Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

wholesale essential oil extractor jr suppliers for reaction

1. All materials of Jinzong Machinery essential oil extractor meet global standards. The product works under an effective ERP system

2. Guangdong Jinzong Machinery Co., Ltd. can design and produce all kinds of special essential oil extractor according to the requirements of customers. The product can greatly contribute to production efficiency

3. This product is hypoallergenic. All allergens caused by the dyestuff, chemical agents, or other additives are all eliminated during the production. Its frame is designed to reduce heat transmission

4. It is crease resistant. Its weight, weave complexity, composition, and treatment (if any) dictate this fine level of wrinkle resistance. It has a compact design, occupying less space

5. It is well-known for its termite resistance. During the production, it has pre-treated with professional methods such as soaking in the clean water for hours and spraying with an anti-termite agent. The product can be used in harsh industrial environments

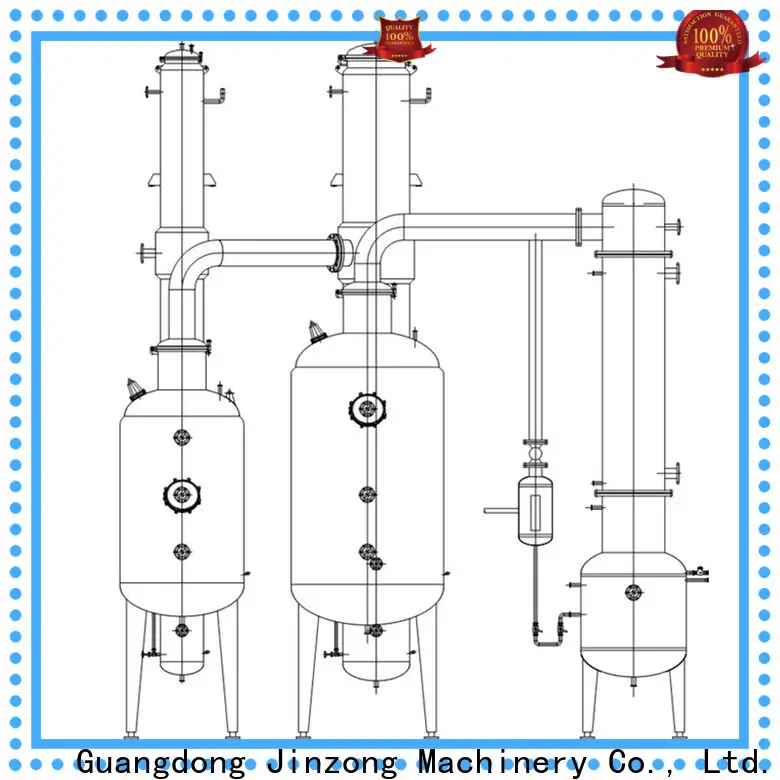

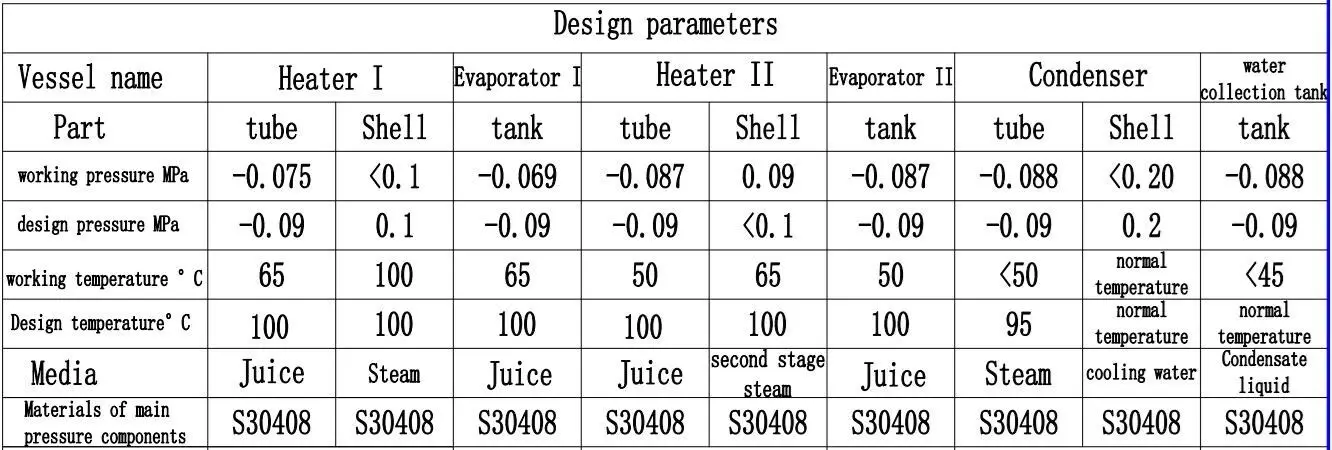

*Low temperature distillation evaporation concentrator juice concentration machine:

Heat-sensitive materials concentration machine Multi-effect Falling Film Evaporator

Low temperature distillation evaporation concentrator juice concentration machine is widely used in pharmaceutical, food, chemical, light industry and other industries, water or organic solvent solution evaporation concentration, and can be widely used in the above industry waste liquid treatment. Especially suitable for heat-sensitive materials, the equipment operates continuously under vacuum and low temperature conditions, with high evaporation capacity, energy saving and consumption reduction, low operating costs, and can ensure the invariance of materials in the evaporation process. The equipment from single-effect to five-effect, production capacity from 1 ton to 10 tons, customers according to material characteristics and production modeling.

1. Evaporation capacity: customized

8. cooling area: customized

9. steam consumption: customized

10. size: customized

Heating chamber, condenser tubes and intermediate connecting pipes are all mirror polished, which ensures smooth flow of materials, no blockage, no coking and clogging phenomenon in heating chamber, reduces scaling and cleaning times, and improves production efficiency.

*If you have any technical requirement,feel free let us know . We can design the tanks according to your requirement .

1. The liquid flow from top to bottom parts by pipe, the liquid can be distributed uniformly, and it flow from top parts to bottom parts by gravity and vacuum, it is heated by steam during running, then it will became into steam and liquid, the steam and liquid will be separated in the chamber, the steam will be cooled by condenser ( single effect ) or used for heating steam, at last the liquid will be discharged from the chamber. it will be sticky during evaporation, and you can get the concentrated liquid at the bottom , the falling film evaporator can evaporate the high density and viscosity(scope from 0.05-0.45ns/m2) material

2. The liquid flows like film in the single type evaporator, so the heat transfer coefficient is high

3. The liquid in the pipe flow very quickly, so it can not be metamorphosis easily, suitable for sensitive product.

4. The retention volume of liquid is small, the falling film evaporator can adopt fast operation, according to changes of energy supplying, vacuum degree, quantity of material feeding, density.

5. Due to fluid flows only under gravity, not pushed by temperature difference, the evaporation can be operated in the low temperature.

6. Falling film evaporator is suitable for foaming material, the liquid can be evaporated in the heating tube like film, forming separation of liquid and vapor. Meanwhile, at the bottom, most liquid will be pumped away, only leaving small part of liquid and the second steam to separating chamber for separation. The liquid doesn’t make the big hit in the process, avoiding the formation of foam

*Heat-sensitive materials concentration machine Multi-effect Falling Film Evaporator:

It is widely used in pharmaceutical, food, chemical, light industry and other industries, water or organic solvent solution evaporation concentration, and can be widely used in the above industry waste liquid treatment. Especially suitable for heat-sensitive materials.

Company Features

1. After years of continuous development, Guangdong Jinzong Machinery Co., Ltd. has become a well-known enterprise in essential oil extractor industry. Guangdong Jinzong Machinery Co., Ltd. never underestimates the importance of quality and technology used in Averbatan intermediate manufacturing plant .

2. Guangdong Jinzong Machinery Co., Ltd. has a production base for the research and development of Intermediate manufacturing plant .

3. It is high technology used in juice concentrator that achieves high quality. As a socially responsible business, we continuously improve and track environmental performance, and improve the understanding and guidance of the environment for all employees.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)