Jinzong Machinery | Cosmetic Machinery & Chemical Machinery Manufacturers

high-quality powder mixing techniques jr supply for food industries

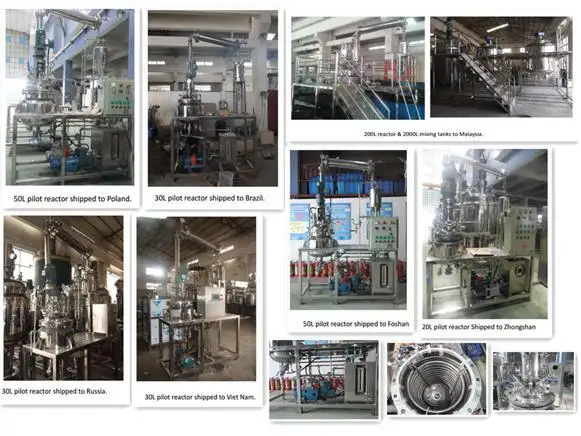

Pilot reactor:

Material:SS304, 304L, 316 or SS316L

Design Pressure:-1 -10 Bar (g) or ATM

Work Temperature:0-200 °C or customized

Volumes:5~200L, customized

We can provide users with engineering design, equipment model selection guide, equipment machinig, equipment installation and turn-key project from pilot plant to large scale manufacturing plant.

*MAIN COMPOSITION of pilot reactor:

Pilot is mainly composed of Reaction vessel, mixing system, vacuum system, condenser, receiver/storage tank, conduction oil preheating system, platform, etc.

Heating and cooling method: 1. Heating and cooling by jacket. 2. Heating by jacket and cooling by inner pipe coil.

Type of electrical device: 1. Ex-proof type. 2. Normal type

Electric cabinet control mode: 1. Touch-screen control. 2. Button control

*pilot reactor small scale reaction plant performances and features:

◪ Design compliance with cGMP.

◪ , Long operational life, Less maintenance

◪ Excellent functionality;

*pilot reactor:

It is widely used for reaction, evaporation, concentration, synthesization, polymerization, mineratization, etc. in pharmaceutical industry, chemical industry, dye, pesticide, organic synthesis, petroleum, food additives, industry of national defense and scientific research.

Tel: +86-758-3623881

E-mail: sales@jinzong.com.cn

Fax: +86-758-3623880

Address: NO.3 Kangtai St., Hi-tech Dist., Zhaoqing City, Guangdong Province, China(526238)