Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery powder dry powder mixer factory for plant

1. Jinzong Machinery dry powder mixer has passed many tests conducted by independent testing institutes. It has been tested with regards to flexibility, stability, slip and abrasion resistance. The product is extremely resistant to corrosion

2. This product is widely used in various applications and has great market potential. The product is very easy to maintain

3. This product is safe. It uses zero-VOC or low-VOC materials and has been tested specifically concerning oral toxicity, skin irritation, and respiratory effects. The product has high sensitivity to quickly respond to users' operation

*Description:

Jinozng Horizontal Nanomills system combines the well-known special separation system designed by Jinzong. This agitator bead mill was specifically developed by Jinzong engineers for high energy, high flow, multiple pass and specifically circulation operation grinding to achieve very narrow submicron particle size distributions with excellent repeatability.

Mainly designed for the middle and small lot manufacture of middle and high class product.

Using solvent discharging valve gear in the small mill barrel can make no material draffy remain in the barrel consequently reduce the waste.

This machine is very economic for middle and small manufacture and can meet more requirement of customer.

The high precision separation device can use those mill beads which has small diameter and get high output.

| Type | IN-6 | IN-10 | IN-30 | IN-60 |

| Tank capacity(L) | 6 | 10 | 30 | 60 |

| Motor power(KW) | 15 | 22 | 45 | 75 |

| Production capacity(KG/h) | 40-200 | 100-500 | 500-2500 | 1000-6000 |

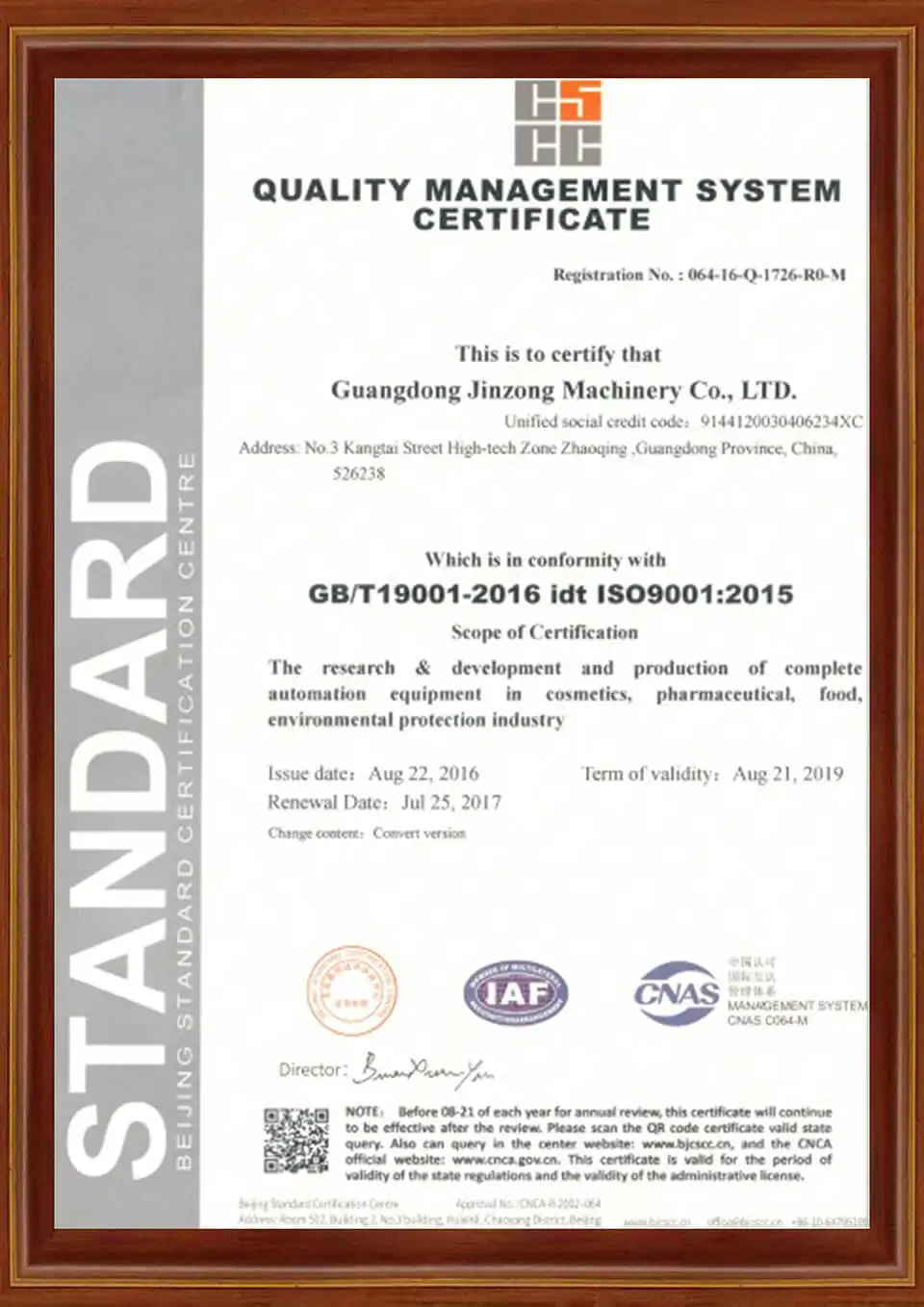

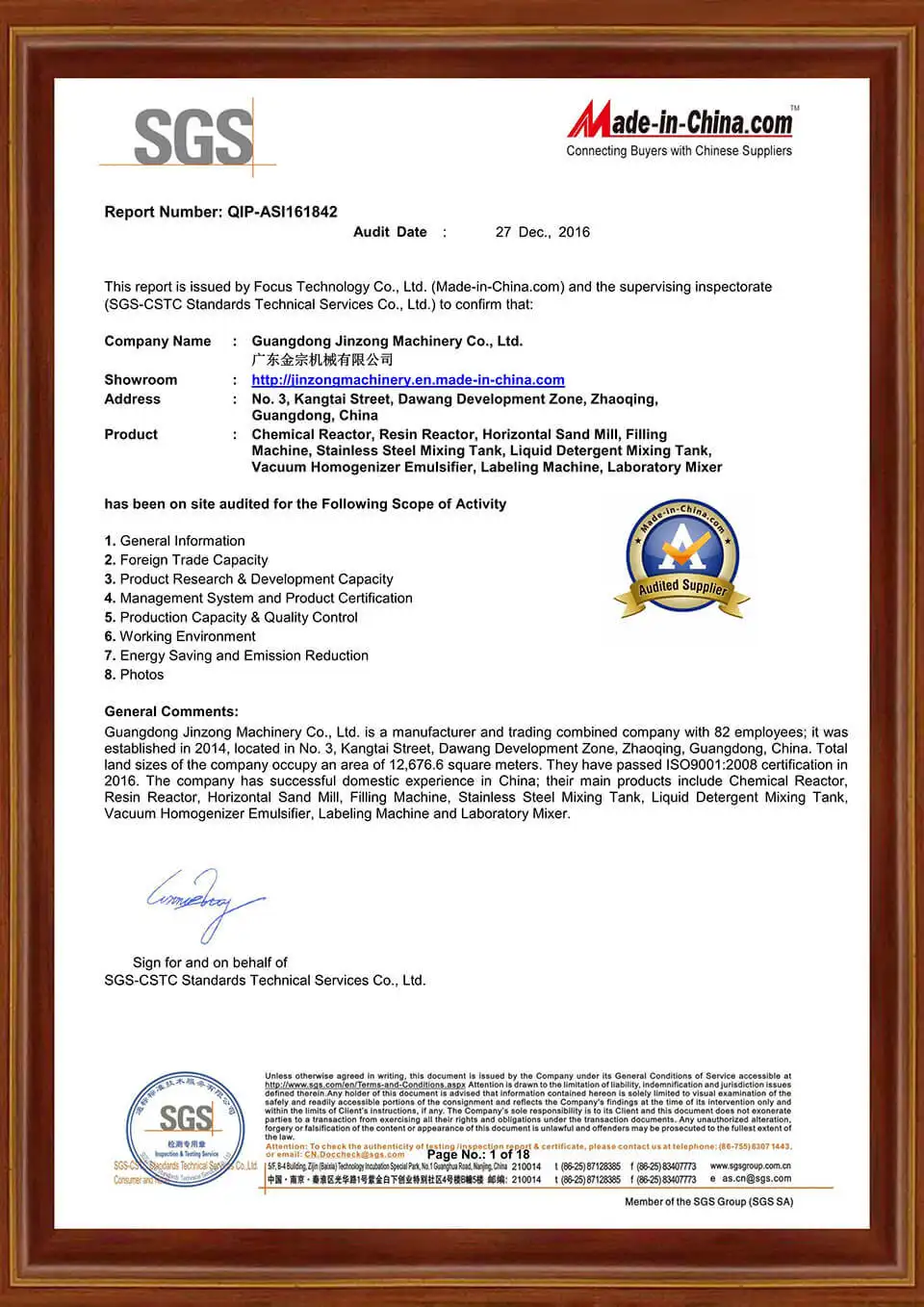

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. has been an expert in the design, manufacture, and sales of dry powder mixer. We are regarded as one of the most powerful manufacturers in China. To be able to develop into a capable firm, Jinzong Machinery has consistently introduced high-end technologies.

2. Guangdong Jinzong Machinery Co., Ltd. is great at learning and upgrading horizontal milling machine technology.

3. Jinzong Machinery has a design center, a standard R&D department, and a engineering department. Guangdong Jinzong Machinery Co., Ltd. always puts customers at first place and will actively help customers solve problems. Inquire now!

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)