Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery rollers dry powder mixer factory for industary

1. Jinzong Machinery is designed perfectly and made with best materials. The product is highly automatic and controllable

2. With the above good characteristics, the product has good competition capacity and a good development prospect. The product has an alert function for fault detection

3. The product features high abrasion resistance. It is able to keep itself from without becoming deformed or indented by hard physical objects. Its frame is designed to reduce heat transmission

*Description:

Three rollers mill is mainly used for paint, ink, plastic, paint, food and other paste materials, especially suitable for grinding high viscosity and particle size of fine products. Roll is made of chilled alloy cast iron centrifugal casting, so the crystal phase is closely , high strength, the surface has high hardness and wear resistance, and is provided with a cooling system.

The machine by rotating the handwheel adjustment of the horizontal direction of the three rollers between the gap and the roller surface of jiga and different speed friction to grind dispersing effect.

Packaging & Shipping: Outer packing: plywood case; Inner packing: PE film wrapping overall; FOB port: Guangzhou or Shenzhen

| Model | S65 | S150 | S260 | S405 | SM405 | |

| Roller dia.(mm) | 65 | 150 | 260 | 405 | 405 | |

| Working length(mm) | 125 | 300 | 675 | 810 | 810 | |

| Speed | Slow(r/min) | 26 | 26 | 19.1 | 12.2 | 14.25 |

| Middle(r/min) | 70 | 70 | 54.5 | 37.6 | 44 | |

| Fast(r/min) | 145 | 145 | 155.3 | 116 | 135.5 | |

| Motor(kw) | 0.55 | 2.2 | 7.5 | 15 | 15 | |

| Size(mm) | 410×550×450 | 1010×930×1000 | 1645×1350×1100 | 2100×1950×1350 | 2290×1950×1350 | |

| Weight(kg) | 85 | 550 | 2200 | 5000 | 5200 | |

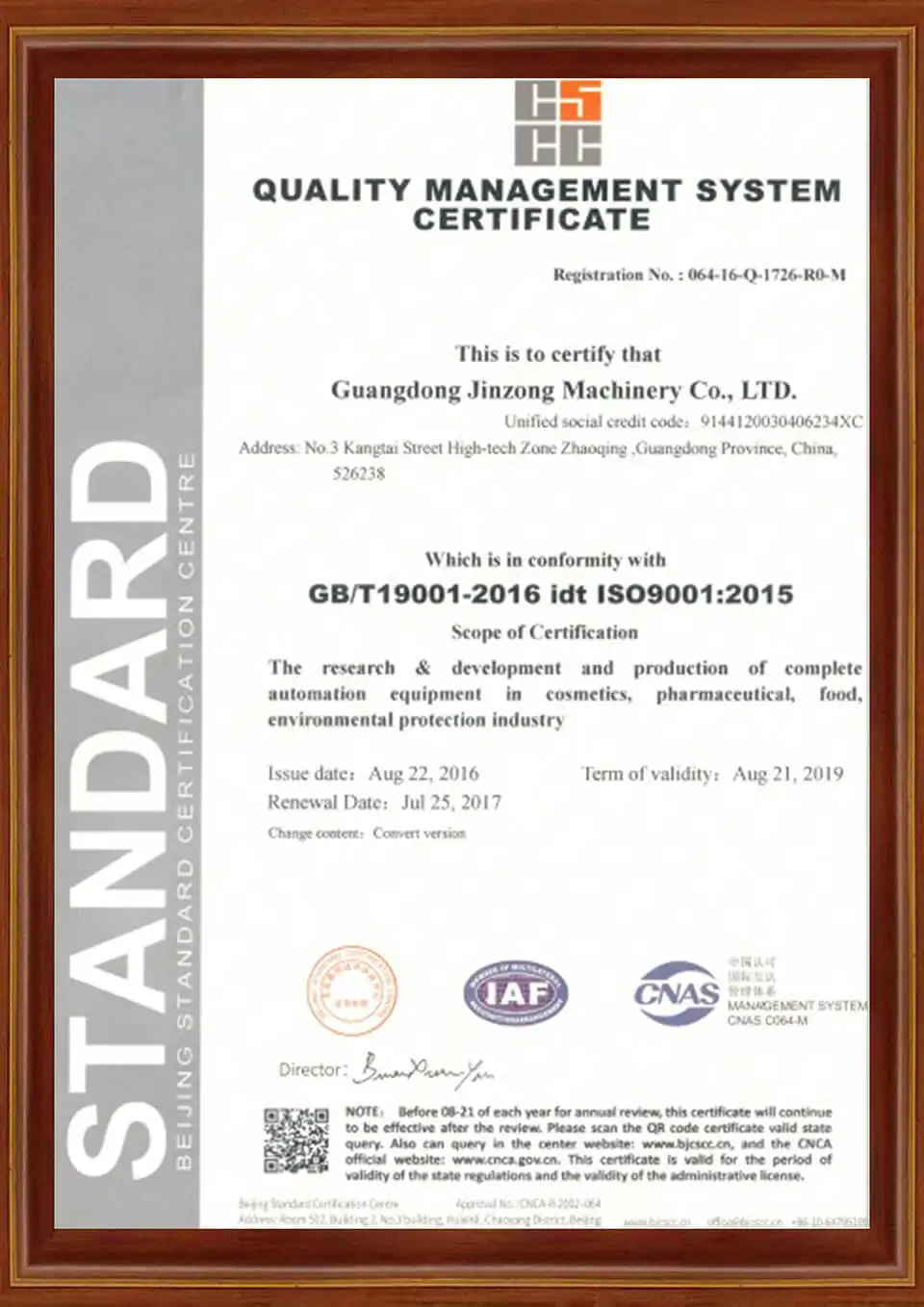

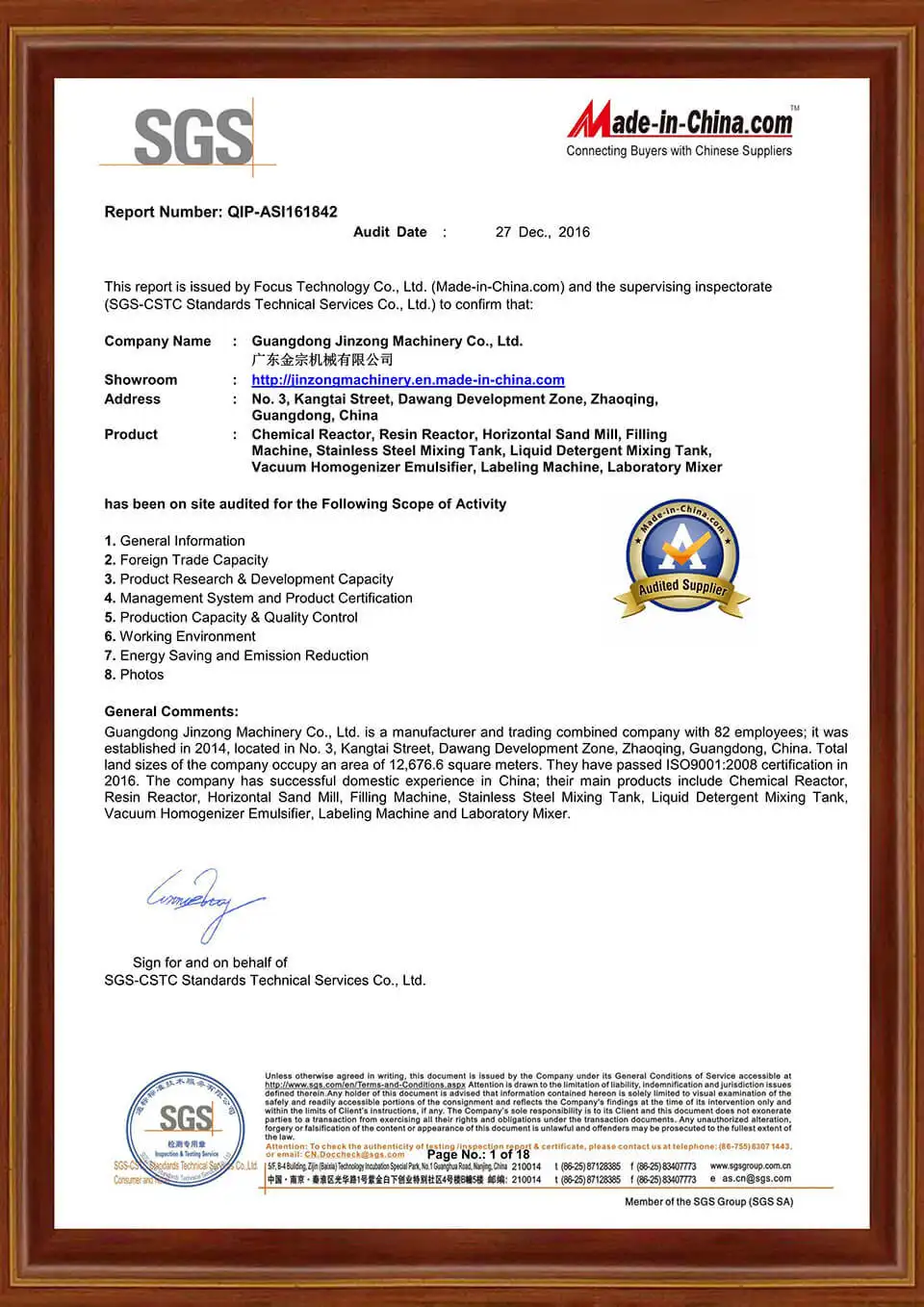

Company Features

1. The introducing of advanced machine ensures the quality of our dry powder mixer.

2. Jinzong Machinery will constantly creating profits for its customers. Please contact.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)