-2500 | adjustable | ≤±1% | 0.4-0.8MPa |

| 1000-5000 | 1000-2000 | adjustable | ≤±1% | 0.4-0.8MPa |

◪ Control component and actuator is using the good brand element.All parts contact with product are made of SUS304/SUS316L. Non-metallic parts adopt high standard materials.

◪ Conveyor shell is made of SUS304, durable. Conveyor running smoothly, stepless speed regulation, uniform strong load capacity.

◪ PLC control. The feeding pipe is made of PVC steel pipe.Because the one-way valve is a quickly and accurately cylinder valve, so filling high precision of the equipment, small error.

◪ The automatic cream filling line has automatic transfer bottle, automatic lifting filling nozzle, quantitative filling, uniform filling, emergency stop.

◪ This machine use the cylinder valve filling nozzle.Leakproof plug is arranged in the filling nozzle, prevent the filling nozzle wiredrawing, dropping material.

◪ The machine parts (host, hose, filling nozzle) connected by a fast joint. No special tools required to install.Convenient disassembly, cleaning, maintenance, assembly.

How to choose cream filling machine?

1.ACCURACY AND EFFICIENCY OF CREAM FILLER

Accurate filling of the product is one of the most vital aspects to be considered in product quality. Under filling of the product can lead to customer dissatisfaction and overfilling of the product leads to product wastage. This means the cream filler must be accurate in filling and it should efficiently work for years. Filling accuracy depends on many factors such as product characteristics and machine technology. So, increasing automation can surely help in improving the performance of tube filling machine.

2.USER-FRIENDLY CREAM FILLING MACHINE

Because of technology evolution, automation is increasing day by day. However, user-friendliness is one of the key aspects of any ointment filling machine. It must be easy and user-friendly for the operators to use. Easy operation of the tube filler machine not only improves man-machine interaction, but also improves worker efficiency.

3.CREAM FILLING MACHINE USAGE

The cream filler is highly preferred in cosmetic, pharmaceutical and food industries. When picking a cream filling machine, it is necessary to know the characteristics of the liquid that is going to be filled in bottles or containers. If it is a free-flowing liquid, a timed flow machine is the best option where the same volume of liquid is delivered in each cycle. For products with thicker viscosities, pump fillers and piston fillers are most suitable.

4.PRODUCT AND CONTAINERS

Today, a wide range of creams and lotions is available. As a result, there is a need for fillers that can handle different type of containers. Cream filler manufacturers understand this requirement and they are constantly performing research and development in this direction.

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist