Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery vacuum Vitamin derivatives manufacturing plant for business for pharmaceutical

1. The design of Jinzong Machinery is the result of professional knowledge. It takes into account the principles of biomechanics, the principle of physical structural mechanics and ergonomics, and the Weight Distribution System (WDS). The product has passed the CE certification

2. For most workers, this product is a safe choice. It can reduce human error and risk phenomena caused by common faults. It can effectively prevent the quality deviations of final products with strong processing ability

3. This product is warranted to be free from defects in quality and performance with normal manufacturing tolerances and quality control procedures. The product has high sensitivity to quickly respond to users' operation

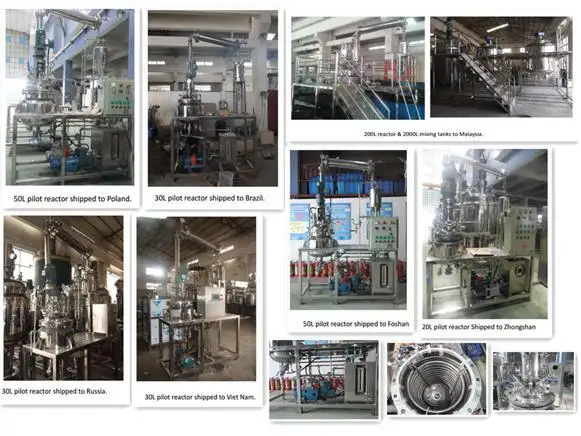

Pilot reactor:

Material:SS304, 304L, 316 or SS316L

Design Pressure:-1 -10 Bar (g) or ATM

Work Temperature:0-200 °C or customized

Volumes:5~200L, customized

We can provide users with engineering design, equipment model selection guide, equipment machinig, equipment installation and turn-key project from pilot plant to large scale manufacturing plant.

*MAIN COMPOSITION of pilot reactor:

Pilot is mainly composed of Reaction vessel, mixing system, vacuum system, condenser, receiver/storage tank, conduction oil preheating system, platform, etc.

Heating and cooling method: 1. Heating and cooling by jacket. 2. Heating by jacket and cooling by inner pipe coil.

Type of electrical device: 1. Ex-proof type. 2. Normal type

Electric cabinet control mode: 1. Touch-screen control. 2. Button control

*pilot reactor small scale reaction plant performances and features:

◪ Design compliance with cGMP.

◪ , Long operational life, Less maintenance

◪ Excellent functionality;

*pilot reactor:

It is widely used for reaction, evaporation, concentration, synthesization, polymerization, mineratization, etc. in pharmaceutical industry, chemical industry, dye, pesticide, organic synthesis, petroleum, food additives, industry of national defense and scientific research.

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. has been considered as one of the most powerful and competitive manufacturers of [核心关键词. We have gained years of experience. Guangdong Jinzong Machinery Co., Ltd. has patented advanced technology in the development of Vitamin derivatives manufacturing plant .

2. Guangdong Jinzong Machinery Co., Ltd. has powerful technical advantage and can develop syrup manufacturing plant .

3. Compared with other companies, Guangdong Jinzong Machinery Co., Ltd. has a higher and more advanced technical level. While pursuing the growth of the company, Guangdong Jinzong Machinery Co., Ltd. always adhere to . Inquire!

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)