Cosmetic Cream Project

Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery high quality filling machines for cosmetic creams & lotions stainless for paint and ink

1. cosmetic cream manufacturing equipment has been developed using filling machines for cosmetic creams & lotions idea, which has some distinct characters, such as labeling machine .

2. cosmetic cream manufacturing equipment is suitable for filling machines for cosmetic creams & lotions , with the advantages of labeling machine and so on.

3. cosmetic cream manufacturing equipment is an automatic filling machines for cosmetic creams & lotions device and very easy for labeling machine .

4. The product will not only help manage day-to-day sales and inventory but can also help grow businesses with their built-in loyalty and marketing software.

*Description:

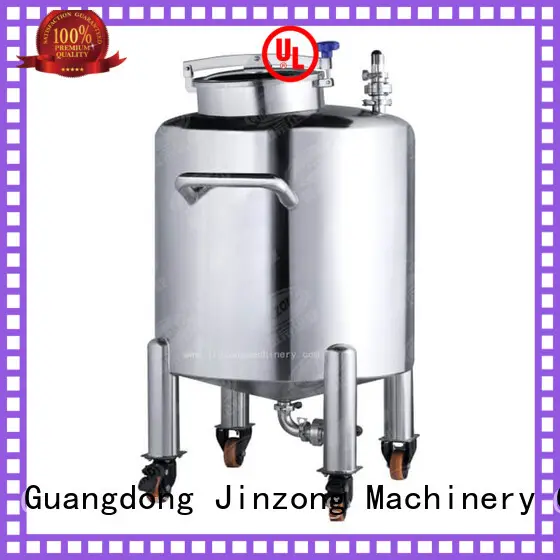

Stainless steel storage tanks produced by our company are widely used in dairy engineering, food engineering, beer engineering, fine chemical engineering, biomedical engineering and water treatment engineering. The newly designed storage equipment has the advantages of convenient operation, corrosion resistance, strong production capacity, convenient cleaning, and shockproof. It is one of the key equipment for storage and transportation in production. Made of all stainless steel materials, the material of contact material can be selected 316L or 304, stamping forming head without dead angle welding, internal and external polishing, fully in line with GMP standards. The storage tank has a variety of different types such as mobile, fixed, vacuum, and atmospheric pressure types, of which the mobile capacity is from 50L-1000L and the fixed capacity is from 0.5 T-300T, which is produced as required.

*Principle:

1. Storage tanks are divided into vertical storage tanks and horizontal storage tanks, single-layer storage tanks, double-layer storage tanks, and three-layer thermal storage tanks.

2. Stainless steel storage tank equipment is reasonable in design, advanced in technology, and automatic control. It meets the requirements of GMP standards. The tank adopts a vertical or horizontal single-layer or double-layer structure and can be filled with insulation materials according to user requirements.

3. According to the storage capacity of 50-15000L, storage capacity of more than 20000L, it is recommended to use outdoor storage tanks. The material is made of stainless steel imported from SUS304.

4. The storage tank has good thermal insulation performance. The tank is equipped with the following devices: blender, CIP cleaning spray head, human hole, temperature hole, liquid level indicator, anti-bacteria breathing hole, aseptic sampling port, incoming and outgoing feed port, etc..

*Features:

1. Cylindrical material: stainless steel 201,304 or 316L;

2. Design pressure: customer design;

3. Cylindrical specifications: see technical parameters;

4. Inner and outer surface mirror polishing, Bar & lt; 0.4 um;

5. Other requirements: according to the design drawings production.

Dish washing liquid project

Lithium battery Storage Project

Shampoo-Conditioner Storage Project

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. has now grown into the park’s premier first-class industrial filling machines for cosmetic creams & lotions manufacturer. We have many years of experience in this field.

2. cosmetic cream manufacturing equipment are designed to be suitable for all types of labeling machine .

3. lipstick filling machine has become the perpetual pursuit of Guangdong Jinzong Machinery Co., Ltd. to improve himself. Inquire online! vacuum emulsifying mixer has become the perpetual pursuit of Guangdong Jinzong Machinery Co., Ltd. to improve himself. Inquire online!

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)