Related Products

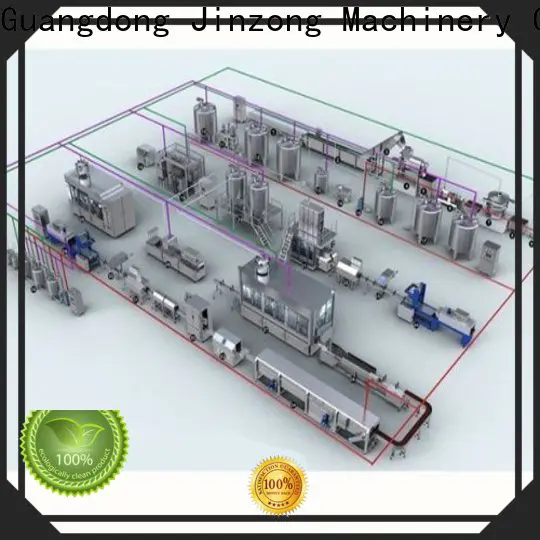

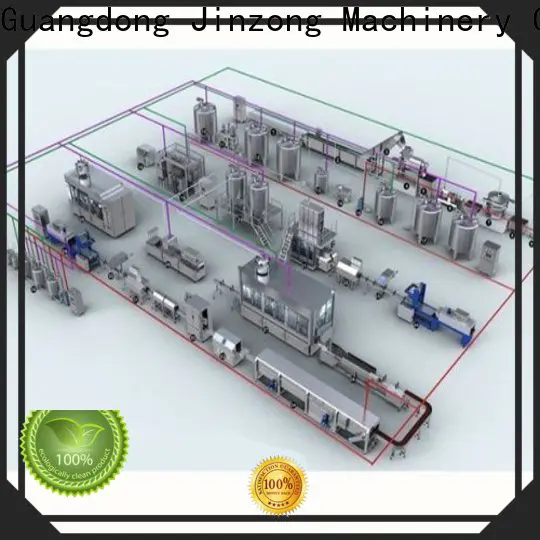

| Trademark | JINZONG | Transport Package | Wooden Case |

| Specification | SUS304, 316L | Origin | Guangdong |

| HS Code | 8419899090 |

Copyright © 2025 Guangdong Jinzong Machinery Co., Ltd. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist