Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

horizontal sand mill manufacturers iron for plant Jinzong Machinery

1. The raw materials of Jinzong Machinery sand mill manufacturers are paid 100% attention during selecting. The defective raw materials are all eliminated before entering the factory and thus they are of high performance.

2. Compared with the other similar products, powder mixer machine has a lot of advantages, such as sand mill manufacturers .

3. People with sensitive skin or conditions such as eczema or psoriasis will feel comfortable wearing this skincare product.

*Description:

Three rollers mill is mainly used for paint, ink, plastic, paint, food and other paste materials, especially suitable for grinding high viscosity and particle size of fine products. Roll is made of chilled alloy cast iron centrifugal casting, so the crystal phase is closely , high strength, the surface has high hardness and wear resistance, and is provided with a cooling system.

The machine by rotating the handwheel adjustment of the horizontal direction of the three rollers between the gap and the roller surface of jiga and different speed friction to grind dispersing effect.

Packaging & Shipping: Outer packing: plywood case; Inner packing: PE film wrapping overall; FOB port: Guangzhou or Shenzhen

| Model | S65 | S150 | S260 | S405 | SM405 | |

| Roller dia.(mm) | 65 | 150 | 260 | 405 | 405 | |

| Working length(mm) | 125 | 300 | 675 | 810 | 810 | |

| Speed | Slow(r/min) | 26 | 26 | 19.1 | 12.2 | 14.25 |

| Middle(r/min) | 70 | 70 | 54.5 | 37.6 | 44 | |

| Fast(r/min) | 145 | 145 | 155.3 | 116 | 135.5 | |

| Motor(kw) | 0.55 | 2.2 | 7.5 | 15 | 15 | |

| Size(mm) | 410×550×450 | 1010×930×1000 | 1645×1350×1100 | 2100×1950×1350 | 2290×1950×1350 | |

| Weight(kg) | 85 | 550 | 2200 | 5000 | 5200 | |

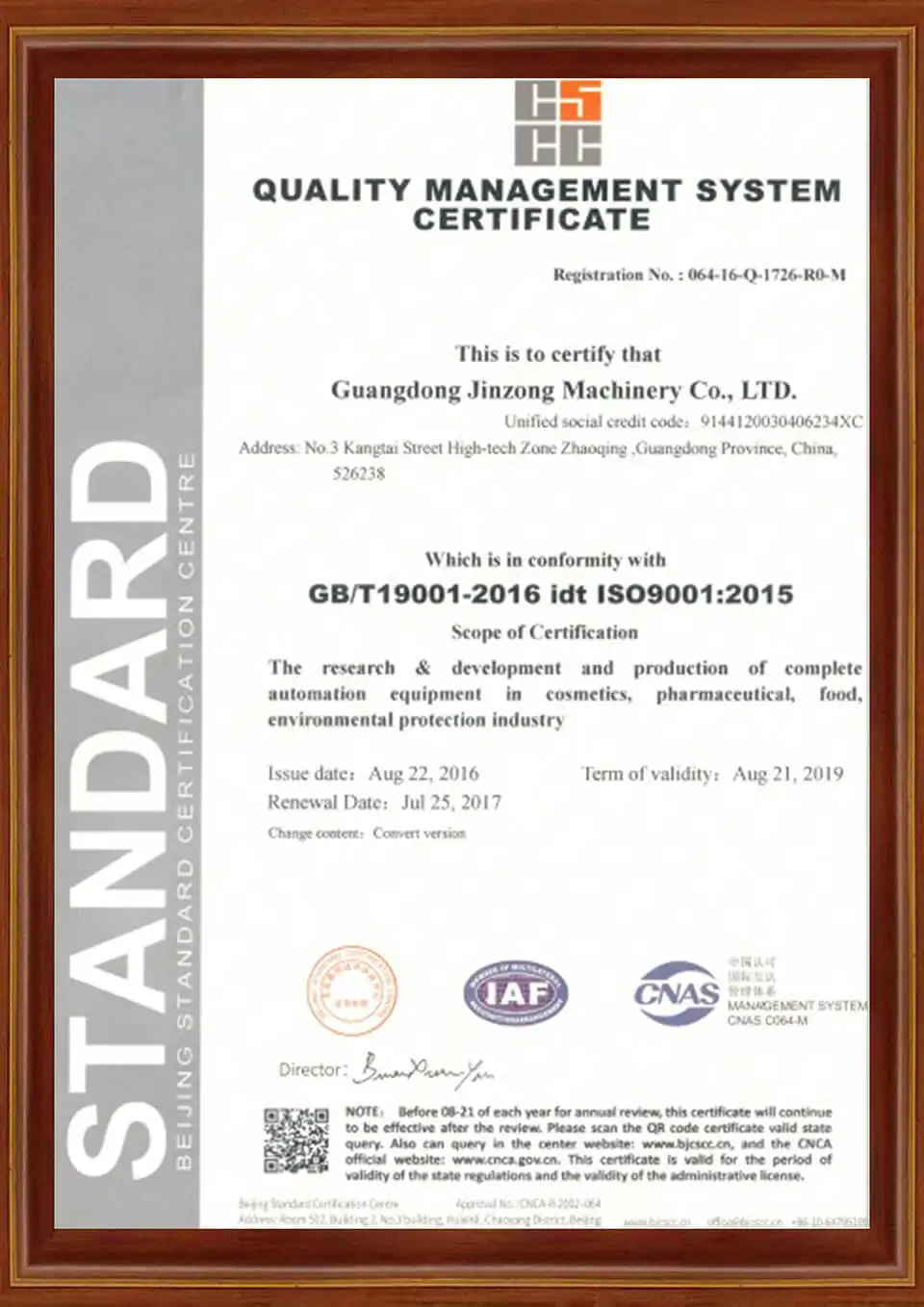

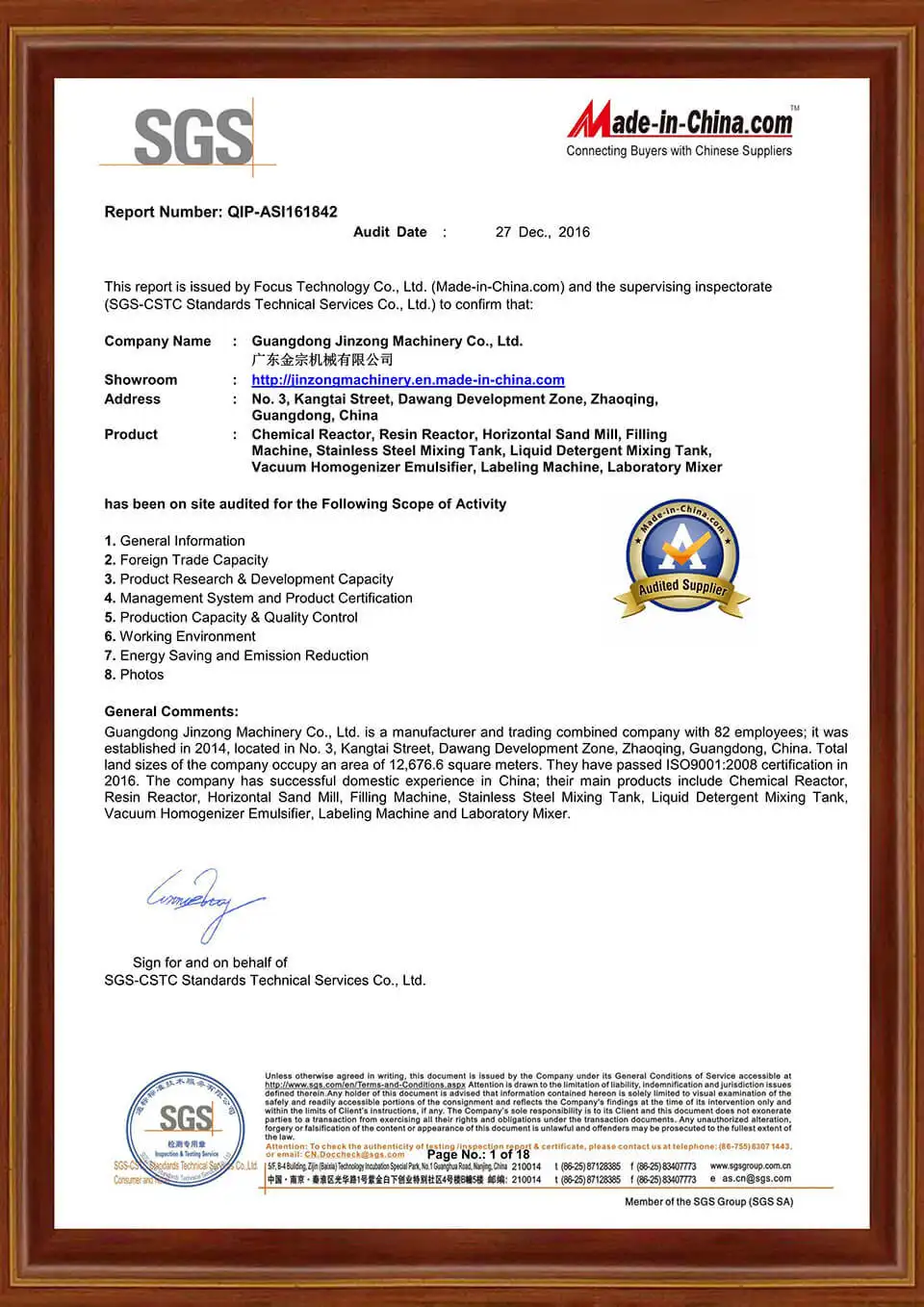

Company Features

1. Holding dominant position, Jinzong Machinery has become one of the important powder mixer machine suppliers.

2. We are equipped with state-of-the-art R&D and technical support departments. They can help design and manufacture new products or improve products that have already been created.

3. Aiming at creating more values for customers through high quality powder mixing equipment has been always kept in each Jinzong Machinery's mind. Contact! Jinzong Machinery enjoys great reputation for its professional service. Contact! The service accomplishments of Jinzong Machinery needs to be achieved by professional staff. Contact! Jinzong Machinery is equipped with professional service team to serve customers well. Contact!

A. Technical service

1, We calculate the capacity and recommend the best models.

2, We supply you the professional refrigeration technical support and electronic technical support for your installation, debugging and operation.

3, We supply the spare parts and technical support in & after the warranty time.

4, We supply the training course to your workers at our factory if you need.

B. After-sales service

1, Technical support for your installation, operation and maintenance.

2, One year’s warranty, and you can pay for extended warranty.

3, Spare parts and technical support at most economic prices after the warranty.

This machine is applicable for mixing of powder and granulate material in pharmaceutical, chemical,foodstuff, ligh industry, electronic, mining and metallurgy, national defense industry and scientific research institutes.

Working principle :

This machine is composed of base, governor motor shaft, rotary connecting rod and barrel etc., material.barrel is driven by the positive shaft to make complex movement including horizontal move, rotation and roiling etc, which makes the material moved to 3 directions along the barrel, therefore, highly uniform mixing of various material is realized. This machine is a kind of full closed high effcient energy saving mixer without germ and dust. When he material is being mixed, no centrifugal force effect and situation of gravity segregation and laminar accumulation are occurred. In addition, it has larger loading capacity,short mixing time and high efficiency.

Parameters:

Model | SWH-1 | SWH-5 | SWH-15 | SWH-50 | SWH-100 | SWH-200 | SWH-400 | SWH-600 | SWH-800 | SWH-1000 |

Capacity(L) | 1 | 5 | 15 | 50 | 100 | 200 | 400 | 600 | 800 | 1000 |

Max.Loading Capacity(L) | 0.8 | 4 | 12 | 40 | 80 | 160 | 320 | 480 | 640 | 800 |

Max.Loading Weight(kg) | 0.4 | 2 | 6 | 20 | 40 | 80 | 160 | 240 | 320 | 400 |

Speed OF Driving Shaft(r/min) | 15~30 | 8~15 | ||||||||

Motor(kw) | 0.12 | 0.25 | 0.37 | 1.1 | 1.5 | 2.2 | 4 | 5.5 | 7.5 | 11 |

Size L*B*H(mm) | 500*600*600 | 600*1000*1000 | 700*1000*700 | 1000*1400*1200 | 1200*1700*1500 | 1400*1800*1600 | 1800*2100*1950 | 1900*2100*2250 | 2200*2400*2300 | 2250*2600*2600 |

Total Weight(kg) | 50 | 150 | 200 | 300 | 500 | 800 | 1200 | 1500 | 2000 | 2500 |

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)