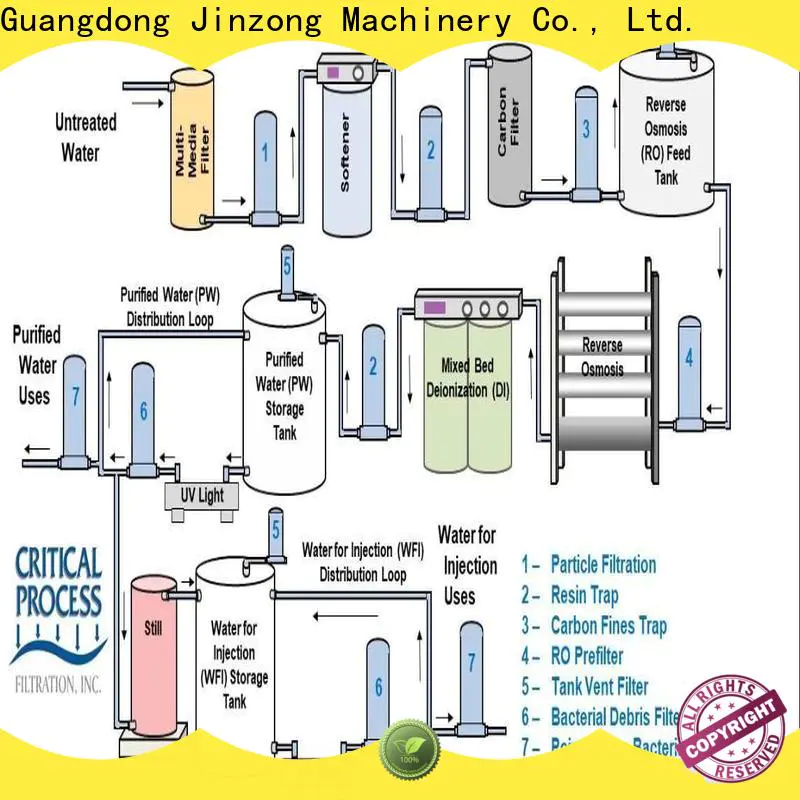

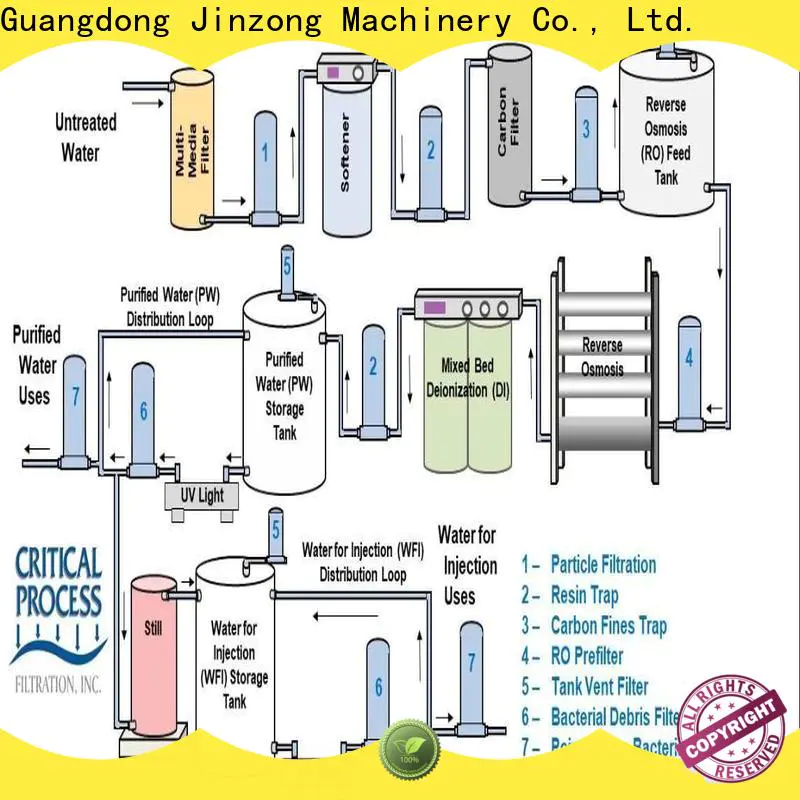

Purified Water for Injection (WFI) System RO pure Water Filters System

The water used in the pharmaceutical industry, used both in drug synthesis, cleaning, as well as Water for Injection needs to meet strict quality requirements according to various Pharmacopeia. Water Treatment Systems and process equipment for the pharmaceutical industry need to be sanitizeable by steam and for this reason materials are used that can withstand high temperatures. Highly polished materials (mostly SS) need to be used to prevent the growth of biofilm. Sanitary pumps are used that minimize particle shedding and no ball valves are allowed because they can harbor biofilm.

Prefiltration

Incoming water from a municipal source or a well contains particles and sediment that can interfere with treatment components. The filters protect systems from both inorganic and organic debris in source water, trap particles generated by multi-media filters, carbon beds or softeners, and capture particles to protect RO membranes

The eight types of water used in the pharmaceutical industry are:

1. Non-potable for cooling

2. Potable (drinkable) water

3. USP purified water

4. USP water for injection (WFI) - Distillation must be used for this type of water according to European Pharmacopeia

5. USP sterile water for injection

6. USP sterile water for inhalation

7. USP bacteriostatic water for injection (contains an anti-bacterial agent)

8. USP sterile water for irrigation - irrigation in medicine means the washing of a body cavity or wound by a stream of water

Pure water for various pharma applcations needs to be demineralized, the organics and SS in it removed and the water disinfected/sterilized to make sure there are no bacteria. Technologies such sa Micro-Filtration, UF, RO, IEX, EDI, Distillation and UV are used. Stored water is nornally circulated at a high temperature to prevent biofilm growth. Systems are designed to prevent dead legs and allow easy drainage for cleaning. The facilities housing the water treatment equipment must be controlled and prevent cross contamination from outside.

Don't go it alone. Our technical experts can help you target a solution from the many choices and variables.

When filtration performance isn't meeting expectations, or you're developing a new process and a fresh perspective is needed, you can count on us to help troubleshoot and configure the best-fit solution for your operation.