Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery top ointment filling machine online for pharmaceutical

1. Jinzong Machinery is designed with high standard. It is designed to meet, tested or compliant with such international standards as IP Protection, UL, and CE. The product has an alert function for fault detection

2. Jinzong Machinery is a professional ointment filling machine maker which enjoys a better reputation among the customers. The product has the merit of full traceability

3. The product features an effective and thorough cleaning effect. It is created to fit flexibility to curved corners and the hard to reach places. It is resistant to breakage with its sturdy frame

4. It resists the growth of mold and mildew. It is coated with mold prevention paint which is very effective in removing mold and keeping it from returning. The product has the advantage of low energy consumption

5. The product has good temperature adaptability. It can work under a wide range of temperature and it has been optimized with high-temperature performance. The product is dust-proof and water-resistant

*Mayonnaise Mixing tank with inline homogenizer Machine:

Mayonnaise processing plant is a continuous production plant for manufacturing of mayonnaise and other emulsion foods encompassing advanced technologies.

This is a fully automated system comprising of mixing tanks and buffer tanks that are highly compact. Despite this, the design allows cleaning and maintenance at ease. The complete plant design approach is modernistic and state of art technology promises reduced cost.

Material: SS316L

Design Pressure:-1 -10 Bar (g) or ATM

Work Temperature:0-200 °C

Volumes:5~30000L, customized

If you have any technical requirement,feel free let us know . We can design the tanks according to your requirement .

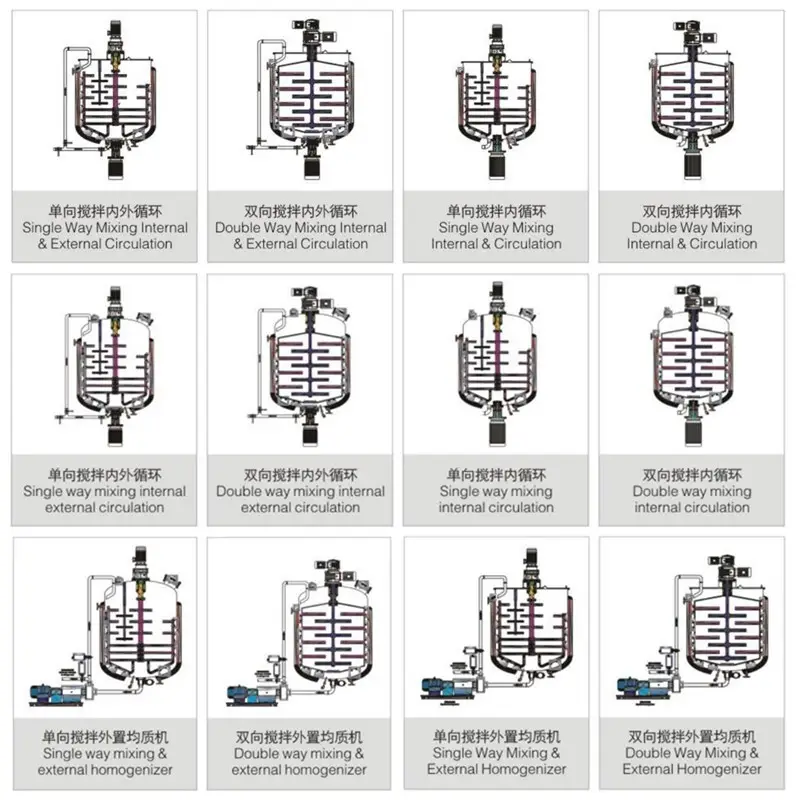

*MAIN COMPOSITION of stainless steel jacket mixing tank:

Stainless steel jacket mixing tank is mainly composed of tank body, mixing system and accessories. The tank body includes inner cylinder, outer cylinder, jacket and supporting foot, etc. Rock wool filling is used as insulation layer between inner cylinder and outer cylinder if needed, jacket form is integrate jacket.

The accessories mainly include sanitary manhole, mirror, light, material and liquid inlet and outlet pipe, thermometer, pressure gauge or customized.

*Stainless steel jacket mixing tank performances and features:

◪ Design compliance with cGMP.

◪ Agitator is on top frame type with scrapper;

◪ Atmospheric, Vacuum or Pressure Operation;

The sugar crystals and water are added to the sugar melting vessel. The steam is supplied and the sugar crystals are melted. Addition of additives manually and it mixes at the set temperature.

The meltdown sugar is transferred to manufacturing vessel after filtration in cone filter through transfer pump. The steam and heat are supplied in manufacturing vessel and the additives are added manually and mixed at the set temperature.

Then the homogenizer performs emulsification and dispersion.

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. is one of the prominent manufacturers of . Over the years, we have been focusing on design and production.

2. Different mechanisms are provided for fabricating different ointment filling machine .

3. By striving with all the might, Jinzong Machinery has enough confidence to achieve the goal of being a world famous brand. Get info!

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)