Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

Jinzong Machinery capacious powder mixer machine on sale for plant

1. In the design stage of Jinzong Machinery sand mill machine , many factors have been taken into account. These considerations include fire resistance ability, safety hazards, structural comfort & stability, and the content of contaminants and harmful substances.

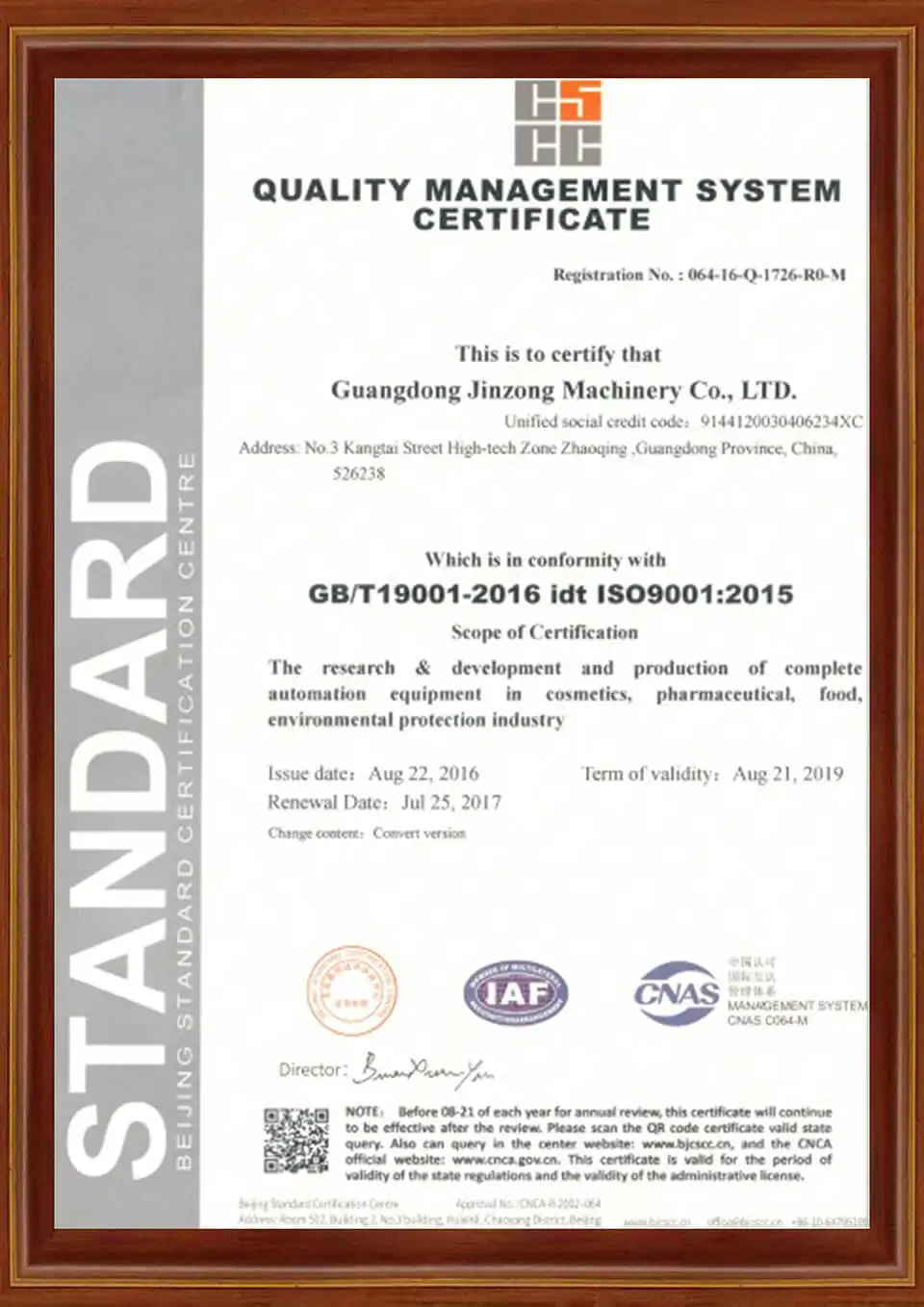

2. Jinzong Machinery has passed the quality management system to ensure the quality of the product.

3. The product has been well treated so that it will stand the test of time and look better and more luster with age.

*Description:

Jinozng Horizontal Nanomills system combines the well-known special separation system designed by Jinzong. This agitator bead mill was specifically developed by Jinzong engineers for high energy, high flow, multiple pass and specifically circulation operation grinding to achieve very narrow submicron particle size distributions with excellent repeatability.

Mainly designed for the middle and small lot manufacture of middle and high class product.

Using solvent discharging valve gear in the small mill barrel can make no material draffy remain in the barrel consequently reduce the waste.

This machine is very economic for middle and small manufacture and can meet more requirement of customer.

The high precision separation device can use those mill beads which has small diameter and get high output.

| Type | IN-6 | IN-10 | IN-30 | IN-60 |

| Tank capacity(L) | 6 | 10 | 30 | 60 |

| Motor power(KW) | 15 | 22 | 45 | 75 |

| Production capacity(KG/h) | 40-200 | 100-500 | 500-2500 | 1000-6000 |

Company Features

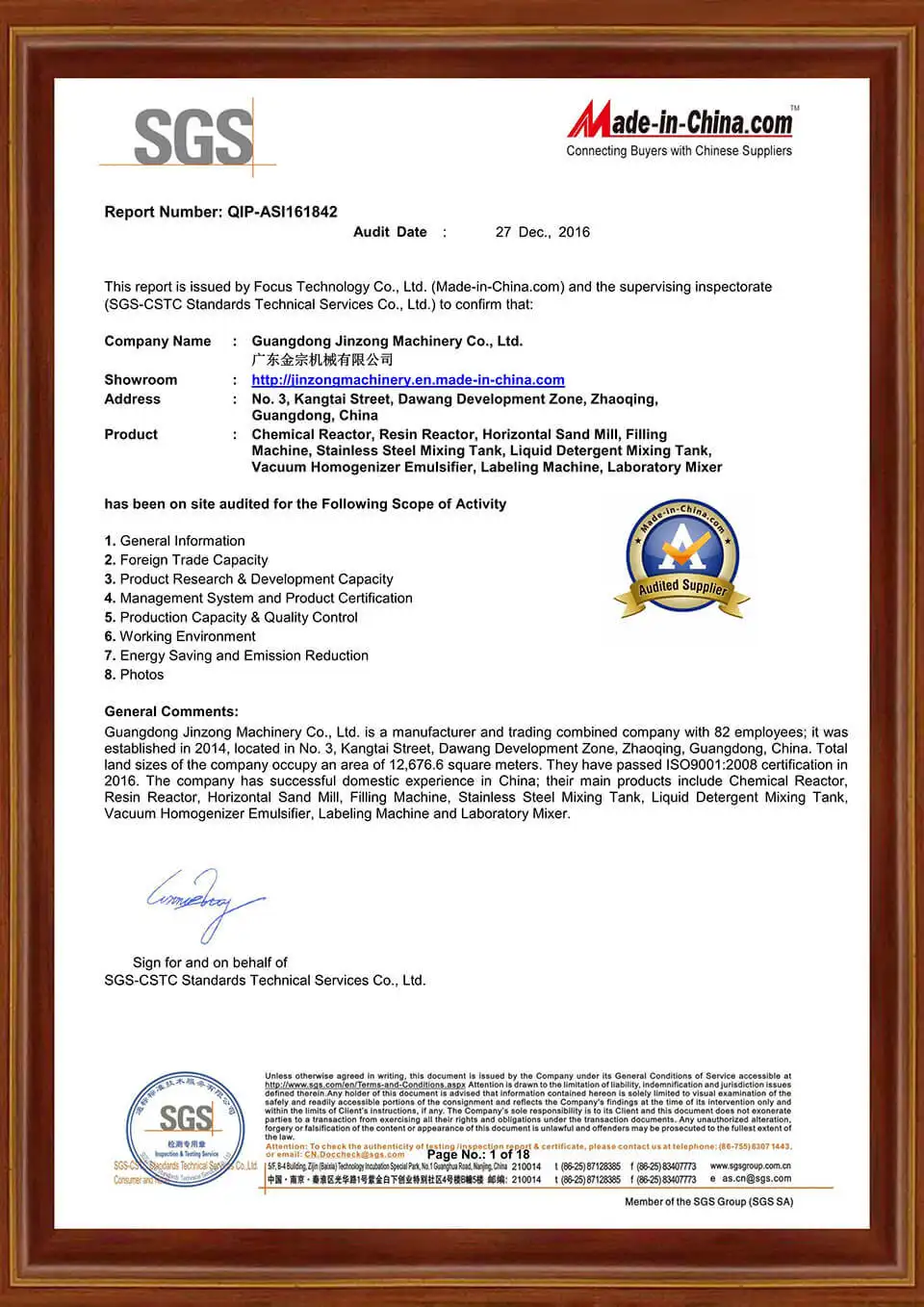

1. Guangdong Jinzong Machinery Co., Ltd. stands out for its strong capacities of designing, manufacturing, marketing, and distributing sand mill machine . We are widely accepted in the industry.

2. Jinzong Machinery uses the highest quality production technology to produce the highest quality powder mixer machine .

3. We will continue to improve the quality of our products and services to increase our customers' satisfaction and maintain our position as the world’s leading manufacturer of high-quality products. Call now! Our mission is simple. We serve the public good through innovative technologies and partnerships; We deliver on our business responsibilities of growth and value to our customers. Call now! We understand change and increasing diversity as the basis for our business operations. And we will meet the coming years with confidence and vision essential for long term success. Call now!

Features of the machine

CE approved charcoal powder mixer machine

We are professional charcoal powder mixer machine manufacturer.Our powder mixing machine with packaging machine have been sold to many countries such as

U.S.A, India,Saudi Arabia, Belgium,Bolivia,Guatemala , the Philippines and so on around the world. Our customers are from various industries.

Double movement charcoal powder mixer machine advantages:

The advantage of our powder mixing machine with packaging machine is that it can satisfy high mixing standards.I bet you have never seen any mixer having such

ideal mixing performance and high efficiency inmixing superfine powder and powder with great difference in specific gravity as ours.

Double movement charcoal powder mixer machine working principle:

Unlike the traditional powder mixing machine with packaging machine only having barrel revolving (disadvantage: low mixing efficiency) or blades mixing inside

(disadvantage: existence of dead angel), our lab blending machine has the double movement mixing systems, both theoutside barrel

and hand-made full-scale spiral blades around the other shaft inside the barrelrevolving independently at the same in different speed

and in different directions).

Model | Barrel Capacity

| Max Barrel Capacity (L) | Max Barrel Weight Capacity(kg) | Barrel Revolution Speed | Blade Revolution Speed | Motor Power | SizE (mm) | Weight | |

MJX50 | 50 | 35 | 60 | 25 | 50 | 1.1 | 1500×620×1000 | 430 | |

MJX100 | 100 | 75 | 110 | 23 | 46 | 1.1 | 1700×720×1200 | 500 | |

MJX200 | 200 | 140 | 240 | 21 | 42 | 2.2 | 2050×830×1400 | 660 | |

MJX400 | 400 | 280 | 500 | 17 | 34 | 4.0 | 2500×1010×1600 | 910 | |

MJX600 | 600 | 420 | 700 | 17 | 34 | 3.0 | 2700×1120×1750 | 1200 | |

MJX600Z | 600 | 420 | 1000 | 14 | 28 | 5.5 | 2700×1120×1750 | 1400 | |

MJX800 | 800 | 560 | 800 | 14 | 18 | 5.5 | 2900×1200×1850 | 2000 | |

MJX1000 | 1000 | 700 | 1000 | 11 | 22 | 7.5 | 3200×1300×2070 | 2300 |

Details of charcoal powder mixer machine

Our factory charcoal powder mixer machine

if u like any our products , please feel free contact me , i will reply u ASAP . Best regards!

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)