Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

high quality Vacuum mixer Guangzhou high speed for nanometer materials

1. To ensure the quality of Jinzong Machinery cosmetic mixer equipment , the first-rate materials are used in the production, which acts as an important role in guaranteeing the basic quality assurance.

2. The economic benefit of Vacuum mixer Guangzhou used as cosmetic mixer equipment is evident.

3. cosmetic mixer equipment can be widely applied to different fields.

4. With a fine image, outstanding staffs and top-notch quality, Guangdong Jinzong Machinery Co., Ltd. offers wholehearted service to clients at home and abroad.

5. Guangdong Jinzong Machinery Co., Ltd. has a very strict inspection system to ensure quality.

*Description:

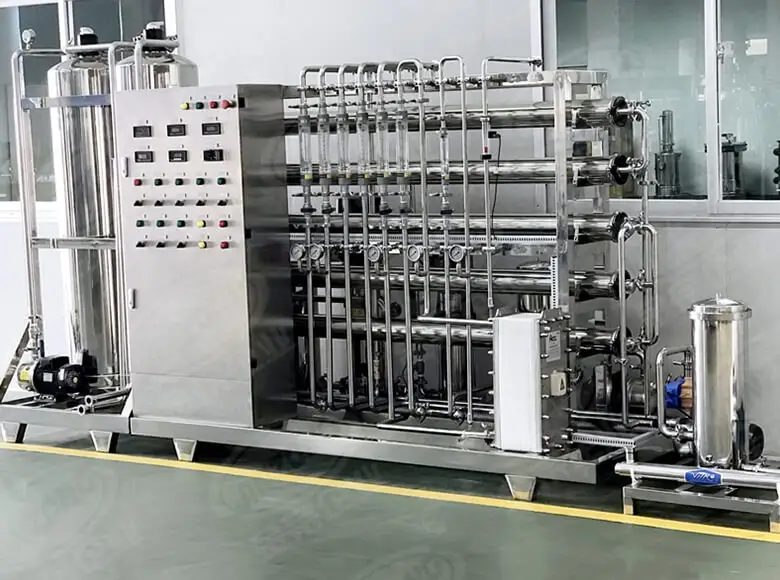

The water treatment machine is suitable for such industries as cosmetics, pharmacy, food and electronics has been deeply favored by users for its stable water quality and simple operation.

The system solves the troubles of frequent regeneration and cleaning during the use of ion exchanging water purifier. By adopting physical principle, it enables the water to pass the reverse osmosis film with a diameter of one ten-thousandth of a micron and separates impurities, ion, microbes and colloids in the water, so as to meet the water requirements in cosmetics industries.

Reverse osmosis process uses semi permeable spiral wound membranes to separate and remove dissolved solids, organic, pyrogens, sub micron colloidal matter and bacteria from water. Feed water is delivered under a pressure of approximately 16 kg/cm2 through reverse osmosis membranes. Water permeates the minute pores of the membrane and is delivered as purified water. Impurities in the water are concentrated in the reject stream and flushed to drain. Reverse osmosis is capable of removing 90%-99% of total dissolved solids (TDS), 99% of organic, including pyrogens, and 99% of all bacteria in the feed water.

According to the customer's local water testing report,we adopt different equipments to produce drinking water of pure water or mineral water,etc.

*Features:

1. Continuous production, no need to regenerate, reduce labor intensity;

2. High efficiency, fully automatic operation, easy to operate and maintain;

3. Online conductivity monitoring to ensure that the water output meets the requirements;>

4. Can remove organic matter and bacteria more than 98 %;

5. If the original water quality is poor or the water demand is high, JRO reverse osmosis can also be connected with ion exchange equipment to ensure various water requirements.

6. Can add anion & cation mixing bed,EDI,UV lamp,etc..

| Model | Productivity(t/h) | Power(kw) | Recovery rate(%) | Desalination rate(%) |

| JRO-0.5 | 0.5 | 1.5 | 50 | 97 |

| JRO-1.0 | 1.0 | 1.5 | 50 | 97 |

| JRO-2.0 | 2.0 | 1.5 | 70 | 97 |

| JRO-3.0 | 3.0 | 2.5 | 75 | 97 |

| JRO-5.0 | 5.0 | 5.5 | 75 | 97 |

| JRO-6.0 | 6.0 | 5.5 | 75 | 97 |

| JRO-8.0 | 8.0 | 7.5 | 75 | 97 |

| JRO-10.0 | 10.0 | 7.5 | 75 | 97 |

Chemical industry, power plant desalination water, electrodeionization ultra pure water, medical industry, aviation cleaning, food and beverage industry, municipal heating,

softened circulating water, living water purification, brackish water desalination, sea water desalination,industrial waste water treatment, reclaimed water reuse, rural area drinking water project, pharmacy inductries,etc.

Company Features

1. Guangdong Jinzong Machinery Co., Ltd. is a company specializing in the production of advanced cosmetic mixer equipment .

2. We have expanded our business scope in the foreign markets. They are mainly the Middle East, Asia, America, Europe, and so on. We have been making efforts in expanding more markets in different countries.

3. Jinzong Machinery has great ambitions for the development of the cosmetic machine market. Get quote! Jinzong Machinery has always followed the rules of customer first. Get quote! In Guangdong Jinzong Machinery Co., Ltd., endless attempts have been made to foster the evolution of the national Vacuum emulsifier business. Get quote! Our goal is to become an international Vacuum mixer Guangzhou exporter. Get quote!

JINTAI JHX cosmetic making equipment / body lotion mixer

Zhengzhou Jintai Metal Material Co.,Ltd is an innovative manufacturer for Mixing machine.JIN HE® JHX series double movement mixer is a national patent product and has proprietary intellectual property rights.it is used for the homogeneous mixing of powders or different components with differing specific weights and particle sizes.

Compared with tridimensional mixer,double cones mixer and V type mixer,our mixer has double movement systems(barrel rolls in horizon axis while the blades inside the barrel blends in oblique axis) which means it can mix materials more efficiently and 100% no dead angle. As customers test the innovative mixing machine we created has amazing performance, the advantages of our double movement mixer are

High quality in mixing effect,100% no dead angle

High capacity(the charging rate can reach to 75% for its unique operating system)

Time saving(save 50% time to meet mixing criteria)

Money saving(saving time 50%,electricity 70% and 30% space)

cosmetic making equipment / body lotion mixer

There is a specially made sealing component between the shaft and the container. When discharging materials, the container revolves within a small arear through button panel to make ribbon blade stir,accelerating the discharging process. All internal components involved in the process of mixing are made of stainless steel.

1. High mixing efficiency, when compared with conventional mixing equipment, mixing time can be shortened by more than 60%, and power consumption can be reduced by 20%-30%;

2.For the mixer has a small turning radius, and low feeding inlet that located directly above, so compared with Vtype mixer, it’s easy to use and has low labor intensity.

Because the discharge opening is designed with gate valve and plus the two pyramidal angles of inclination in the top and bottom of the material barrel, the discharge is very convenient.

3. For safe operation, this equipment is especially set with double bond of safe mode of operation. Only press the “get ready” button and the “run” button at the same time, the equipment can only be working. Thus puts an end to the unintentionally touching by people.

4. Because this mixer has a comparative small barrel turning radius, it takes a very small room, and has a better security compared with V-type mixer.

5. Since the force generated by the revolving of ribbon blades can push the light powder into the heavy powder, mixing materials with different specific gravity will be much more efficient.

cosmetic making equipment / body lotion mixer | Barrel Capacity (L) | Max Barrel Capacity (L) | Max Barrel Capacity (kg) | Barrel Speed | Blade Speed | Motor Power | Size (mm) | |

JHX50 | 50 | 35 | 60 | 25 | 50 | 1.1 | 1500×620×1000 | 430 |

JHX100 | 100 | 75 | 110 | 23 | 46 | 1.1 | 1700×720×1200 | 500 |

JHX200 | 200 | 140 | 240 | 21 | 42 | 2.2 | 2050×830×1400 | 660 |

JHX400 | 400 | 280 | 500 | 17 | 34 | 3.0 | 2500×1010×1600

| 910 |

JHX600 | 600 | 420 | 700 | 17 | 34 | 4.0 | 2700×1120×1750

| 1200 |

JHX600Z | 600 | 420 | 1000 | 14 | 28 | 5.5 | 2700×1120×1750

| 1400 |

JHX800 | 800 | 560 | 800 | 14 | 18 | 5.5 | 2900×1200×1850 | 2000 |

JHX1000 | 1000 | 700 | 1000 | 11 | 22 | 7.5 | 3200×1300×2070 | 2300 |

JHX1500 | 1500 | 1200 | 1500 | 11 | 22 | 11 | 3600×1500×2300

| 2800 |

| JHX2000 | 2000 | 1600 | 2000 | 11 | 22 | 11 | 3900×1600×2800

| 3200 |

....

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)