Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

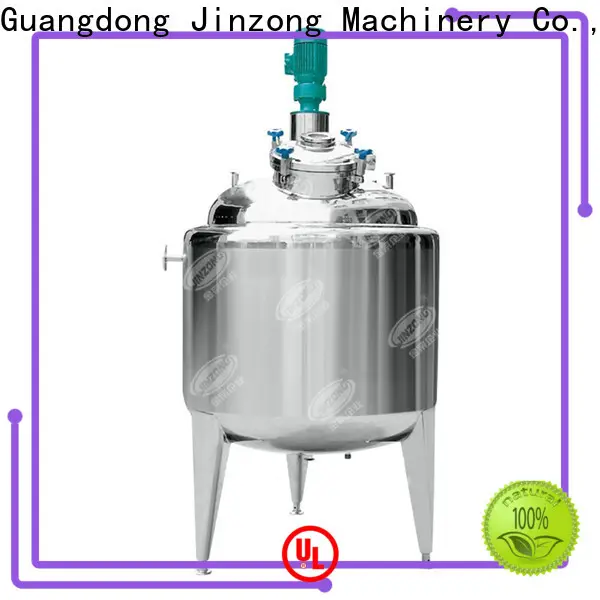

Jinzong Machinery series emulsifying mixing tank factory for reflux

*DEFINITION OF Stainless steel jacket mixing tank:

It has the heating, cooling ,mixing functions. It is an indispensable equipment for dairy, beverage and pharmaceutical manufacturers.

Material:SS304, 304L, 316 or SS316L

Design Pressure:-1 -10 Bar (g) or ATM

Work Temperature:0-200 °C

Volumes:5~30000L, customized

We can supply double-layer and three-layer stainless steel jacket mixing tanks.

We also supply electrical heating, heat conductive oil heating jacket mixing tanks.

If you have any technical requirement,feel free let us know . We can design the tanks according to your requirement .

*MAIN COMPOSITION of stainless steel jacket mixing tank:

Stainless steel jacket mixing tank is mainly composed of tank body, mixing system and accessories. The tank body includes inner cylinder, outer cylinder, jacket and supporting foot, etc. Rock wool filling is used as insulation layer between inner cylinder and outer cylinder if needed, jacket form is integrate jacket.

The accessories mainly include sanitary manhole, mirror, light, material and liquid inlet and outlet pipe, thermometer, pressure gauge or customized.

*Stainless steel jacket mixing tank performances and features:

◪ Design compliance with cGMP.

◪ Agitator can be top or bottom driven or magnetically driven;

◪ Atmospheric, Vacuum or Pressure Operation;

*Stainless steel jacket mixing tank:

Jinzong machinery stainless steel jacket mixing tank is widely used in physical mixing, reaction, evaporation, concertration, crystallization, fermentation, dispersion composition, extraction, saponification, mineralization, chlorination, nitration etc. Of chemical, pharmaceutical, dye, pesticide, organic synthesis, petroleum, food additives, defense industry and scientific research.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)